Good call, its paid for itself 10x over so I guess it can be held onto for those random wooden mold making projects that come up. The HDM is so great at aluminum I don’t think the pro will ever see metal again!

I was on the same fence but with my fully upgraded So3 with HDZ and currently she sits idle but ready if needed. I don’t think I want to listen to the high pitch sound of the router cutting ever again now that I have been spoiled by the low noise of the water cooled spindle life.

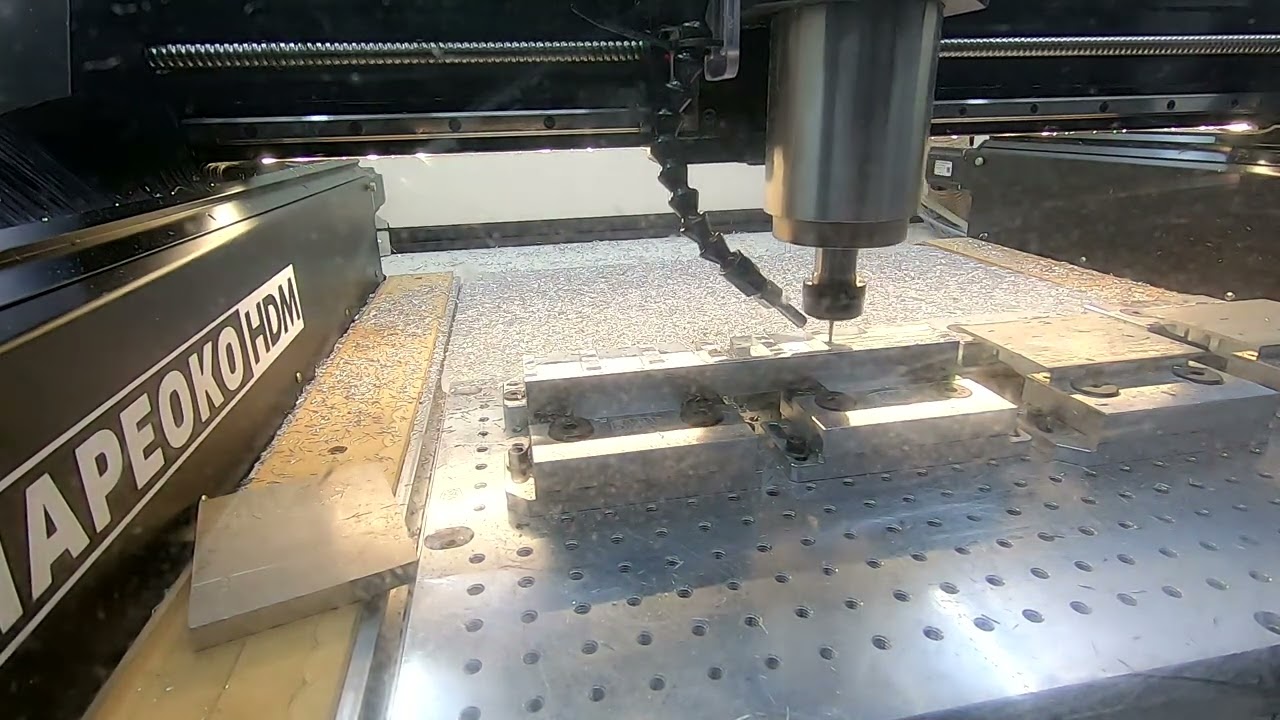

Back at some new parts that I designed on the plane. 2D Contour slotting in 6061 with Fusion 360 Ramp Feature and it cuts quick and awesome! 1/2" Stock and fully cut and finished in about 8 minutes total. 4"x7" of stock

Looking good! I got my HDM and doing the deep dive into the world of CNC. I’ve been making parts for years for others to machine, just never got to do it myself. Thanks for sharing all the fun stuff you’ve been building for the Porsche! I’m limiting myself to just learning on foam for now so I can make all my mistakes before getting to the good stuff. I’ve been going down the list in fusion to learn about the toolpath strategies. Lots of experimentation and trial and error in there. It’s so much fun!

Once you start to cut your own parts its so rewarding. We build custom parts and work on full custom Porsches for clients. Today I design, cut and installed some new aluminum speaker mounts, bumper mounts for rallye lights and shock canister mounts for remote shocks. Not having to wait to cut and test parts speeds up the process so much

.

That’s excellent! It really is amazing how fast you can have a working part on a car with this setup. I’ve been going through some exercises in foam with 2d tool paths yesterday, some 3d tool paths today. Taking baby steps through tool changes, maybe tomorrow I’ll try out a flipped part. Super exciting! I was wondering how you might like to keep stock around? I was going to head down to the local metal shop tomorrow and see if they might have a scrap bin I can dig through for some stuff, but I can certainly order some. What do you recommend?

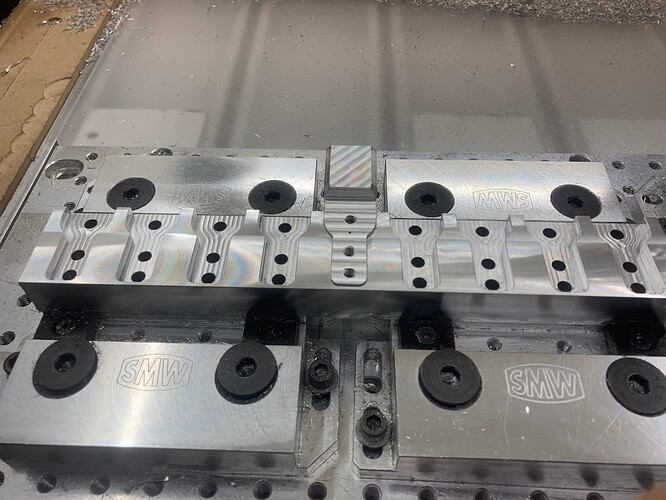

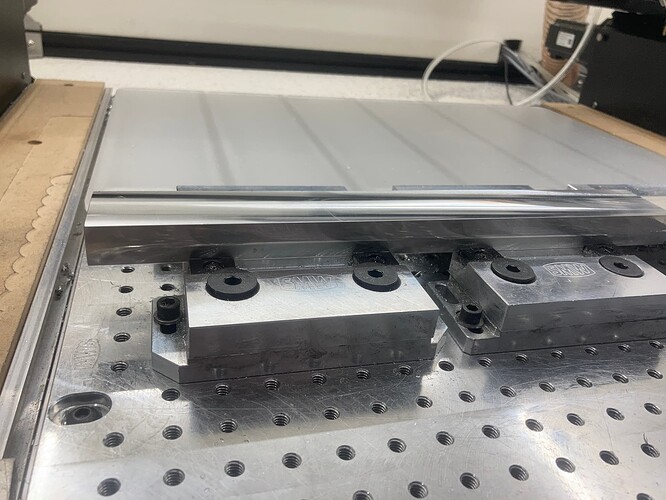

I love the look of freshly milled aluminum. Just a upright part holding soft jaw / jig to hold my parts so they can be drilled and bored to spec. This is the last setup for my first 3 sided parts. The parts sit in the pocket and through bolted from the back then will be held in the vise with another soft jaw. It’s probably over kill but I don’t want them pulling out when drilling so the bolts will make sure that can’t happen.

That looks so awesome! Love

On the second set I really started pushing my 1/8" C3d Zrn coated end mill and was really surprised by how hard I could run such a small tool.

2d adaptive .125" Zrn Single Flute at .25" Doc, .018" stepover, 20k rpm, and with the feed override I settled on 88 ipm. I was waiting for it to jump to the spirit realm but it cut with no issue but I only have one so I wasn’t willing to push harder. I will post a video as it ran over 30 minutes in the cut at that feed.

I started at 55 ipm and ramped up to 88 by ear it ends up being .0044 chip per tooth.

The stepover / optimum load was .018" not .025"

Was that the single flute or two flute cutter you were using at those rates?

274Z Single flute with air blast and Coollube 2210AL. I think cutting that heavy dry would cause a failure.

Well I had to run another duplicate fixture after this video and bumped the feed rate up to 99 ipm and it went smoothly for 40 minutes with great results but it’s now limited by the machine acceleration in short pockets but still beyond what I thought such a small tool could do. No room for errors going this fast at 2x the tools diameter in depth of cut though. That’s over .0045" chip load.

Today I used my PRO for the first time in a while, some templates to plasma cut some parts, made out of wood. I am taking all the mist setup off my pro, will never try to cut aluminum with it again.

Has anyone found a reliable way to stop or slow chips getting in the Y Axis Areas? I tried the Brush’s setup and it works ok, but would love a better solution. Is there a boot or cover that could help around the bit area?

Quick design and cut of a billet aluminum oil access cover, ran at 150 IPM, 0.1” DOC with a 0.05 cut and ready to Powdercoat in 25 minutes

It’s amazing seeing what people are producing here using the HDM. I’ve been using it for about two months now and this monster just eats up aluminum. What an awesome machine.

Today I had a visit to the shop that was local to me, wanted to see how the HDM works and honestly it made me realize that the HDM is an amazing machine for cutting aluminum and it has changed my business for the better. Prototypes, production, everything I throw at it is amazing

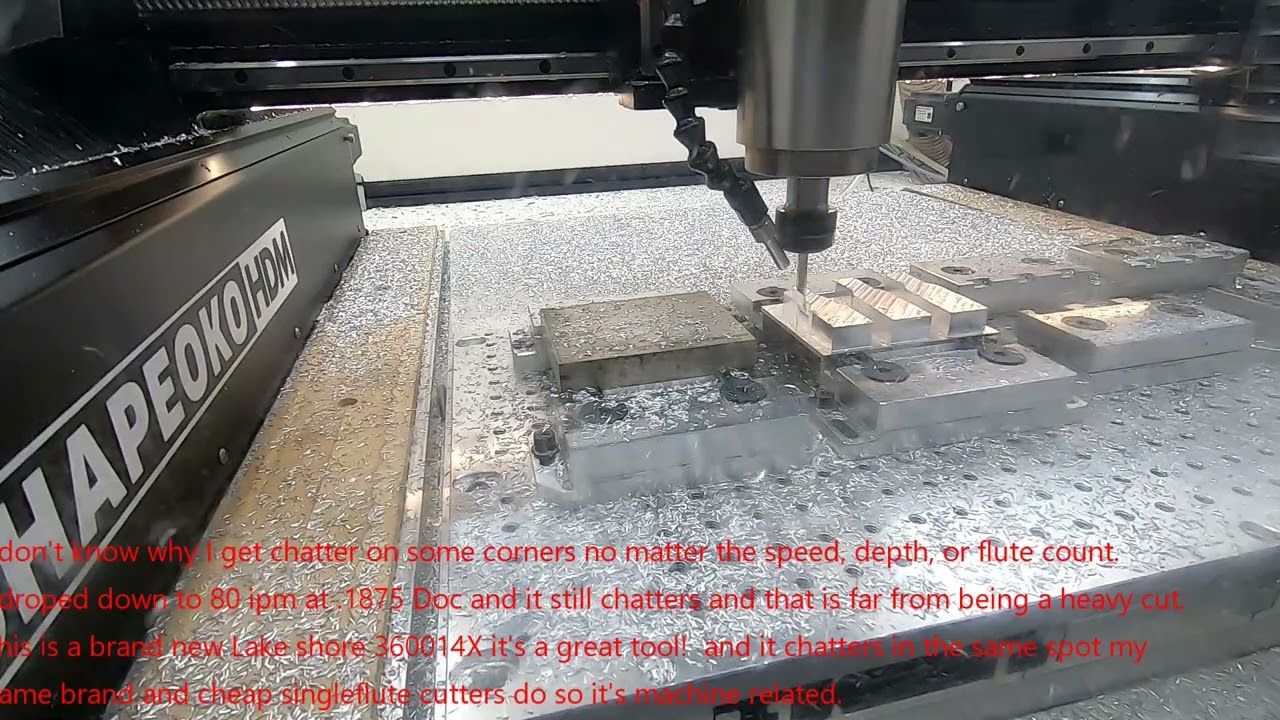

I see in your 150 ipm video you get chatter in the corners and I’m having the same issue. Every part of the cut sounds great until the corners. It doesn’t matter if I’m using a 6mm single flute or a brand new .25" variable 3f with chip breakers it does this. Even going from 1/2" Doc to 3/16" and slowing down to below 80 Ipm at only .035" stepover. My machine also has a strange resonance when jogging using the pre set CM points but only when going diagonally it vibrates the entire enclosure like a speaker.

Any ideas why this happens?

I do like Lake shore Carbides variable flute chip breaking rougher finisher mills with the .005" corner radius. They are chip slinging beasts when properly cooled and they leave a pretty damn nice finish.

I did murder 1 by being greedy with the feed override and not adjusting my mister in the narrow portion of the roughing operation to properly hit the tool and chip welded it at 140 Ipm at 24k .55" Doc .035 stepover adaptive. Ended up running 110 ipm with it’s non corner radius brother.

Video of the Murder so be warned it contains graphic content / abuse of an innocent end mill.

I do have some Lye on the way to see if he can be some what revived but we will see.

The chatter in the corners is interesting. Especially being an outside corner?? I have a shapeoko3 with the steel core 10mm belts with a similar situation. If cutting a circular pocket in aluminum, it only chatters at about the 1:30 and 7:30 positions. doesnt seem to happen (at least not as pronounced) at the 10:30 and 4:30 positions. fast feed, slow feed…1 flute 2 flute…etc and all at much more conservative parameters than what you are running.

I chalked it up maybe some loose v-wheels or something. but seeing a similar phenomenon on an HDM does have me wondering. The search continues!!

Does your resonance happen when jogging in both diagonal directions?

I am looking at using the option in Fusion to slow the tool path on certain parameters like when doing an outside corner, etc. I will test this week and see what I can do