One which has a cutting flute length equal to or greater than the thickness of the stock — pretty much any tool should work.

Big thing is the toolpaths — if cutting out, rather than just cutting a slot:

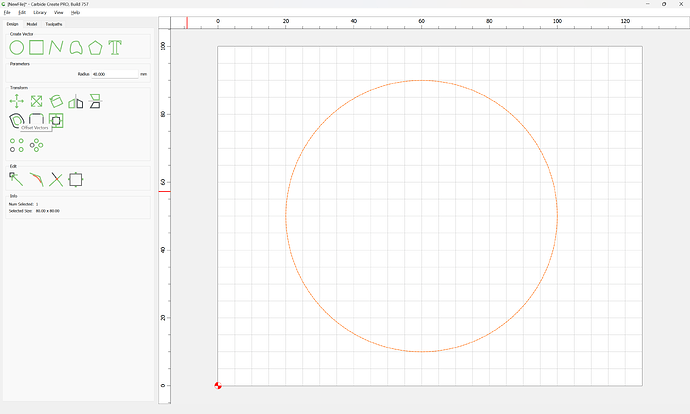

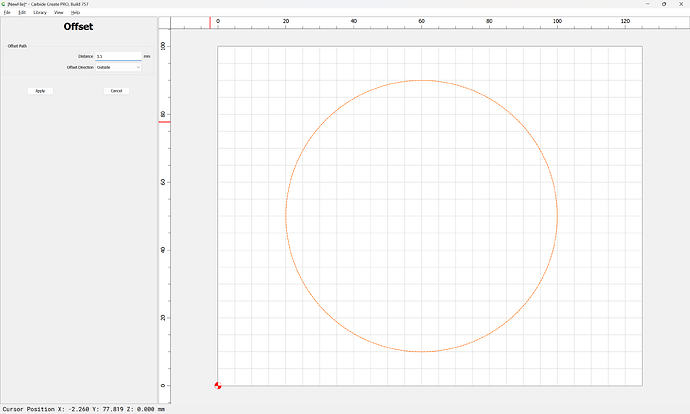

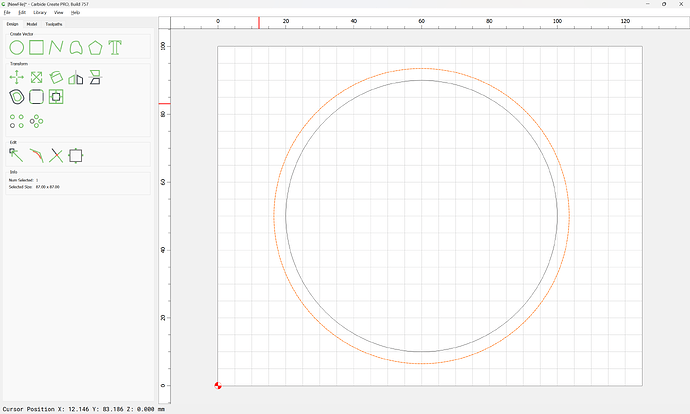

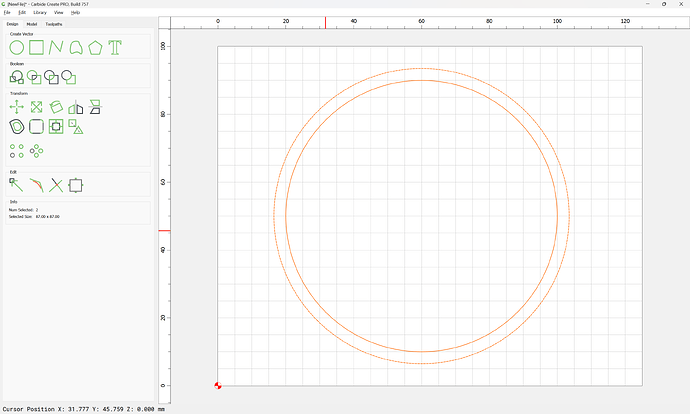

Offset to the outside by endmill diameter plus 10% or so:

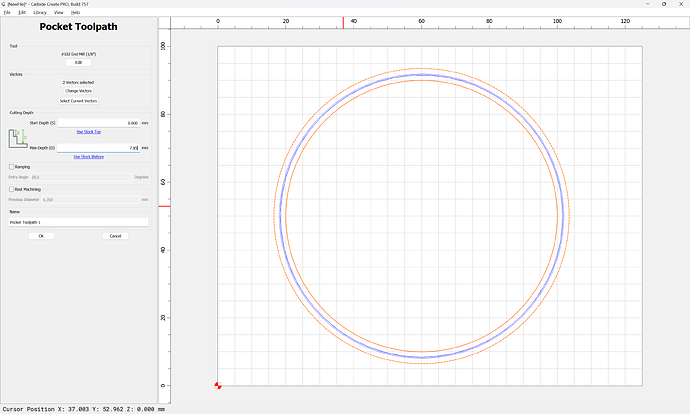

Then cut as a pocket:

down to tab height or the penultimate pass:

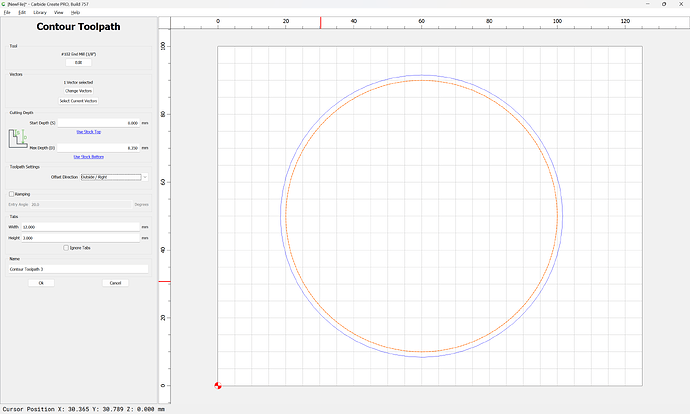

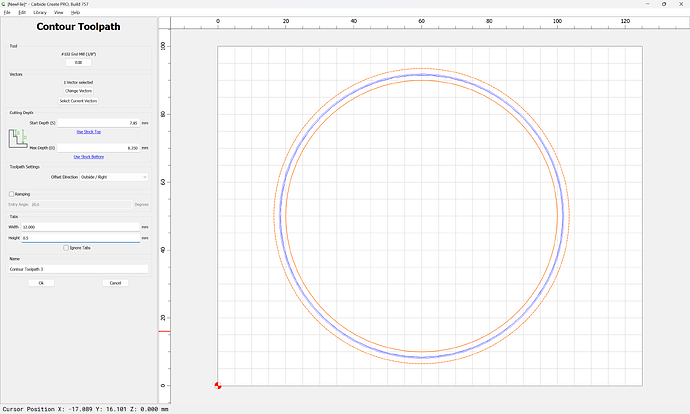

then move the contour down to below the pocket and start cutting at the bottom of the pocket:

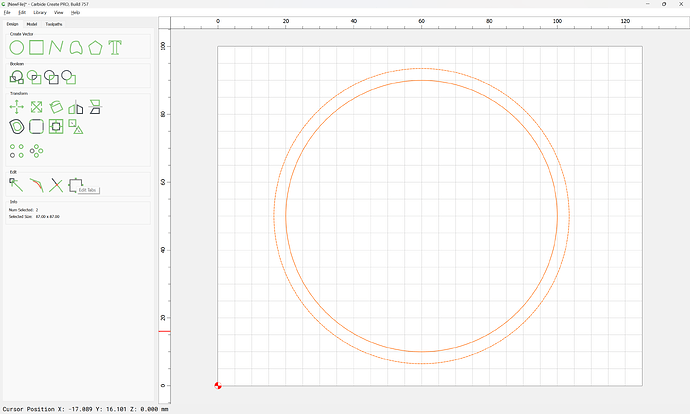

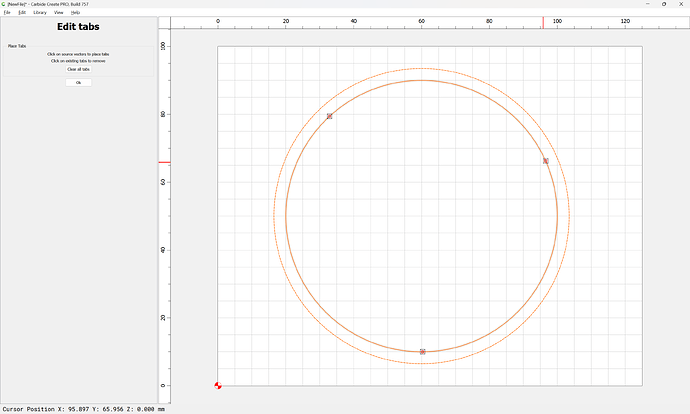

and go back and add tabs:

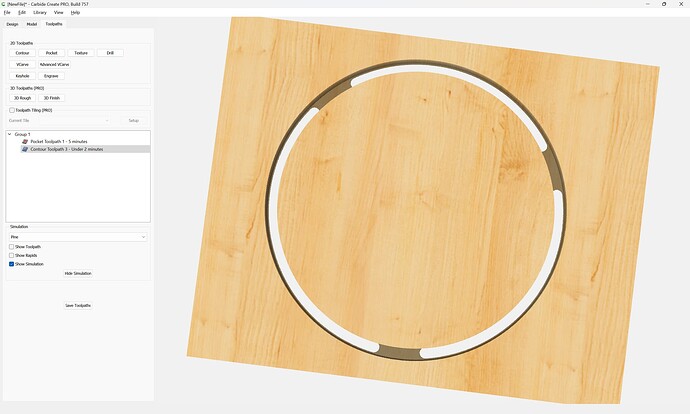

which previews as: