We cut the holes and do the math, and send the new values for $100 and $101, then re-cut the holes to verify — with the new holes both measuring at 99.99 we call it close enough.

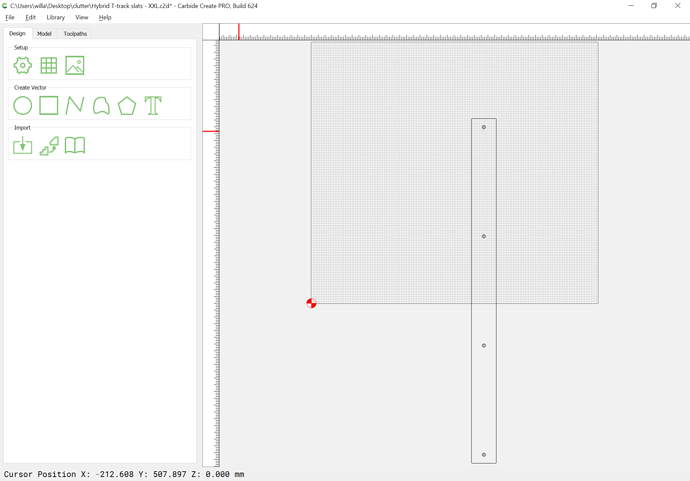

Next, in CM move to the SW point and set XY origin there.

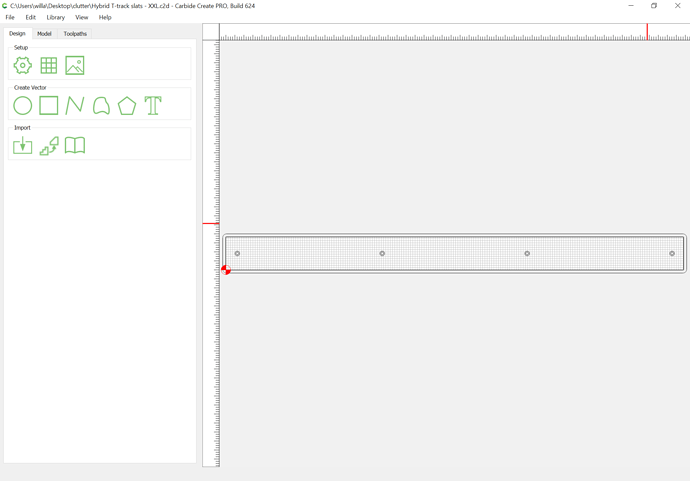

Then we load a drawing of the hybrid T-tracks:

Hybrid T-track slats - XXL.c2d (110.5 KB)

(it would be great if someone would measure the slats on a standard/XL size machine)

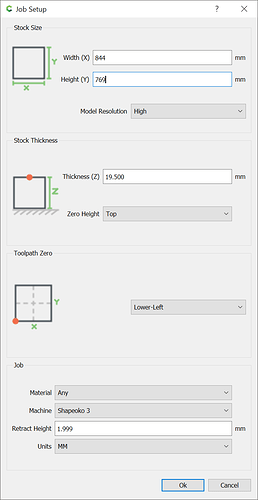

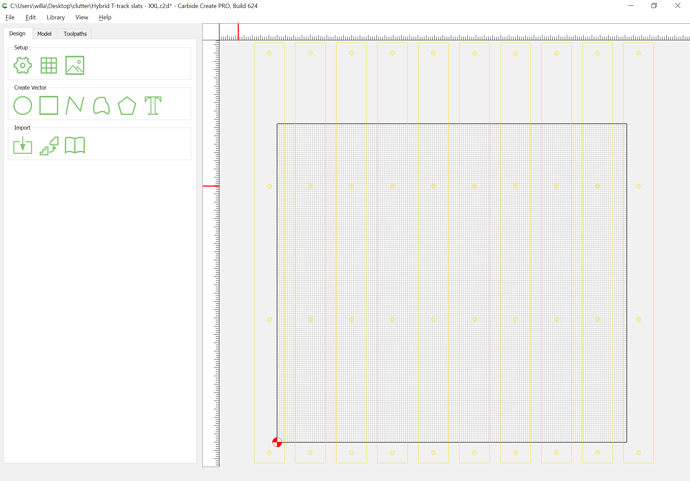

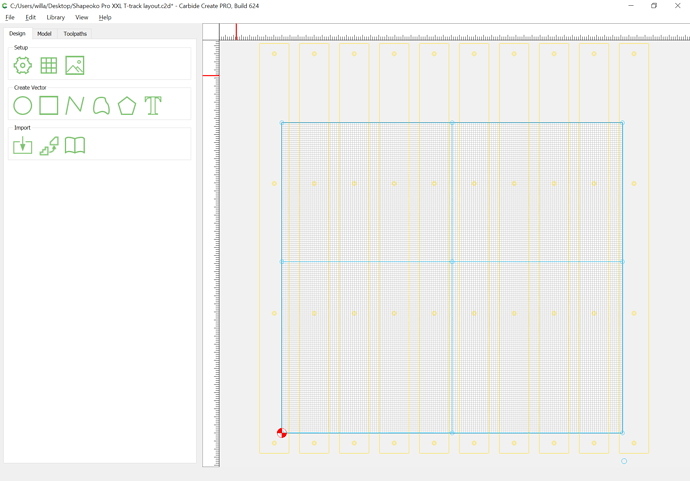

and simplify and rotate it and set the stock size to match the rapid position points:

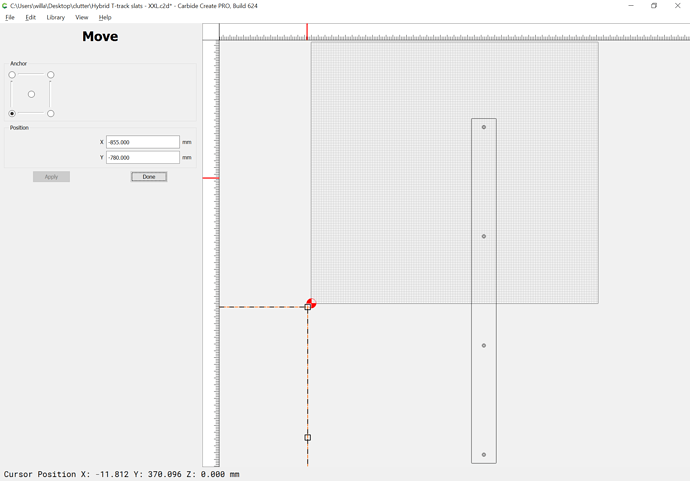

Now we move the machine to determine the location of each MDF filler strip, and position copies of the MDF filler strip graphic appropriately — the easiest/most accurate way to do this is to put CM into machine coordinate position by clicking on “Position” which then shows the origin as being X -855, Y-780 (there are tiny decimals due to the calibration for belt stretch which we are ignoring)

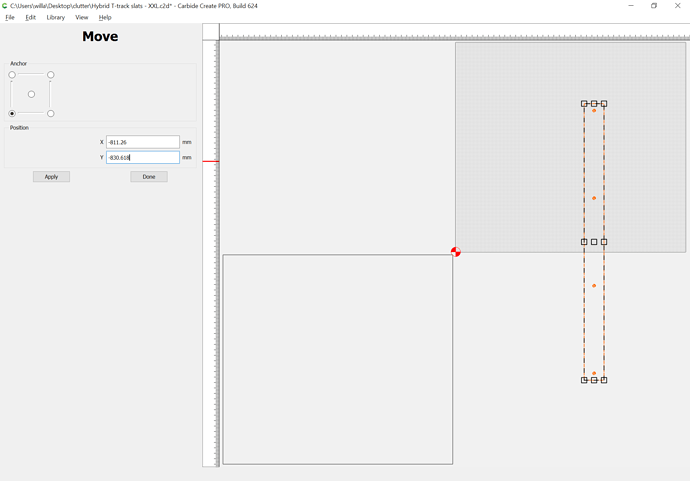

We then probe for each MDF filler strip origin using a probing pin and a BitZero v1: X -811.26 Y -830.618 for the first one:

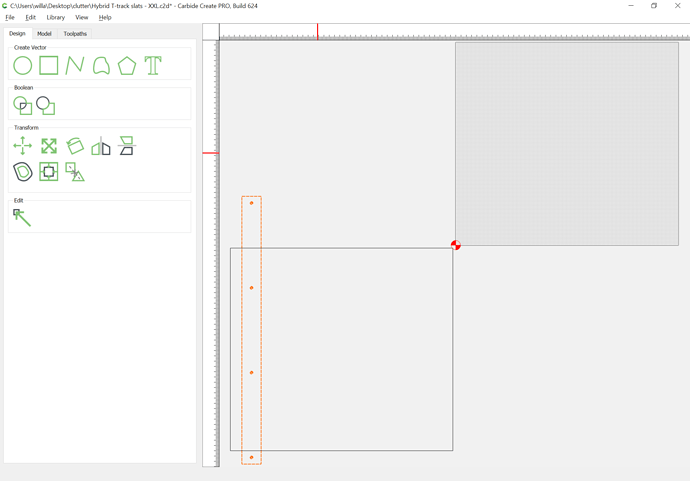

and we repeat for each and make a layer to put them on:

and make a layer for the rapid position points as well as the BitSetter: