Update ( )

)

After lunch and a lot of internal debate, I’ve decided that it’s not a great idea to make a fidget toy out of leaded brass. Probably should have considered that from the beginning

What’s next

That gives me the opportunity to practice a skill I’m not great at though: Pivoting!

Ok, so I’ve lost half a day but I’ve gained a design for later when I’ve got the appropriate material. Not terrible but it certainly limits my options for the rest of the day.

Namely, I’ve got to come up with something that:

- Uses the material I have on hand

- Does not require a ton of material removal

- Is not terribly boring

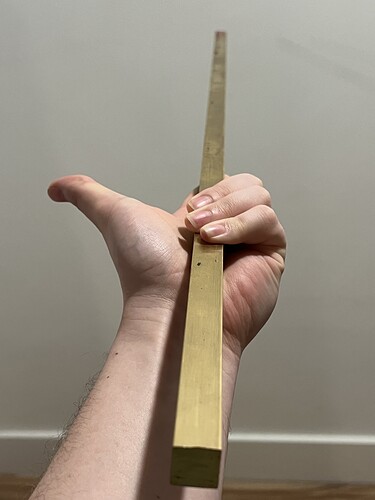

Material on hand is going to be a 3’ long section of 3/4" lead free brass (464)

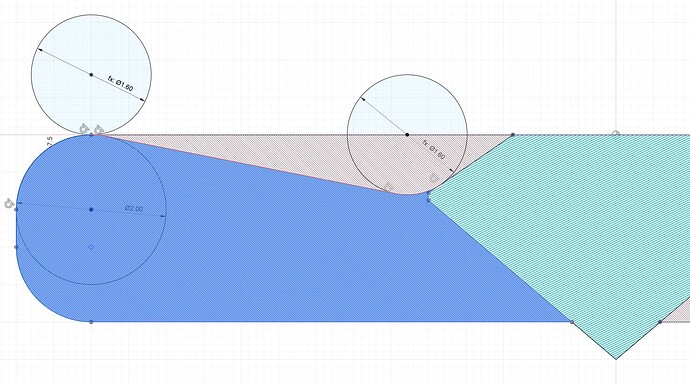

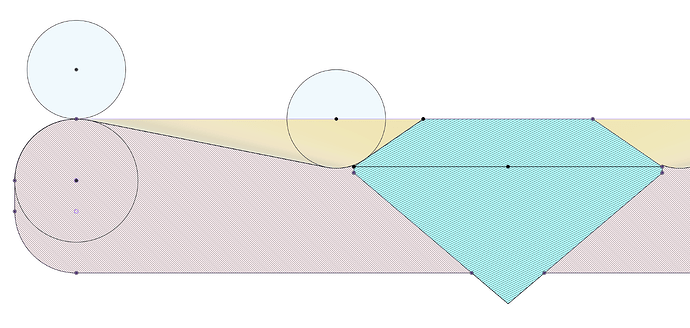

I could try and make the same design with this brass bar stock and just tombstone the disks. Basically cut the features and cut below depth by the width of a bandsaw blade…part off, clean up the bottom side and boom, tokens for days…

But I’ve never done that kind of thing so I’m not sure how well it would turn out.

Instead I am going to go back to an old favorite that is very much on theme for the party.

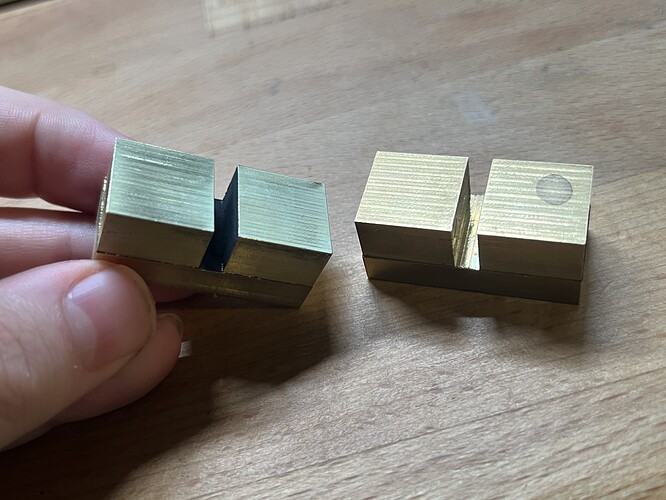

A plain ol standard D6 (AKA 15mm cube)

This would require very little material removal, only about .5mm from all sides, and it’s dead simple to do work holding so there are some time savings there as well.

The cube approach also gives me a lot of optionality. Knocking out the cubes will be straightforward so it’s just a matter of adding features after that point.

I’ve got my self centering vise which means I never have to re-zero after the first cube setup. This means if I have time, I can throw on some music and v-bit the numbers or pips into each face. I would also take the opportunity to try chamfering the edges and truncating the corners. (Folks who have been around may remember this idea from a long past due post  )

)

It wouldn’t be terribly fun to index so many times but life isn’t always fun

If I really run out of time, I can very quickly laser engrave the numbers. This always feels a bit cheap to me but in my experience, most folks think laser engraved numbers are still super cool so

Finally, I can make some variations of the dice. High polish brass, antiqued brass black, nickel plating, copper plating, all very quick and easy. Folks can choose their preference as they arrive and the late folks can barter with the other guests if they really want a specific aesthetic

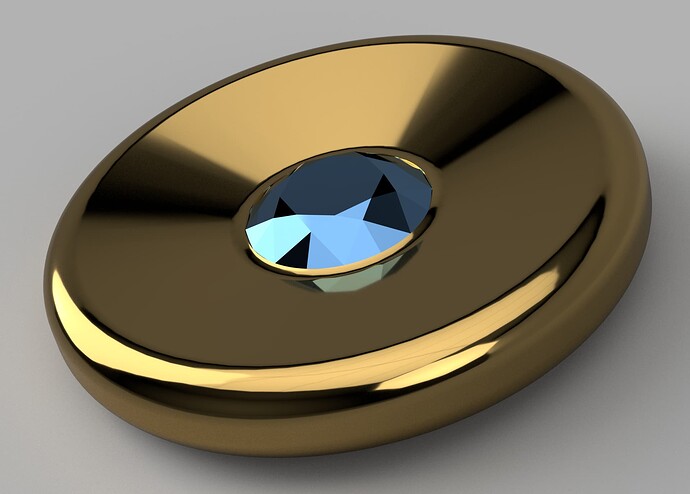

Finally finally, I can make some very fancy ones for the mini game prizes. With gems for the pips and precious metal plating (The jeweler will plate same day if I get them to him before 9am tomorrow morning. Done by 3pm, plenty of time to pick up the wife’s friend flying in from California…it’s gonna be a packed 24 hours.)

I won’t bother with all of the little in-between bits for now but I’ll post photos of the major updates along the way. Wish me luck

![]()

![]()