I created a file that is a letter 24x24 inches, when cutting the first 2 toolpaths cut ok, seems like the router struggles randomly within the cutting of the project. I checked for software updates and found I was using an older version of Motion so I updated it. I recalibrated my material thickness to ensure it was accurate and it is. Not sure why the machine keeps getting stuck in the middle of my project. Thoughts on what I can look at or adjust?

Describe (STUCK)

What is sticking.

Is the machine connection failing?

Are any of the belts lose and slipping in the same location?

What are you cutting. thickness and seeds and speeds.

Post your file may also help.

Pictures/video could help.

Anthony

Hi Anthony

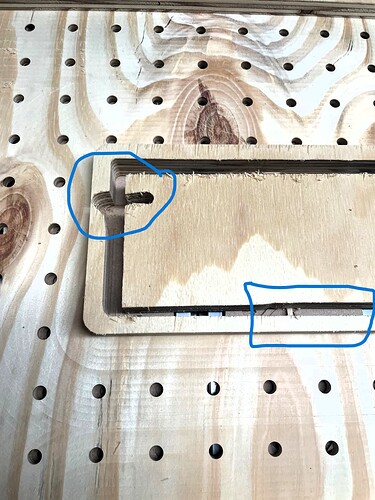

As the machine is cutting it sounds like its struggling then begins to get hung up in the wood and the project begins to try and lift off the table but I have it screwed down and it is trying to move but it cant then I hit stop. It did this multiple times (3). I had to restart the entire toolpath each time. You can see in the pictures the 3 times

B in NBS 14 In Letters.c2d (244 KB)

,

No the machine connection didn’t fail

No the belts feel to be the right tension ( each of the 3 locations where the machine got hung up is different places)

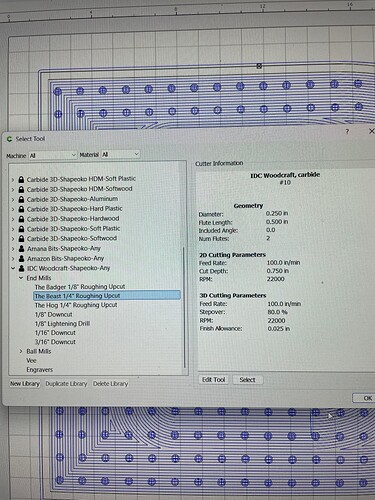

Hardwood Plywood, .6800 thick, Here is an image of the bits speeds and feeds img 2030

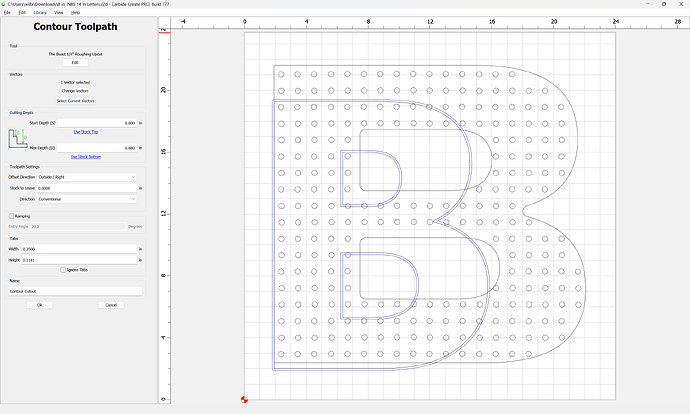

You are cutting a slot to a depth more than twice that of the tool diameter:

Where possible avoid slotting and add geometry and cut as a pocket

and/or

and consider leaving a roughing clearance and taking a finishing pass.

I agree with Will your depth of cut is not only more than twice the diameter of the bit it is also deeper than the cutting length of the bit. This can cause chip buildup and allow your bit to bind and do crazy things.

Add the geometry as Will described and reduce your depth of cut to .080, change the feed rate to .080 or less and plunge rate to .060. This will slow things down and not stress on the tool, machine or material.

As you are cutting and if everything looks good after the first pass you can always override the feed by 10% and as much as 200%. this is something I do on nearly every machining I do.

Double check all of your belts I also see some deflection in the tool path the almost a rectangle in the picture. This can be caused by belts or pulleys slipping. or as aggressive as this cut is by too much stress.from a deep cut.

The somewhat circled section makes me think about missed steps. These can be caused by too much load on the machine and material or poor electrical connections on the motors.

I would also a some tabs to help keep the inter sections in place you can place them on the straight sections and it will be easy to clean up.

Hope this helps

Anthony

Thanks Will and Anthony,

I will be making the adjustments and will double check the belts again.

Thanks John

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.