My standard S3 has all of it’s cables flopping around out back, and the XXL has some as well, I noticed the new Pro has a 3rd Cable routing chain which I am anxious to check out.

I am about to add air blast and water cooled spindles. Do you run your air/water up with the vac hose or off the side of the machine in a chain or what?

Has anyone done this? Can you give me some ideas to design a working system?

Thank you!

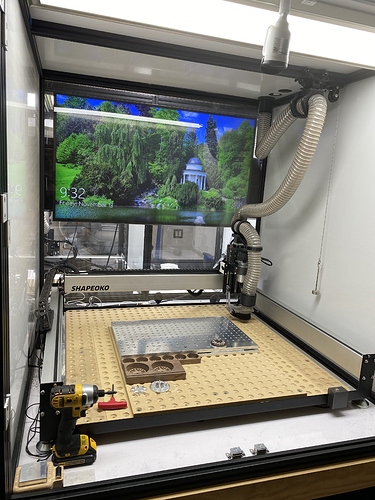

I built an enclosure, and one of the (in hindsight) best things about it is that I added a little loop in the center of the ceiling of it. That loop I use to hang the vacuum hose but also the water cooling/VFD cable off of. It being in the center means that it only needs a bit of slop in the part on end end of the hoses/etc to reach all the corners.

So don’t just think “down into a chain” but also ponder “up”

My current setup on my XXL has a extensive hose pulley system that has a perfect balance, I would prefer to route my air/coolant hoses through a separate possible 3 chain system?

wow that’s fancy. hats off.

Mine is pretty prosaic — just the stock drag chains and a bunch of zip ties, but it works well, and in particular, stowing the excess lengths of wiring in the drag chain seems to work well.

Nice Will! Thank you that gives me some ideas. Similar to my race car plug wire looms, something like this could be milled with the Shapeoko and would be good for mounting hoses.

Still want a 3rd cable chain design for the XXL and also for the S3 or something similar.

I suppose 3D printed would be better to lower the weight.

That is an interesting idea. Could the hose brackets be printed to connect to the drag chain? I have mine zip-tied.

I am sure I can easily design and print something like that but I worry about other aspects.

Not sure about a secure method of attachment, I want to minimize the force needed for the steppers to power the folding of hoses. I am sure it all adds up to greater resistance for precise positioning.

I found a thin flexable 3/8" air hose, but it gets stiff when pressurized.

Upgrading to water cooled spindles takes away the air blast that substantially helps clear chips when milling so I need something! How much air pressure is needed for chip evacuation? I never dealt with it before.

At what point do you need to upgrade steppers with a heavy HDZ, a upgraded spindle, hoses, a Suckit with aluminum brackets etc…

Don’t want to upgrade my equipment into being unusable!

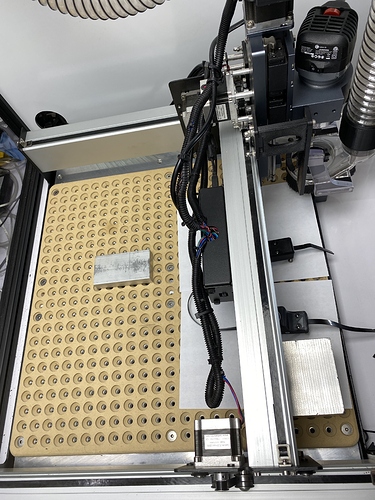

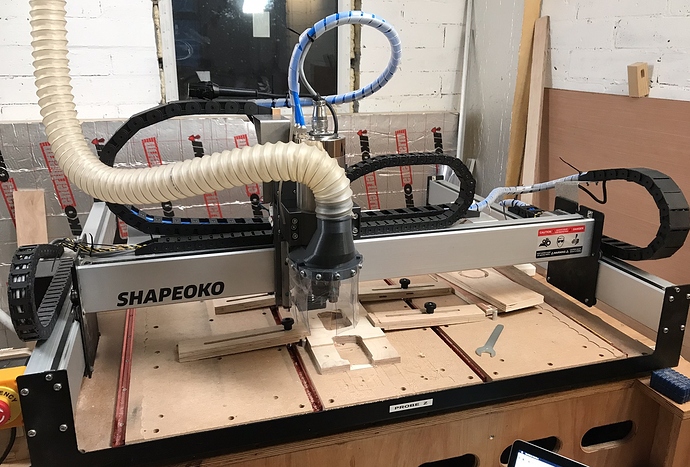

Separate chains like the Shapeoko Pro are good for keeping router / spindle power cable noise away from the signalling cabling on the Shapeoko, here’s my current XXL untidy installation with £10 drag chain from eBay.

Yes thank you very much that is beyond what I have been pondering with an additional chain. Can you share specs on the chain length and size please? Did you drill into the rail? Very nice job! Can easily print my own chains!

Here is the thread that shows what I did to control my wiring.

I thought the drag chain I bought was overkill, but I now have my VFD wiring, water lines, stepper motor wires, a grounding wire and an additional air blast line inside it.

MadHatter wow, going into possible overload here, that is amazing. Very detailed work. Would you care to sell a set of these brackets? I assume the chain is store bought, I recognize the yellow inserts.

They’re 1 meter R38 18x37mm, I chose this size as big enough to have lots of space for coolant pipes and extra stuff. The spiral wrap going partway into the drag chains and cable tied to the mounts provides some extra strain relief and mitigates cable wear at the entry / exit to the drag chain.

I’d use MadHatter’s mounts though, mine were just cut and bent to fit without any real design.

I did drill and tap the X and Y beams to mount the extra support brackets, double sided tape is not a valid way to anchor drag chains…

I used the stepper mount bolts on the Y plate for one of the chain anchors.

Thank you Liam, I will be incorporating the 4th chain into my builds. Excellent design.

Do you have a spindle or a router?

Currently I have 3 S3’s with 3 carbide 3d routers, one is getting a 1.5 kw, one is getting a 2.2 and I am not there yet for a spindle on the 3rd. They are all being upgraded to 80/20 rail frames with 3/4" Aluminum caps. They all are getting linear rails and Dan Story’s rail kits which I have all 3 sets already. All 3 are getting plumbed into a Lightobject 1600 watt chiller.

OK,

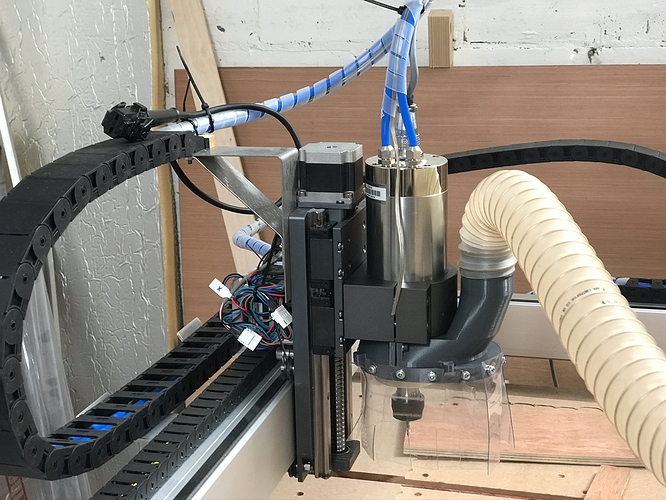

You may want to do a Z drag chain as well then, I’m doing that on my rails upgrade. I’ve got a prototype of the spindle end of it on the machine and all the bracketry for the other end as soon as I get the rails on. The spindle coolant hoses and wiring are quite heavy and don’t like repeated flexing at stress points very much. The spiral wrap is OK as a start but I can do better.

I’m presently figuring out whether to try to route the extraction hose through brackets on the Z carriage and if so where.