Hmm, it wouldn’t surprise me but I don’t think so. The German phrase they use is “Verwindungssteifigkeit”, where “steifigkeit” = “stiffness” and “Verwindung” = “torsion”.

Also, I wonder why they include that number for the hobbyist D-series but not the higher M and Q series? (Note: you said “formerly” but for the D-series, the numbers are still advertised on the main product page)

I wish I knew what I know now when I bought the Nomad though. For the $3k of the Nomad, I could have had a larger machine, with a real spindle, linear rails, ballscrews, more powerful motors, more detailed specifications and a better ecosystem. Or, if I’m reading their specs right, I could just have had a machine about as wobbly as the Nomad for about half the price.

Anyhow, I have the Nomad now so that’s what I’ll stick with.

In other news, I emailed Mechatron to ask about a spindle. I was thinking to start on the Z-axis but then realized that I really need to know which spindle I’ll be using so I know what the spindle mount will look like. Now I’m pretty sure I’ll be going with the HFP-6508-30. It’s more ~1k€ instead of ~0.5k€ like the cheaper spindle but the extra low runout and extra 6k RPM seems worth it, especially if I’ll be using my now huge collection of 3mm endmills.

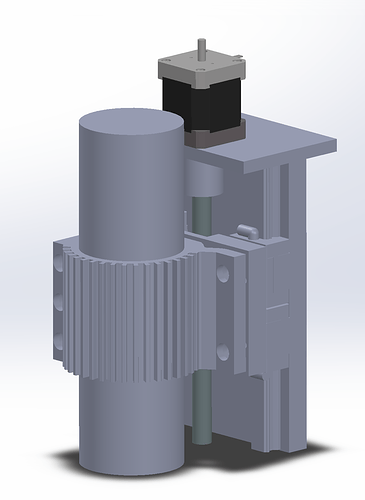

So that leaves me with a 65mm spindle for which I’ll be using a spindle holder with a 120mm x 80mm mounting flange. That doesn’t leave a lot of space for bearing blocks so I’m wondering whether I should increase the height of the mounting plate (e.g. make it 120mm x 120mm) or just use two longer bearing blocks (TBI Motion TRS15VN) . Using single blocks does subject them to moment but they’re rated for 15000 kg-mm on all axes. Assuming they’re ~50mm from the spindle and my maths isn’t crazy, that’s fine though, as it leaves me with 300kg of force. So I’m inclined to go for a simple 120x90mm adapter plate for the spindle, that just bolts the spindle holder to the bearing blocks.

One question I’m yet to answer there: should I just tap holes in the adapter plate or should I use nuts or inserts? I’ve heard that Aluminium threads aren’t the most reliable things in the world.

I also looked at ballscrews and couplings.

If I go for 12mm ballscrews, I get 26kgf/µm of rigidity and a load rating of 900kgf, which seems plenty and I like that they’re compact, so I think I’ll go with the SFU01204-4 nuts and screws.

Speaking of ballscrews, @Vince.Fab, what size did you end up going with? Did you have any issues fitting the ballscrew nuts onto the X and Y axis carriages? I haven’t been able to get a good look at the hole that the AB nuts fit into yet. Will a 24mm diameter nut fit in there?

And finally, I looked at steppers. I’m thinking about whether I need to upgrade to NEMA23 for Z since it has to lift a 2.4kg spindle now and keep it still while it’s under the axial load from cutting.

Anywho, I think that’s enough of my day’s thoughts written down for now. Hopefully tomorrow Mechatron will reply and I’ll finally buy the spindle and move forward with the Z-axis design.