Hello folks… first-post here! Relatively new to CNC but I’ve figured most everything out, until now.

I’m having an issue that only seems to manifest with v-carving of corners… It occurs in full depth v-carving, or with a flat-depth set (Using Vectric Pro). Seems to happen irrespective of feedrate, depth of cut, or stepover values, or the degree of vbit I use. Essentially any “inside” corner that I cut seems to be offset a bit, and never matches up with the rest of the bevel edge. I noticed it first trying to carve a sign with a vector that was being beveled out with a v-carve path to a flat-depth, but I’ve since boiled it down to simple shapes to try and identify the culprit.

I’m running a Shapeoko 3 XXL with the Carbide Compact router. Using Carbide Motion 4. The images below are from tests I ran on MDF.

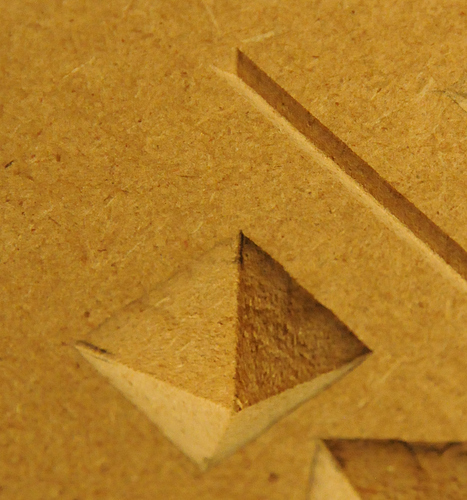

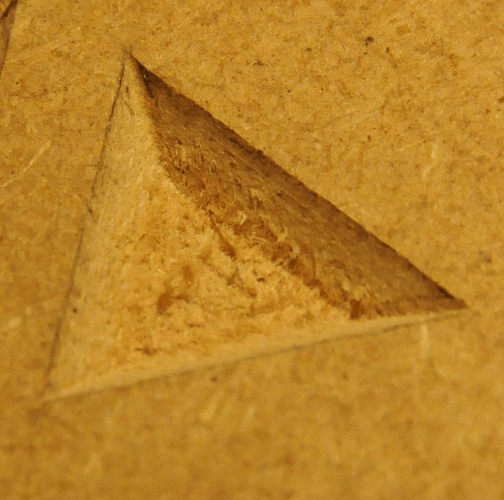

This is an example of what happens in corners when cut at full depth, I was just using triangles as test shapes.

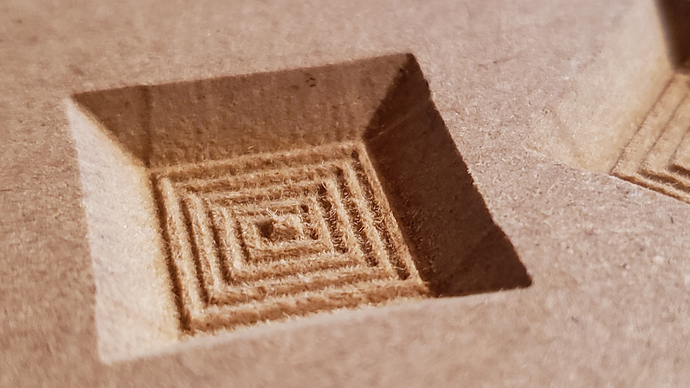

This is what a full depth situation brings - the squares are 3/4 inch width and length, but where the toolpath comes up to finish the corners, it’s .05" wider across. The center of each edge, where it leaves some material, is the proper .75" in size.

I’ve gone over this problem over at the Vectric forums - trying to understand if this is some software issue (I really think not, at this point) or a machine/controller problem. I’ve ran the degree tests, measured my bit, made sure my machine is square, material and wasteboard are flat, etc… I re-read some troubleshooting threads and guides - and today I discovered on eccentric nut on the left Y carriage was slightly loose, so I tightened that up… and realized during assembly I had probably over-tightened some of the other eccentric nuts, so I got everything fixed up.

However, the problem persists and hasn’t changed at all. Any suggestions?

I’ve even opened up the gcode in a third-party viewer to verify everything looks like it should.

(well after I have checked it in a visualizer that is)

(well after I have checked it in a visualizer that is)