Yeah, I’ve only ever used the Nomad 3 to be completely honest.

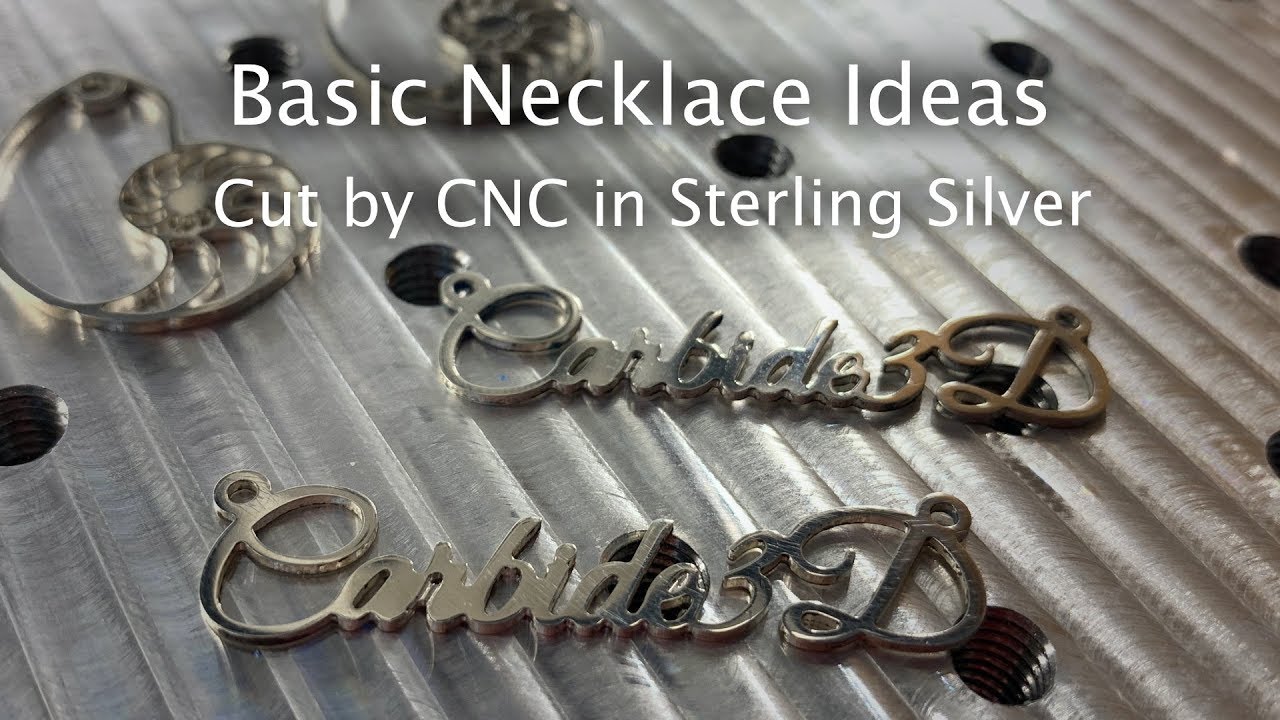

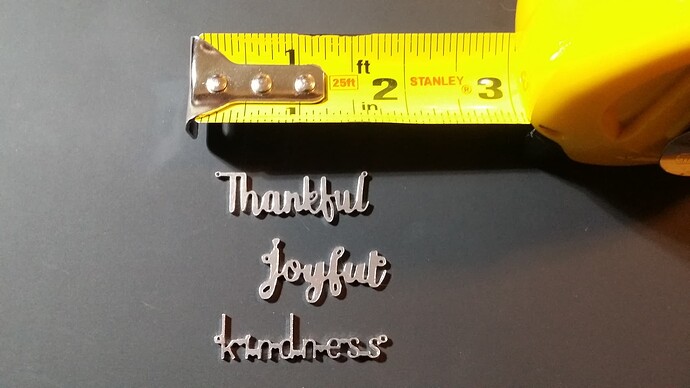

Most of the work I do is relatively small and in various types of metal. (Copper is a nightmare but aluminum, brass, zinc are all quick and easy enough)

I also use a fair amount of wax for prototyping, no jewelry wax yet but plenty of other folks have.

Unfortunately I can’t speak to materials like stainless…yet.

My cutters range in size from ~0.5mm to 1.5mm. The relatively high rpm (24000) is greatly appreciated when using tooling this small.

Any of the larger work i do would likely be better served by your shapeoko. (1/4" tooling through acrylic for example)

The workflow for the nomad with the integrated tool length probe and the well lit enclosure is really quite good. Especially once I’ve got a jig made for a project I’m going to repeat a number of times. It’s just a pleasure to use, which is one of the highest compliments I can give a tool.

I can say fairly confidently that the Nomad 3 was, and still is, the best purchase for me given all of the options.

I really want a fiber laser as well but that’s mostly for deeper etching of very fine text. Most of the work would be done on the Nomad before finishing on a laser.

For you it’s hard to say. Many of the items you’ve mentioned might be better served by a little fiber laser cutter and a tumbler to finish.

If you’re looking to do more than 2 dimensional geometry in fine detail, the Nomad sounds like a good choice to me.

As for the shapeoko vs nomad debate, it comes down to time, patience, and experience.

I’ve seen folks do incredible things with their shapeoko. I’ve done incredible things with my Nomad.

The difference is that they’ve usually got a tremendous amount of knowledge and experience backing them. Conversely, I’m just a hobbyist in my garage with YouTube and a subscription to provencut to guide me.

Having a tool form fit for the task at hand has not just made some of the work I want to do easier… in many cases it’s made it possible (for someone of my experience)

I know that feeling you’ve got right now, deciding what tool to add next. Weighing the value of the capabilities it brings to the table compared to what you can already do. I don’t envy that feeling but hopefully in this wall of text you can find some insight to make that decision easier, one way or another.