Well I guess maybe this is turning out a bit like a junior high school dance, where we’re all shy about being the first one out there dancing. I get it. Well, maybe if I go out there and start dancing, others will join in?

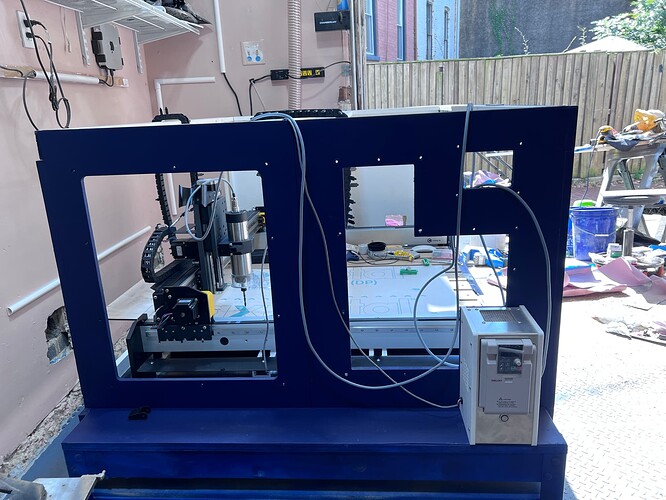

This enclosure cabinet was the first thing I constructed with parts cut on the shapeoko, which was a fun learning challenge. I made it as big as I could, fitting stock onto the shapeoko pro bed that barely fit the width. I love 90% of it, and the other 10% I can live with.

I wish the top could have been about 2” taller. I’ve bonked my head a few times when loading the machine. I’m used to it now, but early on… ugh, every day.

Server-rack switch-box works great. I was worried about capacity but it’s never failed me, nor have I accidentally ever bumped a switch. Highly recommend this if you’re looking for a multi-switch solution and don’t want to screw around with a bunch of wiring. I think it was only like 50 bucks, and has been a pleasure to work with.

I love this setup, everything I need is nearby, and I have a good spot for my computer and cnc related tools. The drawers are about 40” wide and 24” deep. Huge and fit a ton of stuff. All my cnc stuff is in there, plus all my sanding stuff, jigs, etc

I would love to finish things more but this is a workshop and I don’t want to get too precious about the condition of it. It’s sturdy and does the job

I bought these foam panels for soundproofing areas of the box, but they were ugly so I didn’t use them. They do work GREAT as router but storage.

I could get better sound reduction from this if it were lined the inside with foam or carpet, but it’s quiet enough already, and I’d rather see the wood.

Another part of my shop - Workbench top is doubled-up 3-1/2 x16 glulams, bolted together with threaded rod, and planed flat. Could park a truck on it. It’s nice

My shop is my favorite place to hang out when I’m not busy, and I’m always working on it. I’ve had workshops for 20+ years, but adding a shapeoko to my shop has opened up a world of possibilities and inspiration… kinda like finding a musical instrument that you like to play. Thank you folks at Carbide 3D for making this machine available and affordable.

I originally posted about the enclosure here: A “Soundproof” Shapeoko Pro XXL Enclosure.

Reading back, following up on my design goals: I was going for soundproof above all. I would say it’a succeeded at that, but not by the goals I had set. And “Soundproof” was never a target but 30-40db reduction was.

I use a free app to measure the sound levels, so who knows how accurate, but my normal quiet room noise bumps between 35db and 40db. . Router and vac on with from a couple feet away with the doors open is about 88db. With the doors closed on both enclosures, it’s about 65 and very pleasant to work around. Not my target, but I’m happy. You can’t hear it in the next room, and I can run it at midnight.

Temperature of the vac compartment has never been an issue. I vent it with a couple of enclosure fans from ac infinity. One from the bottom, one from the side. It has a digital readout and a temp probe. It gets a little bit warmer in there but never more than a couple degrees above the room, even running for hours.

Hope you enjoyed this tour!

Now that I’ve shown you mine, won’t you show me yours?