I’m confused. After I build a design and try to safe the file it indicates I am

only saving 66% of the file. Why doesn’t it save 100% of the design?

In what context are you seeing this 66%?

Could you post a screengrab? Upload a(n incompleat) file?

As the green graph showing the amount of file saved it stops at 66%. Not sure how to give you a screen shot. New to CNC and Carbide3D Pro. Will, we are close by, I’m in Lebanon, Pa. Also an Air Force vet…

If you’re on a recent version of Windows, launch the Snipping Tool:

and use it — you can then paste the screen grab into a message here.

If not, let us know the specifics of the computer you are using and we’ll look into how to do this.

I suspect that what is happening is it flashes up the progress display on saving, then when it gets to 66% finishes the save, and since the save is finished, terminates the animation — can you open the .c2d file after saving? Is anything missing? Are you creating toolpaths? Do they preview as expected? Can you save the file after the 3D preview?

When CC v7 first came out saving a file would stall at 66% and sometimes finish and sometimes not. In later versions they fixed that problem. So what version of CC are you on. Suggest you download and install the latest version of CC to see if that help.

Please check that your disk is not full or something like that. Those kinds of things can sneak up on you. Another thing you can do if using Windows is hit Ctrl Alt delete and pick task manager. In the options you can make it stop on top. When saving monitor for memory and disk activity to see if maybe you are maxing out. If like disk useage is 100% eventually that will subside but if Windows is doing an update that may take a long time to subside. The task manager may help narrow down what is causing your bottle neck. Sure there is something similar to task manager if running a Mac.

My last laptop had a regular spinning disk. That started having issues that would cause long boot up and long delays when running applications. I eventually bought a new laptop but bought a solid state drive and installed it in the old laptop, reloaded Windows and gave it to my grand daughter. She loved it.

I just bought Carbide Pro last week. The version is 001-1. I would assume it’s the latest version.

There is the current stable version:

which is build 778, and a beta v8:

which is build 805

Thank You. I will download when I return home.

That was the version I have. I think the complete file is saved because when I

bring it back everything is there.

I’d like to forward the file to you to see what I am doing wrong.

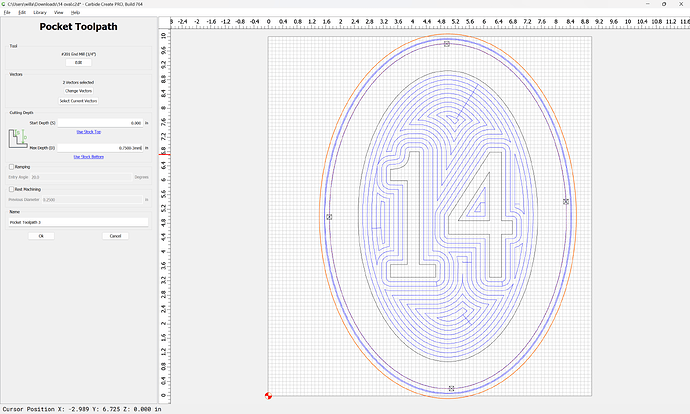

The area that I hace to pocket is set to .125 in.

When I run the program the bit cuts all the way down to the bottom of the stock.

What am I doing wrong?

14 oval.c2d (120 KB)

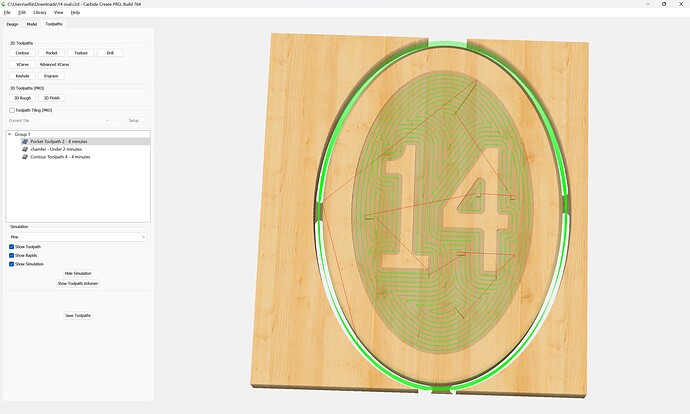

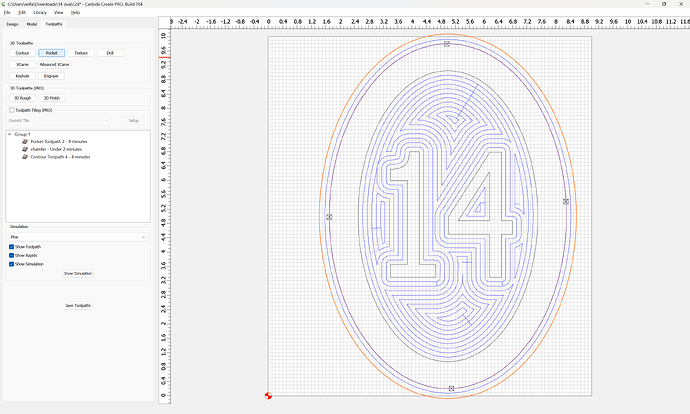

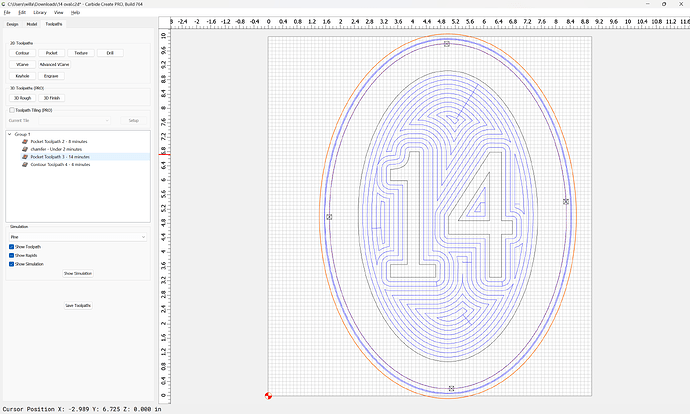

The 3D preview seems fine:

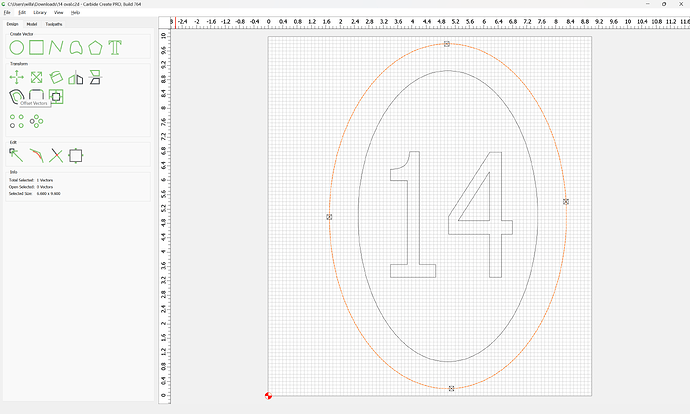

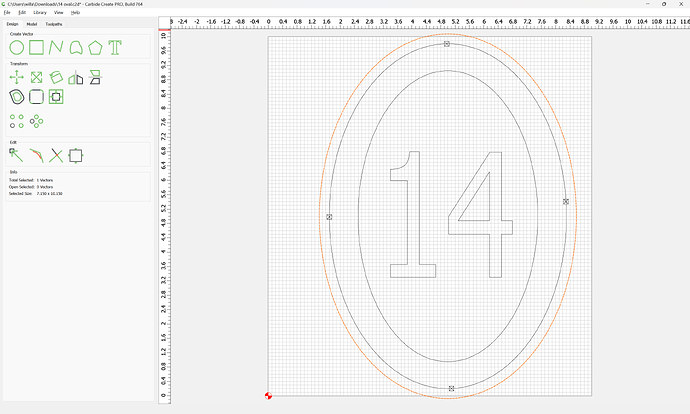

My recommendation would be to select the outer geometry:

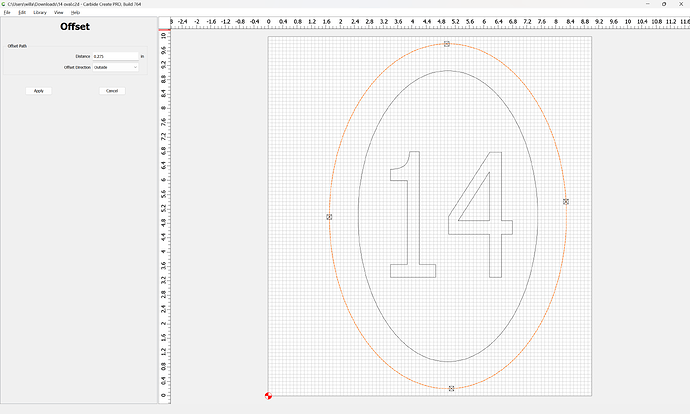

and offset it to the outside by endmill diameter plus 10%:

Apply:

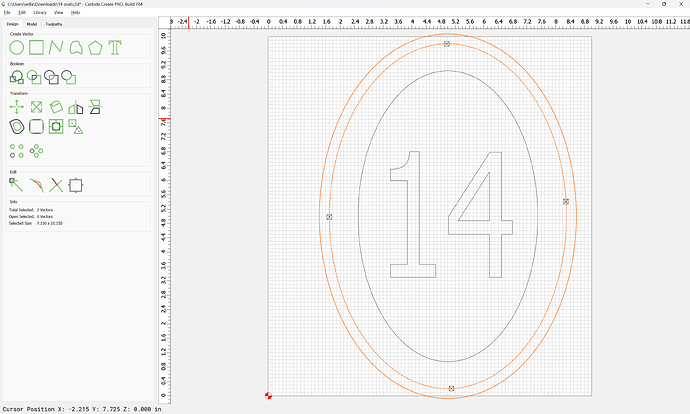

Select the offset and original:

and then cut as a Pocket down to tab height:

Moving it up above the contour:

Also, if you start w/ the #301 you can maybe save a toolchange:

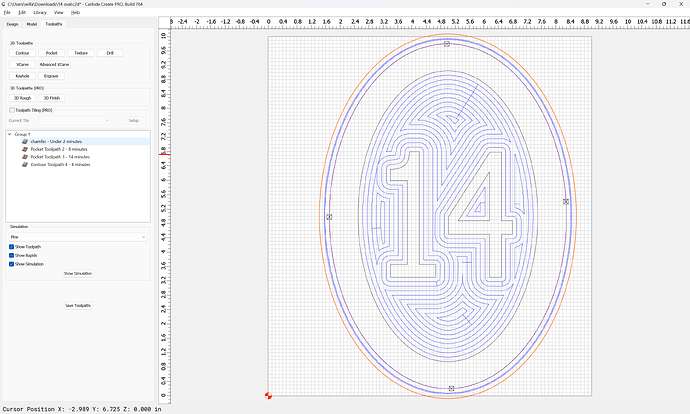

(toolpaths are re-arranged by click-hold-dragging)

which then previews as:

An optional improvement would be to offset the pocket twice, once a very small distance so as to leave a roughing clearance. Where possible avoid slotting and add geometry and cut as a pocket

and/or

and consider leaving a roughing clearance and taking a finishing pass.

Sure is nice to hear from someone who knows what they are talking about.

I think you misunderstood my problem.

The first think my machine tries to do is cut out the pocket around the numbers.

That’s when it goes all the way down to the bottom of my stock instead of the

.125 depth I have set.

That’s the problem I am having.

I am using the Bitsetter.

That is presumably caused by a disconnect in how you have set up the file:

https://carbide3d.com/hub/courses/create/job-setup/

and how you are setting zero relative to the stock:

https://carbide3d.com/hub/courses/running-shapeoko/movements-zeroing/

If you continue to have difficulties, let us know step-by-step how you are securing your stock and setting zero relative to it and managing all tool changes, and send the file you are loading into Carbide Motion if it’s different from the above and post photos showing:

- the machine at the zero relative to the stock (or a specified offset from that position)

- the specific difficulty you are having in the cut/its current state

Will Adams, I really appreciate all your help. I am following all the setup procedures for setting the zero on my machine. still having problem with my pocket cut ging into my material further than the .125 in. setting I have in create. I know you are located in Pa. and close to me. Could I give you a call to discuss my problem? I am located in Lebanon, Pa.

I followed all the setup on the youtube sites you sent me.

If you are able to talk to me I will give you my number so others do not bother you.

I think it would be better if you checked in with the folks at support:

If that doesn’t work out, I’m sending you a PM and we’ll see what can be worked out.

That said, if you will let us know step-by-step:

- what you did

- what you expected

- what actually happened (including images of what you are seeing on screen)

we should be able to work through this with you here.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.