I’m told that switching oil to grease or vice versa requires cleaning out the previous lubricant from the bearing blocks, so the first rule would appear to be, keep using whichever the machine shipped with unless you’re prepared to properly clean the blocks out.

If you’re switching, avoid any of the greases containing ‘slippery’ particle additives such as graphite or Molybdenum Disulphide as these will make the balls slide on the rail instead of roll and destroy the blocks in relatively short order.

The simple rule for when to relubricate appears to be to wipe the rail dry with a cloth, run the axis back and forth, then wipe again to see that a film of oil or grease is deposited on the rail, when this stops happening, time to fill the blocks up again. This has the handy side effect of having you clean the accumulated chips and crud off the rails…

Somebody who knows a lot more than me pointed me at this document

Where an OEM of high quality linear bearings describes the lubrication options, including giving specific selections of greases and oils suitable for various applications.

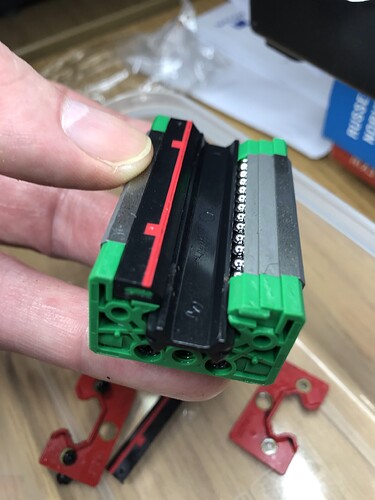

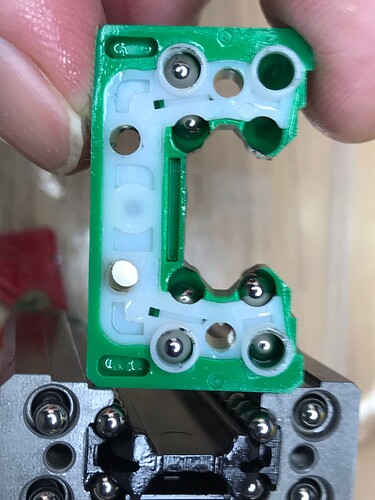

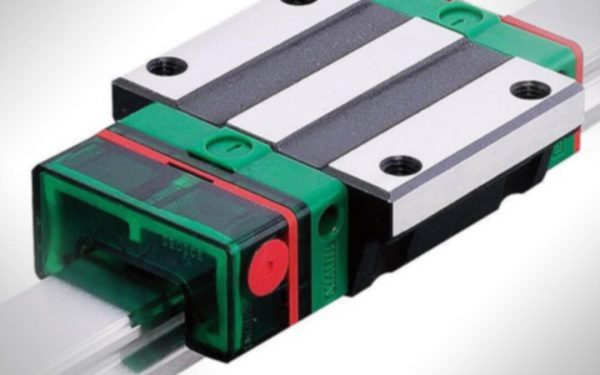

Looking at the lubrication quantities and relubrication intervals in the document, the blocks on the HDZ are closest to the HG series, I think the smaller blocks on the X and Y axes of the Pro machines are closer to MG series, but I don’t have one so I haven’t confirmed.

One thing that surprised me is the relubration interval graph (pg 11) which suggests that at the low load in this type of machine, the relubrication interval is in the many hundreds to 1,000 km of block travel. Most Shapeoko users are likely refreshing rather than replacing the lubricant when re-lubricating.

They describe the lubricant options as high viscosity grease, low viscosity grease and oil. Regarding oil they state:

“The relubrication intervals for oil lubrication are reduced to 50 % of the relubrication intervals for grease lubrication”, however, that is still hundreds of km.

On greases, as noted above, the document states

“Greases with solid particles such as graphite or MOS2 must not be used.”

On oils the doc says

“Lubricating oils offer the advantage of more even distribution and reach the contact surfaces more effectively. However, this also means that lubricating oils collect in the lower area of the product as a result of the force of gravity and thus more quickly cause soiling. For this reason, higher quantities of lubricant are required than with grease lubrication.”

Remember that this advice is given in the context of continuously operating industrial machines where the users expect many 1,000s of km of bearing operating life between replacements, 1,000km is 1.1 billion lengths of an XXL axis… These bearings are basically on holiday in a small gantry router

In my experience, I’m happy to fairly regularly fill the blocks up with some Mobil Vactra (I bought a litre on eBay) and flush the old stuff out well before it ages or the blocks run dry. I’ve mostly got the hang of stuffing a small syringe into the various lube ports on the rail blocks.

HTH

![]()