I’ve been trying to wrap my head around this, I understand the concept but there is one part of this that I don’t understand. I am also trying to translate these instructions into Carbide Create, just need some hand holding.

Here’s how I think this would work with Carbide Create.

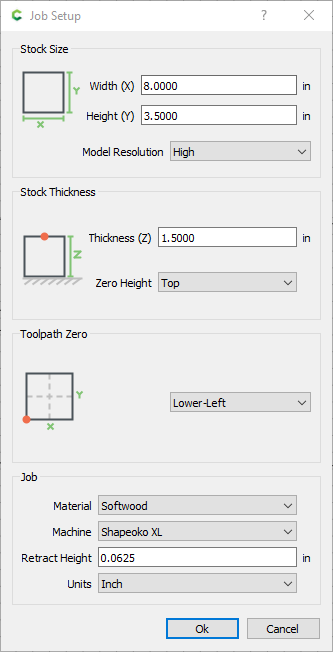

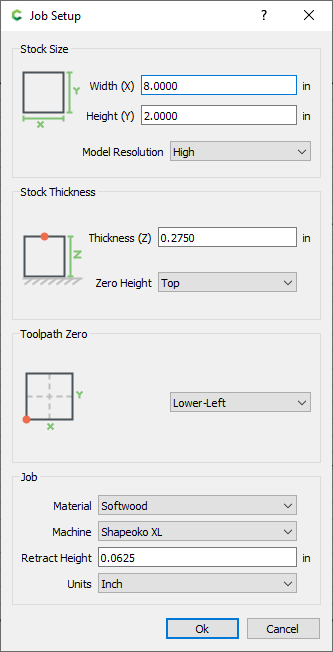

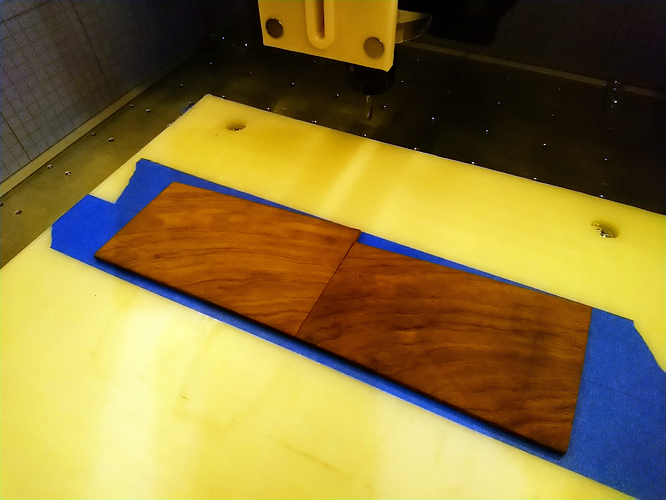

First the pocket (because that is easier to understand). I’m going to practice on some 2x4 lumber, so I setup the stock for the pocket.

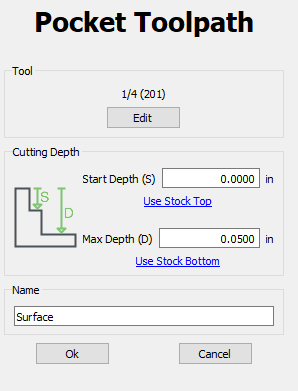

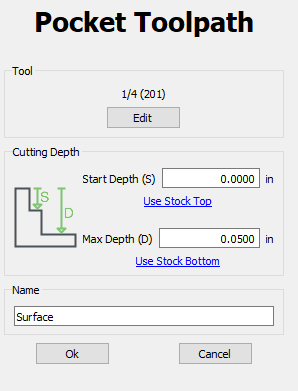

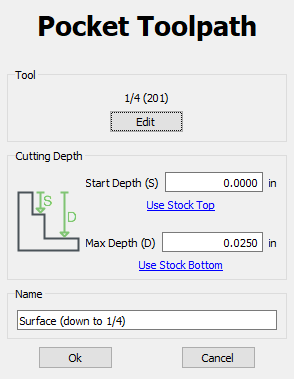

For toolpaths, I first surface off .05 inches to give me a flat starting point.

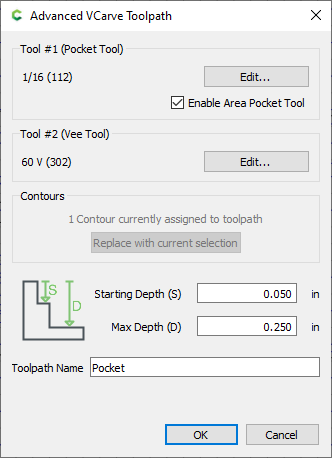

And then I create the pocket, which has a starting depth of .05 (because of the previous surfacing) and a max depth of .25 resulting in an actual pocket that is .2 inches deep (right?) because .25 - .05 = .20

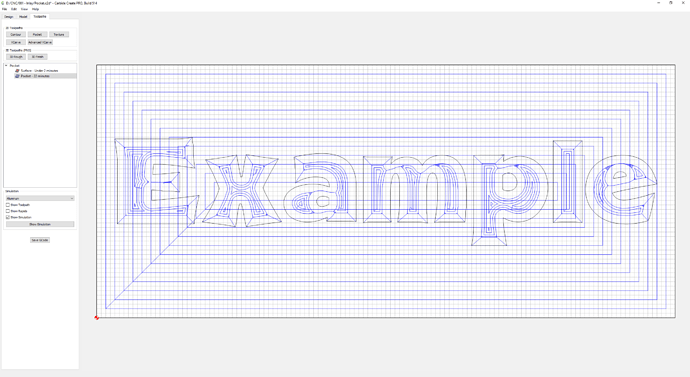

Resulting in…

Up to this point I think I have understood the process and correctly translated it into Carbide Create. But now the more difficult part, the plug.

Let’s pretend that I measured the wood I want to use for the plug (aka inlay) at 8 inch width, 2 inch height and .275 inch thick.

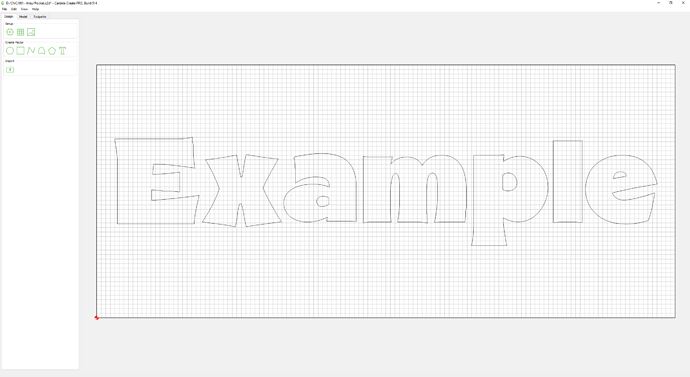

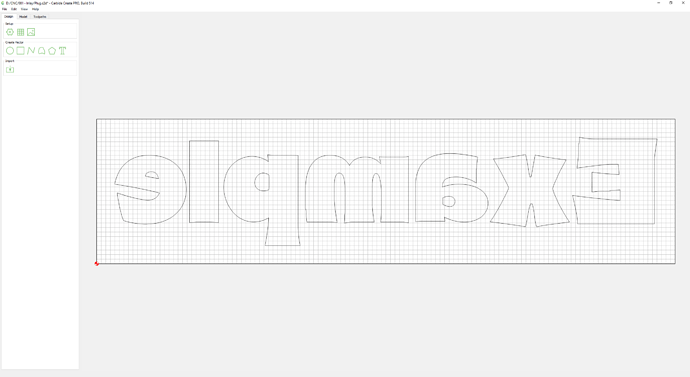

And after mirror flipping the inlay my Carbide Create design looks like this.

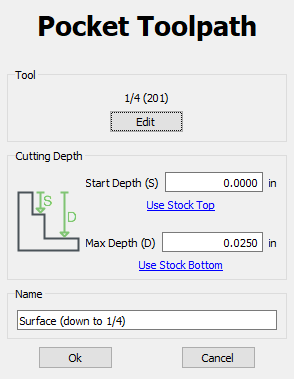

To make sure I start with flat stock, I surface the stock down to .25 inch. So a pocket toolpath with a start depth of 0.0 and an max depth of 0.025

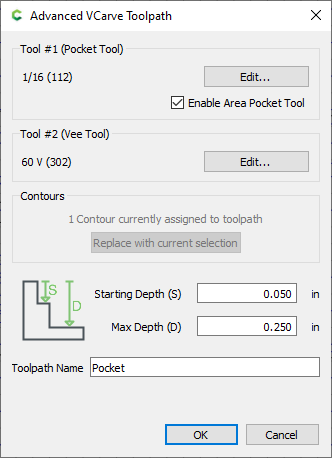

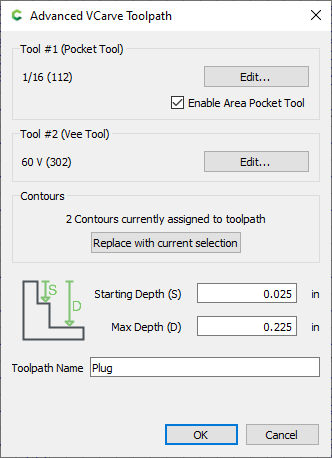

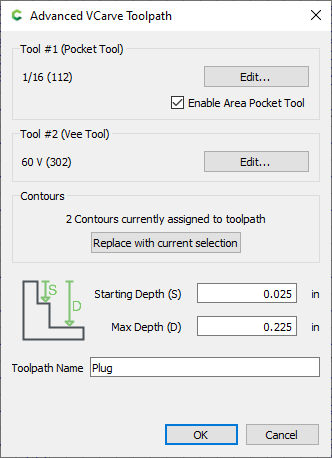

Everything makes since to me up to this point, here is where it falls apart in my mind. I know the next step is to make the inverse plug that will fit into the pocket. The pocket is .2 inches deep, so what my mind wants to do is perform a VCarve that starts at .025 (what is now the top of the stock) and go down an additional .2 inches, so a max depth of .225… but this is clearly wrong.

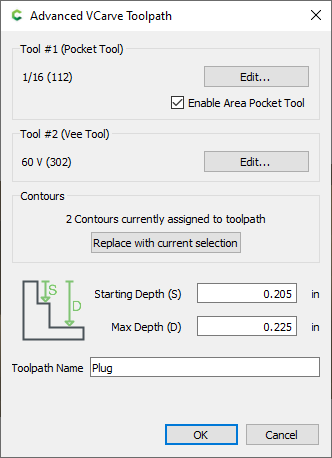

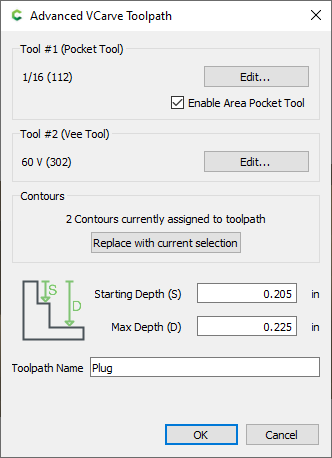

… the tutorials I found online that use VCarve use different terms “start depth” and “flat depth”. If I ignore the different terms and just follow their examples I calculate my start depth by taking the amount I surfaced off and add .18. For my example that would be .205 (.025 + .18), with a flat depth (aka max depth) of the amount I surfaced off and add .20 (.225 = .025 + .20).

This looks like it would work, but I don’t understand. If I’m asking Carbide Create to V Carve from .205 to .225 wouldn’t the plug be .02 inches tall? But somehow this makes it .18 tall?

The only way my brain can make since of this is if an inverse V Carve effectively processes everything upside down. I’m asking it to start (aka start depth) .205 inches up from the bottom of the stock? But go down to .225 from the top of the stock?

Help me understand, thanks.

I have hundreds of maple trees and use the broken ones for firewood. I have yet to find an olive tree. While maple is a very good and strong wood, it has a tendency of contracting and expanding significantly with the seasons. In the winter it contracts when the inside humidity level in very low then expand in the summer when the humidity level is very high. I find that yellow birch is almost as good from a strength perspective but easier to work with but a bit more stable.

I have hundreds of maple trees and use the broken ones for firewood. I have yet to find an olive tree. While maple is a very good and strong wood, it has a tendency of contracting and expanding significantly with the seasons. In the winter it contracts when the inside humidity level in very low then expand in the summer when the humidity level is very high. I find that yellow birch is almost as good from a strength perspective but easier to work with but a bit more stable.