I see no reason why not. I have a standard-sized SO3 which uses flip machining without issues. Workholding is key… can you hold the workpiece in the same place every time you place it on the baseboard? You could make the workpiece an exact dimension to butt up to a straight edge/right angle you have placed. Alternatively, a jig that will hold your workpiece and that you fix into place on the baseboard will assist you to machine in the same place. Belt tension is a useful thing to address. I tune my belts with a vibrating guitar tuner attached to the machine endposts until they all read C3 [130.8 Hz.] The Hz value is derived from the informative work by @LiamN (Measuring belt tension, squaring and calibration)

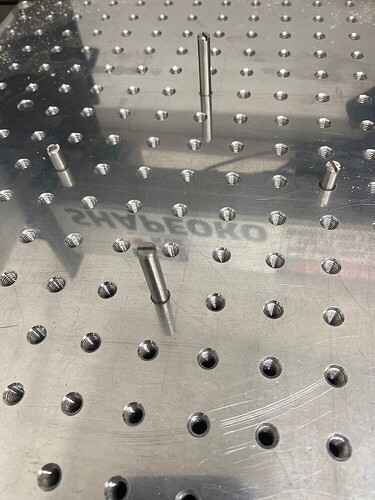

Remember that many end mills will often only be nominally sized. This fact may be responsible for you not getting the accuracy you desire. I attach a couple of images of my baseboard with a workpiece that I can orient in any direction (North, East, West and South on both sides). Consider this the minimum accuracy you must achieve if you are to successfully mill on both sides. Add in belts that may be pulling unevenly, with uneven tension issues, along with end mills that are not the size you thought they were. Add inaccurate and insecure workpiece holding, aided and abetted by baseboard-to-gantry inaccuracies, then you can see that there is a lot to consider before undertaking two-sided milling.