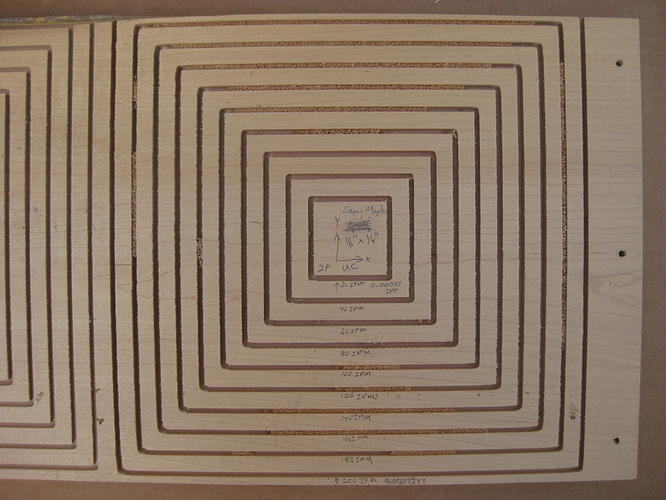

One of the first things I did on the shop’s XXL with a Dewalt DWP611 Router was cut some slots in sugar maple with an 1/8" 2 flute Yonico 31210-SC upcut endmill at “27000 RPM” with feeds stepped up from 20 IPM to 200 IPM as shown below. (The camera caused the apparent curvature of the cuts.) Assuming the router has adequate power, going progressively deeper with that diameter cutter could help determine the machine’s force limitations without breaking anything. Using larger diameter cutters could determine the router’s power limitation without breaking anything.

Monitoring/Logging power while doing this would help determine if chipload and/or grain direction has an impact on K-Factor(s?) for that material and endmill.

It looks like @Hooby’s nice wood hardness spreadsheet somehow fell out of the SFPF Workbook somewhere along the line. I’ll put it back in the next update.