Great ! I remember I also wondered about how to set PD144 correctly initially, it’s not the most intuitive parameter.

20640 for 20K is precise enough indeed.

Great ! I remember I also wondered about how to set PD144 correctly initially, it’s not the most intuitive parameter.

20640 for 20K is precise enough indeed.

Will it still run at 24000 RPM?

@gmack, it appears so, I put 24000 in and 24000 showed up on the screen. Now I can’t actually measure it but it seems to be working as advertised.

Weird! Is “PD176 = 0 ; 0 = 50 Hz = inverter frequency standard; read-only”?

Yeah I tried to change it to 1 for 60 Hz but it wouldn’t let me.

Doesn’t PD144 change it?

You guys are trying to “fix” something that isn’t broken. You know that right?

don’t inverters go to DC internally and then go back to AC

(so the wall socket frequency is not relevant)

A colleague recently got a 800 Watt G-Penny spindle for his Shapeoko XL. He can’t get it to go faster than 20,000 RPM (50/60 * 24000 = 20000). (He’s the kind of guy that would measure speed with a tachometer.) The manual and settings imply that Huanyang uses the power line frequency as a frequency standard (rather than an oscillator).

Interesting. I’m still in the construction phase of my Shapeoko Penthouse, but will be starting on the electrical part of the install eventually. I also have a 220V G-Penny here is the US. Curious about the PD144 and the PD176. I was going to use 3600 Hz also. ??? hmmmm

Get one of these and you’ll know for sure what your spindle is doing! Or you could go “old school” with a Strobotach. It seems that someone using one of those VFDs in the US knows and could clear this up? There seems to be quite of few users here.

Been following this for a while now. Just broke down and ordered a 1.5kw water cooled spindle. Wanted a 2.2 but for the collet size but decided it wasn’t worth the weight.

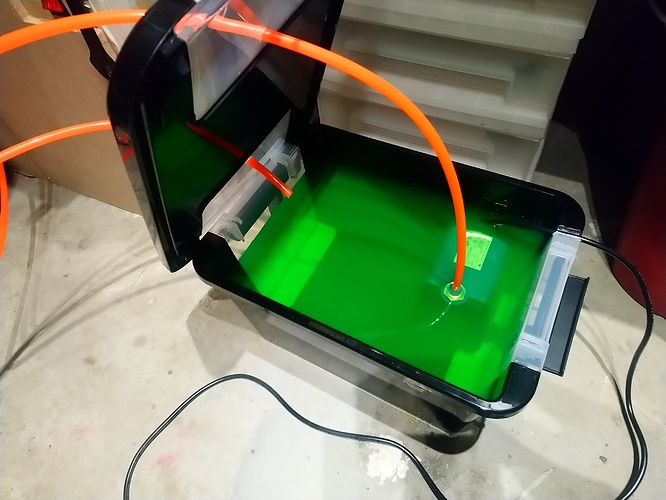

How much heat is put off by one of these? I’m planning on running a bucket system to get it going. I do not plan on keeping it that way though. I’m just curious if a radiator is needed or if just a quart Reservoir is enough ?

A 20l reservoir shouldnbe ample to keep it around 20. Just make sure it has a lid over the bucket

I used this for a year without any issues with my 2.2kW spindle:

It had 9l of antifreeze in it. 20l as Luke says will give you even more thermal margin.

EDIT: latest news is that spindles may like to stay under 35°C, and with those 9l of coolant with no active cooling it takes about 5 hours under light (but continous) load to reach that value.

side note: being from the old world I had to look-up how much a “quart” is, and google says it’s 0,946353l, is that how much a “quart reservoir” would hold ?

I feel so inadequate running a 600ml PC cooler on my 800W spindle.

It only felt warm even after a large job.

Yes. That’s what a quart is

I’ve just about finished making a beefier Z axis for my machine to hold my new 1.5kw spindle. The manufacturer recommends a procedure for when you turn on the spindle of increasing the speed over a period of time. My question is do you run this warmup only once when you first turn on the spindle (as a run-in process) or every time you turn on the spindle as a warm up for cutting a project?

I’ve got a 2.2kw spindle - it ramps up to the speed setting over a short period of time (maybe 2 or 3 seconds?). You can tinker with the settings in the VFD to adjust the ramp up time to whatever you want. I’m pretty sure mine is just at the default settings - and I don’t really have a reason to change it.

There are two things:

EDIT: Here’s the discussion I was referring to, and here’s my daily spindle warmup macro.

The VFD microprocessor’s crystal is likely the “inverter frequency standard” for its output frequency. But, PD144 appears to be the parameter that enables it to properly display spindle speed.