Chaotica

September 10, 2023, 7:11pm

1

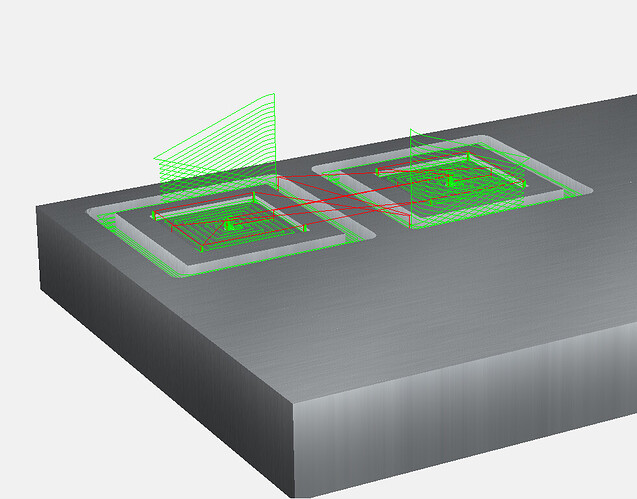

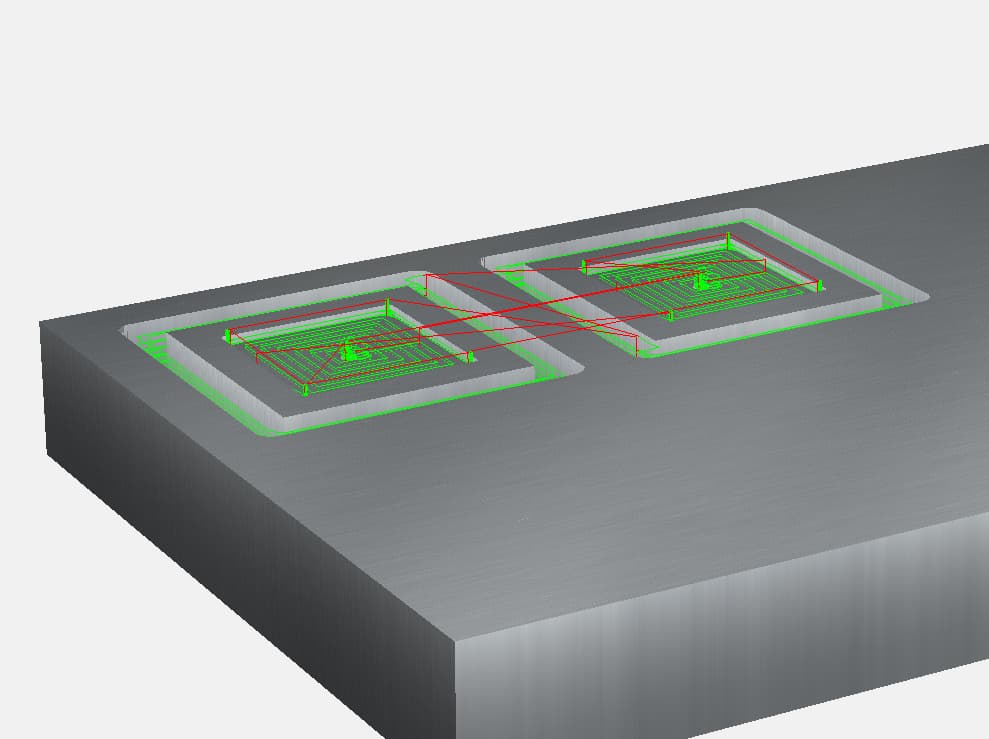

Was prototyping a small design when I discovered a weird thing about Pocket toolpaths with ramping enabled - with Z-zero set for bottom of stock the toolpath wants to start way above the stock thickness(possibly twice the height of stock thickness?).

Changing the Z-zero to top of stock & the toolpath starts at the Retract Height above stock thickness as expected.

Seems like a stock height 2x mulitplier got into the code for what Z the path ramping starts at which greatly increases the cutting path length/time.

2 Likes

You’re not the first one to notice this issue.

I have tried using the ramping feature many times but it does something strange that I do not know how to correct.

When I turn on ramping it will raise the spindle/router about 1" above the workpiece after every pass/layer it cuts. So if I am cutting out a bunch of pockets that takes say 10 passes/layers per pocket, the spindle will raise up and back down 10 times for each pocket. A perfect example of how annoying this can be. I just ran a job today that had 96 pockets. That is a crazy amount o…

So I’ll fully admit that this might be a total user issue as I’m just getting back to the software after letting things sit for a while due to life getting in the way, but I’m seeing strange toolpathing on a rest machining operation.

I am pocketing out a bunch of hexagons from a 1/2" thick piece of material, first with a 1/4" bit and then ideally using an 1/8" rest machine operation, but when I run the gcode generation it produces an enormously long toolpath (over 1400 minutes). Upon closer ins…

I’ve been told it’s on their radar, but I’d still file a bug report to bring more attention to it.

system

October 10, 2023, 7:11pm

3

This topic was automatically closed after 30 days. New replies are no longer allowed.