WillAdams

(William Adams (Carbide 3D))

8

You are cutting a slot just as narrow as the tool to a depth greater than the cutting flute length:

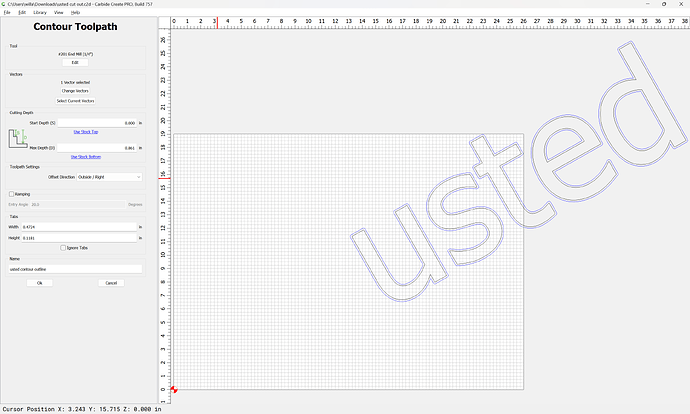

(I don’t have the font you used, but that shows the toolpath setting)

Where possible avoid slotting and add geometry and cut as a pocket

and/or

and consider leaving a roughing clearance and taking a finishing pass.

See:

2 Likes