helipaddy

October 16, 2023, 9:19am

1

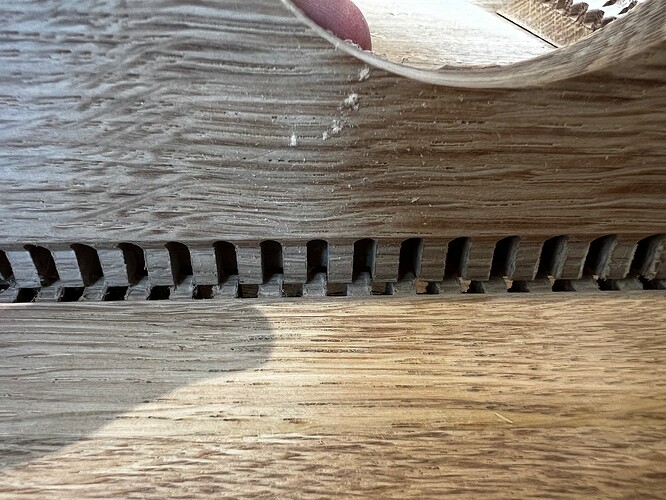

@WillAdams FYI I went ahead and cut this and found that the end pieces could connect ok…

…but that the side pieces definitely couldn’t. Even after a decent amount of cleaning up the tenons are almost a millimetre too wide.

I’m not sure it’s very easy to amend your original file , however I thought other readers ought to know before attempting.

Other than that it was a joy to watch the process. It would be slightly better if there were tiny tabs on the panels because the last run by the V-bit does just about pierce through.

WillAdams

October 16, 2023, 10:45am

2

If you have an SO3/4/Pro have you calibrated your machine for belt stretch?

The typical technique for machine calibration:

https://my.carbide3d.com/faq/belt-stretch/

depends on precision measuring tools, and is limited by the reach of the tools in question.

EDIT:

It also depends on access to the MDI — if using Carbide Motion v6 it will be necessary to enable this in Settings | Options:

[image]

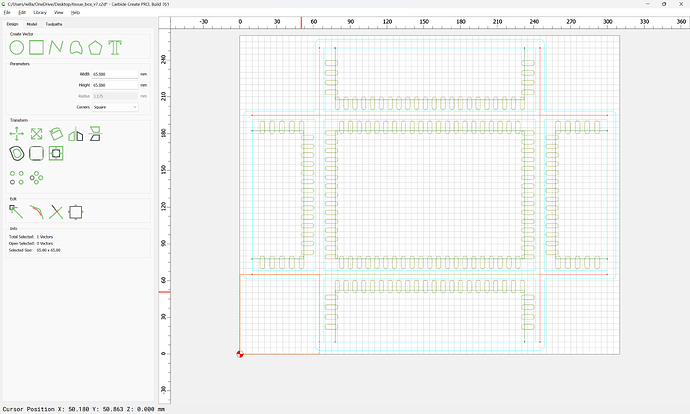

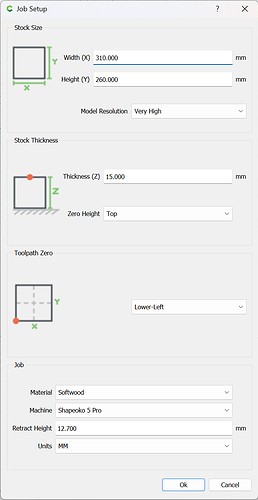

It should be possible to cut strips from a suitable blank of material, one along each axis — so we set up a square file which matches an available blank of material:

[ima…

If not, post the file?

Probably you can salvage this by using the belt stretch factor and using it to resize a copy.

helipaddy

October 16, 2023, 11:07am

3

I have never calibrated however I couldn’t see that working as it would make both the tenons and the mortises wider

WillAdams

October 16, 2023, 12:10pm

4

I will try making an STL from the files I posted and see what happened.

Probably you could fix this with a chisel and some patient fitting.

gdon_2003

October 16, 2023, 8:04pm

5

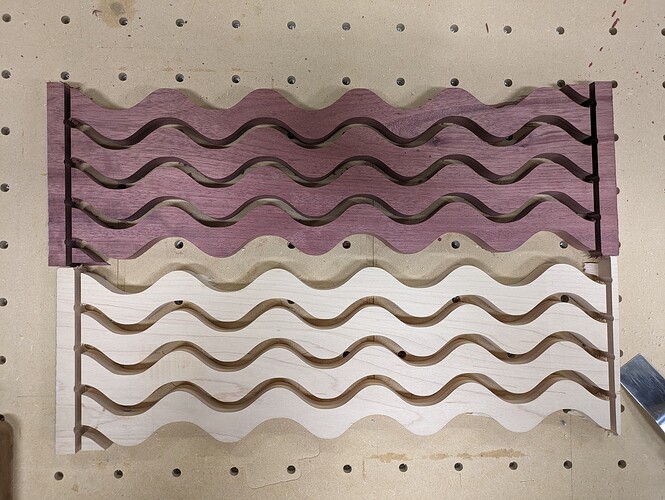

I feel your pain. I was in a hurry to make a board with alternating purple heart and maple. This was to make a bowl from a board. I never moved the graphic together to see if it was symmetrical. The result was a failure. However I poured epoxy to fill the gaps so all effort was not wasted.

WillAdams

October 19, 2023, 1:44am

6

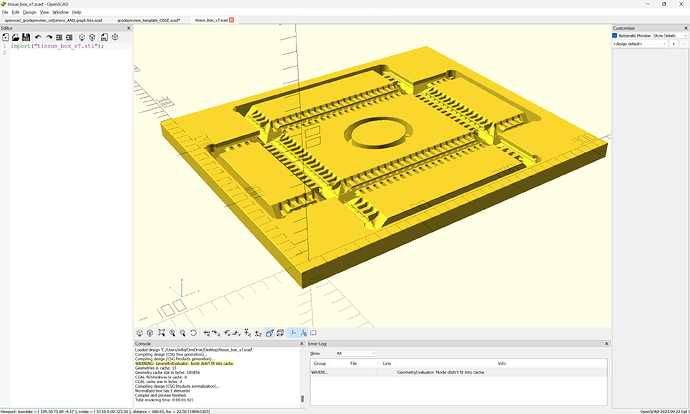

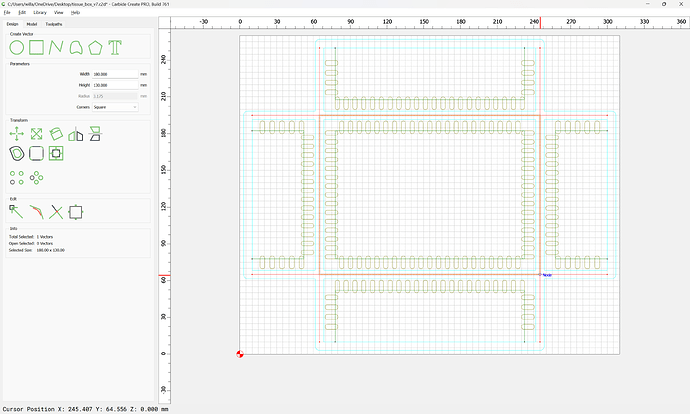

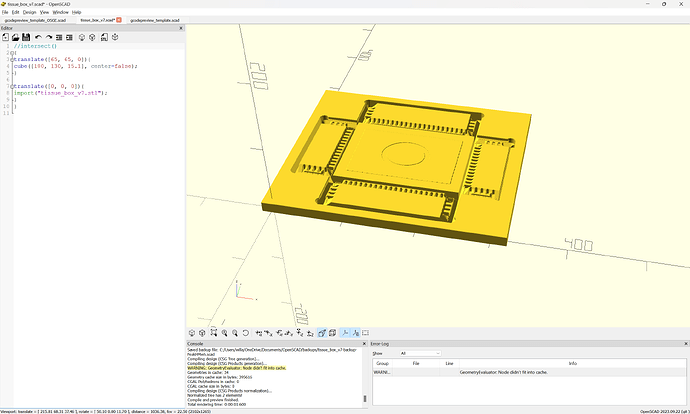

Exported the G-code from the file and used it to make an STL which was then imported into OpenSCAD:

Checking the dimensions we need:

and things must be offset by:

and adjusted by Stock Thickness:

Unfortunately, even after repairing the STL, I wasn’t able to get intersection to work with this file:

Going to go try something else…

1 Like

system

November 18, 2023, 1:44am

7

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.