Cant you just calibrate your stepper moters?

No. (meaning it wouldn’t help). Maybe this will help you understand:

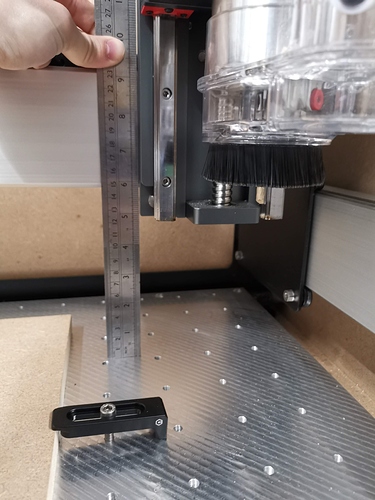

So thinking that @RichCournoyer had beaten me I got my measure out…

Now the XL and the standard have different cross straps, but my XL has a 12mm machined baseboard…

I have 4" and allot of change.

On an XL or XXL and even with a standard baseboard you would have over 4.5 inches between the Z and the base plate.

If you put your baseboard (I’m glad there’s a new name for it) under your end plates, you’d gain that thickness back.

Unfair test…S3 to S3 would be better…LOL.

Did you make those black parts in the Shapeoko? love it!

FWIW @luke I for one would be a buyer at a reasonable price. $100-ish and perhaps more.

RMW

The New Z riser plates? Yup. Back in the day I was a Tool and Die maker, and that never leaves. I make MANY tools and machines on the Shapeoko.

That is great. I would like to stalk to you offline. I just ordered a SO3. I am a former AVID CNC machine user / ower. Would you be open to ?

Go to my IG (JPL_Richard) and scroll back about 4 years…From Power Hack Saws, to Watches, to Vises, even using the Shapeoko as a Surface Grinder to finish grind a hardened Tool Maker’s Vise…you name it, I made it…While I hate wood, I did spend a year making a Museum Quality Antique reproduction Newport RI Chippendale Desk…Question, ask away.

Nice work! Did you do the program in Fusion? I know your using a custom controller, did you need to write your own post processor?

Yes I am using Fusion’s really crappy unwrap 4th axis feature to program the part…wow, is it bad…but it’s what I got (for now)…more bad news…there isn’t a GRBL 4-axis post processor. I found one in GitHub (4 years old) but it doesn’t work…so I am using the Tormach’s post and then hand editing my gcode to work in GRBL. Not a good reliable idea (I know), but after a week of searching, (and wanting to cut chips to test the system), it will work for now until I get with Autodesk and plead with them to help me make a GRBL 4 (or 5) axis post.

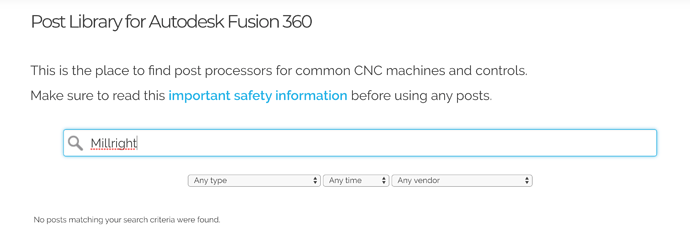

Rich, I don’t know if you will have any luck but, Millright CNC is using GRBL for their 4 axis machine.

Gary

Yeah, but …there are no Fusion posts or a Millright (in the public library) Their website says: (Grbl is what you’d want to select) <— Which is NOT a 4 axis. Do you know where they hide their 4-axis post?

Have you looked at the Avid CNC wrap y - A post or the wrap X- A post for fusion? Since things are slow at NASA I could probably bang out a modded post if I knew what the GRBL board is doing? Is the board the supergrbl board?

Yes. (Now 13 more letters to make Rob happy)

Have you seen/tried this one?

Is the board remapping Y to the B axis ? It’s like a blackhole of nothingness on programming for the SuperGerbil board, just digging through their firmware trying to make sense of what they have added to the base Grbl code.

Yes (as I said somewhere above) it does work.