I am attempting to resolve an issue that has been persistent for a few months. After reading a few different threads and attempting several fixes, I decided it was best to check with the community.

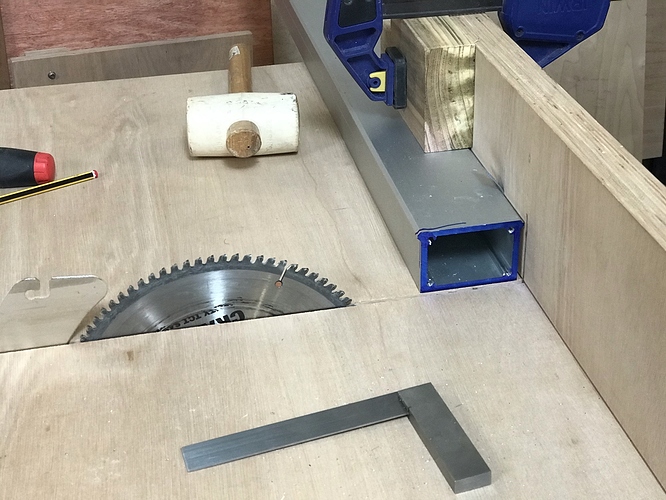

Ultimately I can cut a small (4"x6") square, and it comes out perfectly square. I have checked this with a few squares. However, if I cut a larger square, (20"x30") square it comes out non square. To resolve this I have ensured my machine is square from corner, to corner per Winston’s videos. I have also ensured the wasteboard is leveled to the machine. The V-Wheels are properly secure, and I am using HDZ eccentric nuts with a little thread locker. My last attempt was to calibration my belts (steel core), I did this following the following thread: Measuring belt tension, squaring and calibration

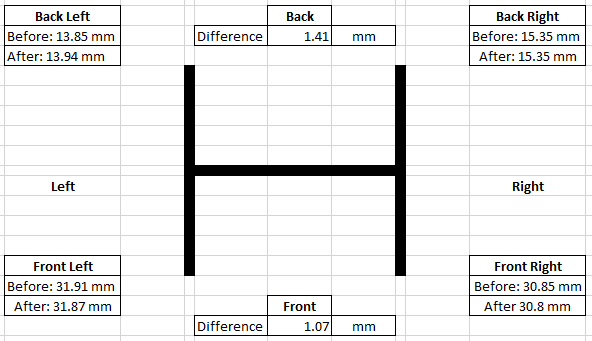

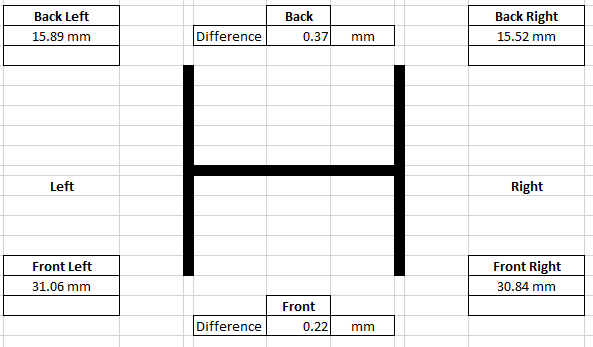

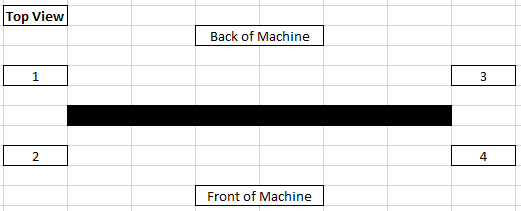

I calibrated both of my Y-Belts to 123 Hz, however the distance from the Y-Rails to the front and back plates are not close like mentioned in the above thread. For example on the front left of the machine, I get a distance of 13.94 mm and the front right is 15.35 mm, a difference of 1.41 mm. To ensure my machine is square, I pulled the gantry, all the way to the front and both Y-Plates touch the front plates of the machine.

I may be answering my own question, but would you adjust the belts to different frequencies to ensure the distance between the front plates to the Y-Plates or equal? Or within a reasonable difference? This is the only thing I can think to try next, I just have been frustrated with this and want to ensure I am not missing anything. Below is some other information that may help.

- I have tried adaptive cuts, with a finishing contour pass.

- Material: MDF

- Amana 46170

- 17000 RPM (Makita)

- 41 in/min

- HDZ

- Dust Extraction (Suck-it)

- DOC: 1-2mm

Let me know if you need any other information