Thank you @WillAdams and @Tod1d for your help so far. I don’t appreciate any significant tool deflection with the machine off and the bits are well-seated in the collet to minimize deflection. I’ve tried various F&S, including the defaults, and settings that are slower and faster. I’ve also referenced threads here and here, which have discussed issues with corners on various V-carves.

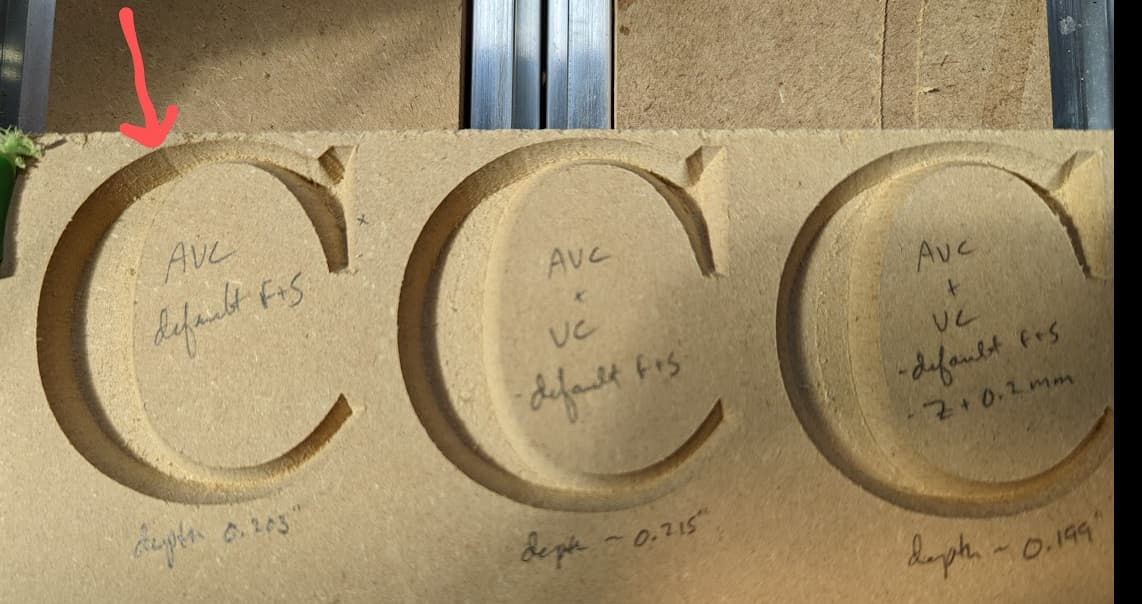

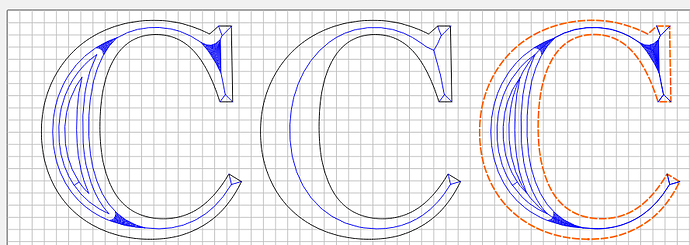

I’ve been able to pretty much resolve the issue by running the original advanced V-carve toolpath, and then running a regular V-carve toolpath. This seems to “clean up” the irregular edges left by the advanced V-carve toolpath. In the image below, the “C” on the left was cut with an advanced V-carve toolpath only and the “C” in the middle was cut with both an advanced V-carve and a regular V-carve toolpath. The “C” on the right was cut the same as the middle “C”, except I raised the Z-axis by 0.2 mm (a tip from one of the other threads). I don’t see much difference in the final cut.

From studying the cuts, the irregularities on the finished product correspond to locations where the advanced V-carve toolpath is trying to create a flat-bottom pocket in spots that are too narrow for the 1/8" endmill to clear. It uses very small stepovers to accomplish this, and as a result goes around multiple times in tiny increments. My hypothesis is that errors are amplified when the bit has so many small direction changes. The regular V-carve is just a single linear sweep through these areas so it leaves a smoother edge (but cannot leave a flat bottom).

These are also areas that are too narrow for the V-bit to reach the full maximum depth. I wonder if choosing a different font (ie, something sans serif) would allow for more consistent depth and reduce this error even more. Will continue to work on this. Thanks again everyone for your help so far!