Hello everyone:

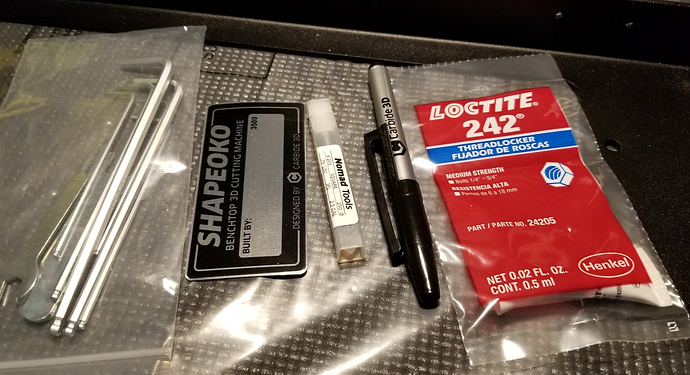

I am new to the forum and new to the Carbide 3D family. Last week I ordered a Shapeoko 3 with a few accessories and upgrades; HDZ and clamps.

I was really looking forward to ordering a metal threaded base plate but it will have to wait on that until they are in stock or make my own (anyone?).

I little bit of background, back in 2013 I bought my first CNC machine (CNC Mogul). I used it a few times but sold it shortly after. My lack of CNC knowledge caused some frustrations and my ignorance did not help much with this particular machine. Needless to say I need something a little sturdier for what I wanted to accomplish and with a bigger bed. After a few months late 2013 I order a CNC Router parts Pro with a table of 24X48. This was the perfect size for what I needed to do and over the years I kept up with their upgrades and updated the machine to their latest spec that included linear rails.

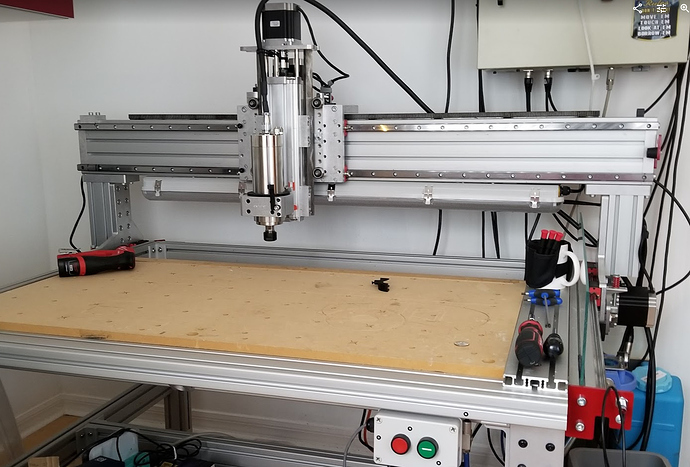

My CNCRP Pro / Avid, was running on UCCNC, with Nema34 motors and a water cooler spindle as you can see from the photo below. It was a beautiful machine and very capable. It cut MDF, plastics and Alum. quite well, accurately and reliably.

This was my fist real machine, and I learned a ton with it. I made some great parts with it.

I went from vectric, to Rhinocam and now to Fusion.

All these years I lived in an apartment, an then a townhouse with a single car garage with no space for this monster. With it being so larger, dust containment was always a challenge despite having a dust deputy and vacuum. I think all CNC machines need to have an enclosure not only to contain the mess but also for safety. The machine was kept and operated indoors and dust containment kept me form using it as much as I wanted to. The thought cleaning up really put me off.

I have now moved to a new house where I have a two car garage where I can have a CNC machine. However during all this time, I realized that aside from the one project that made me upgrade, I was only using a small part of the table 20x20 max. So this machine size was too big for my needs.

So I sold the machine . I took it apart and sent it off to its new owner (I think it is still in transit).

I looked at a CNC/Avid benchtop pro, as a replacement. Ball screws and linear rails (OMG) but again the size of the machine albeit having a 24x24 table would occupy a large area in my garage.

I also have a confession, I have always had a crush on the SHAPEOKO. (I looked at other brands but in the end SO3 has many advantages, coming for a larger machine).

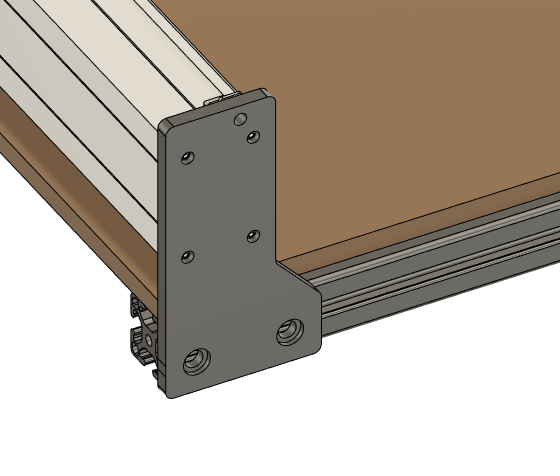

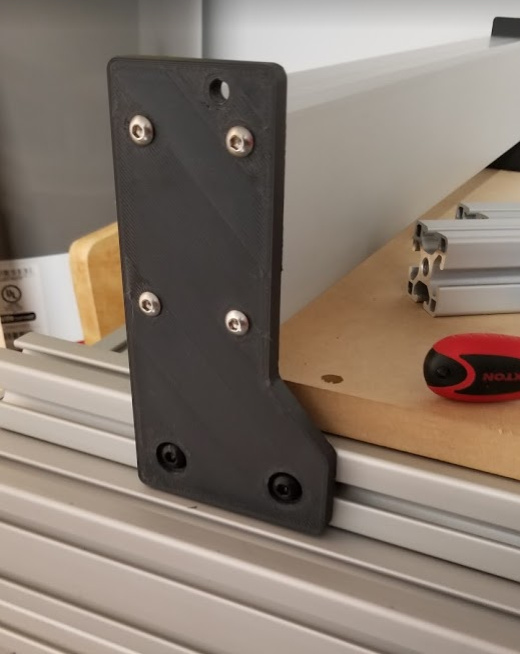

While I wait for my SO3 to arrive (should be here this week) I decided to re-purpose some extrusion I had left over and build a bench for it. This bench is made from 8020 Alum extrusion and features leveling casters so that I can move the machine around if needed. The wheel levelers ratchet which is great. The SO3 will fit right on top and in the near future I will add an enclosure to this table. (I want my garage clean).

At this time, I need to finish or come up with a few more lateral braces and a top, but as it is this table it sturdy and will be a great foundation for any machine and certainly for my SO3.

As you can see, I have a fog mister and a dust cyclone (not shown). but I am still far away from being done. I want to add compressed air and a nice flexible hose overhead (any recommendations of the hose)

(maybe one day I will get a snapon monster) but for now my Husky and Milwaukee brand will do.

(maybe one day I will get a snapon monster) but for now my Husky and Milwaukee brand will do. .

.