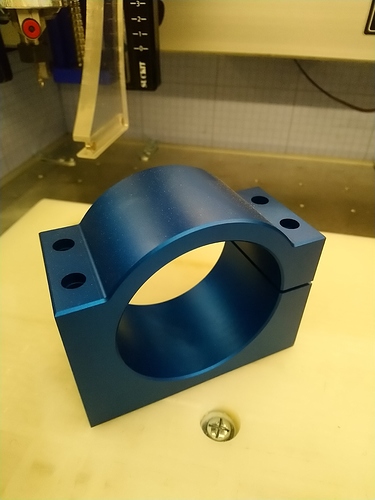

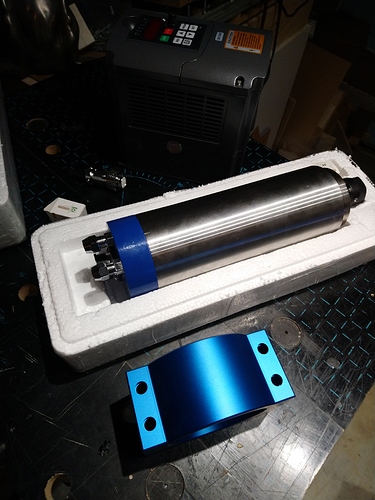

Allright, it’s been months since I bought a 80mm spindle mount from @Luke, and the trick I played on myself worked: I have now had enough of having it sit there unused, so I need to buy a spindle now (and no, I have no pressing reasons to do this upgrade, I just fancy the quiet and automatic RPM control)

I have re-read many spindle-upgrade threads here, but it did not tell me what to watch out for when trying to pick a specific offer in the sea of chinesium products on ebay/amazon/aliexpress.

Does it boil down to “you cannot trust any of these specs anyway, just roll a dice, pick one and cross your fingers” ?

From your experience are there any “reputable” brands or brands that I should avoid at all cost ?

Is there any way to tell if the advertised bearings and runout value are not completely imaginary ?

I’d rather buy a higher quality 1.5kW model (which is plenty enough for me) than an average 2.2kW one, but I really cannot tell them apart right now.

Any hints and tips would be appreciated, thanks !