While it’s quite straight-forward to make MDF filler strips on an XL:

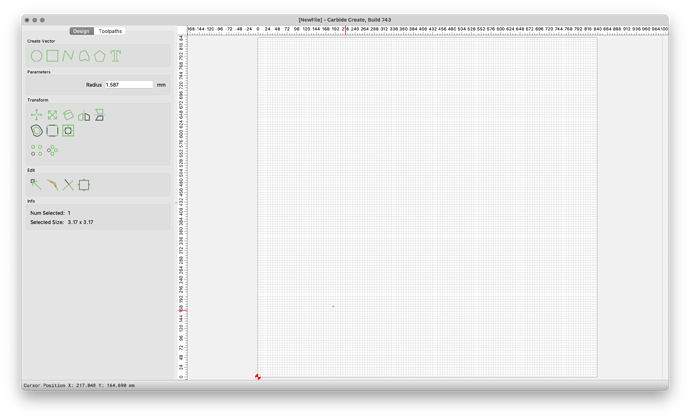

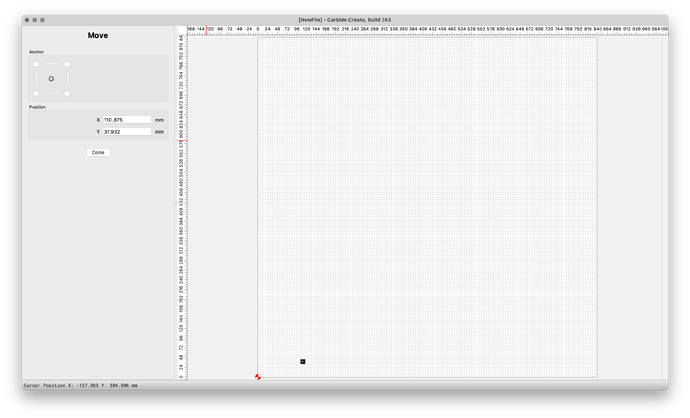

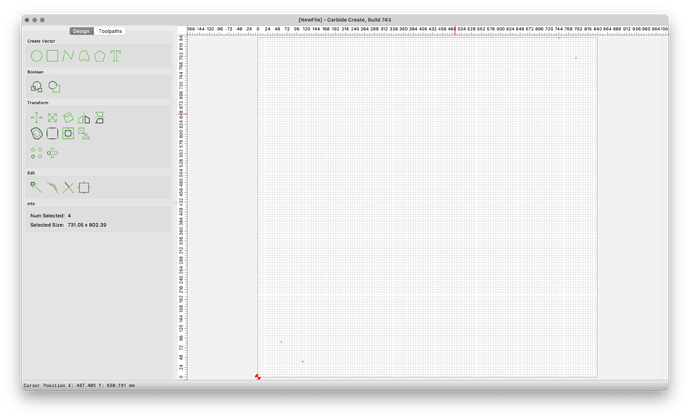

Geometry isn’t so kind on an XXL or Standard w/ their essentially square bed.

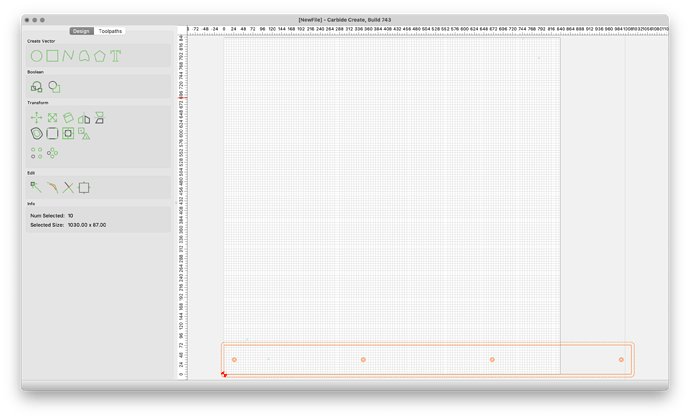

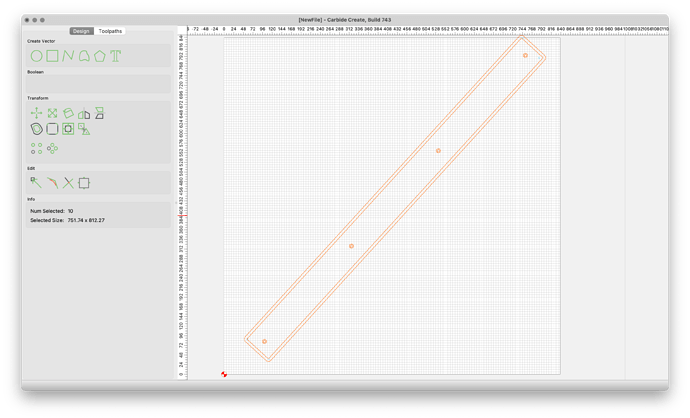

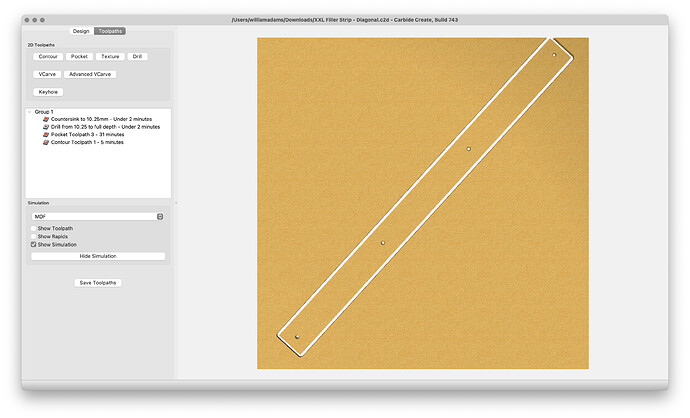

Making replacement filler strips requires that one do a bit of rotation to make things fit, and source narrow boards, rather than large sheets.

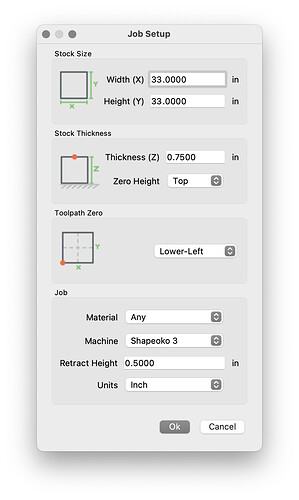

First, go to the local lumber yard and buy a board of suitable dimensions (greater than 40" in length, wider than 3" or so, and as close to the 3/4" thickness as is possible). One option is Azek “Exterior PVC Trim 1 x 4 x 8’ (nominal dimensions, actual dimensions: 0.75-in x 3.5-in x 8-ft)”:

https://www.lowes.com/pd/AZEK-Actual-1-in-x-3-5-in-x-8-ft-Trim-Board-PVC-Board/1000507559

That a 4x8’ sheet is only a bit more:

is an interesting look at the economics.

Another option is MDF boards — these are more affordable, but aren’t as thick, and usually are pre-primed.

If you don’t have a truck or van, bring a handsaw (or buy one while shopping) and cut it in half or so that it will fit in one’s vehicle (probably best to cut a bit longer than 40" so as to maximize the length of the final off-cut):

Necessary tools:

- 4mm hex key (to remove and replace MDF filler strip)

- hand saw

- Shapeoko w/ trim router and suitable endmill

- suitable workholding

Necessary materials:

- suitable lumber

- MDF filler strips in need of replacement