Hi All it’s a saturday… sorry to bother you. I have set up my new G-Penny 1.5Kw spindle and Huanyang VFD… for testing wiring is all correct it seams … BUT when switched on my spindle goes from zero to eternity… at which point I stop it. The potentiometer has no control at all… have I missed something… or put in some wrong number on the VFD… can anyone help please?

Hi @tink07,

Can you post a snapshot of how you wired the control signals, as well as tell us how you setup your various VFD values ? My guess is it may not be properly configured to take the PWM signal into account as the RPM input, OR the mapping from input voltage to output voltage to the spindle is not right.

Hi Julien, Thank you for your help…again

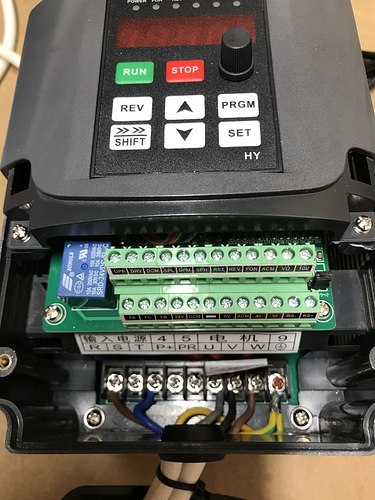

I have attached two images (yes I’m a photographer… and their not photos!!)

the spindleI checked inside and the colours on the tape (which I copied from an image… o its yours) are as…I took these as the numbers to the vfd… as the second photo

this was 1 = “U”. 2 = “V”. 3 = “W”

This when I switched on … gave me a anti clockwise spindle

I changed the to: 1 = “W”. 2 = “V”. 3 = “U”

this worked OK

The second problem is as I have written

I used your “Disclaimer” with the parameters… the only problems were:

PD142=10… I tried and it would only go to PD142=7… it will not go higher

PD143=02… I put PD142=4

&

PD144=3000 which I did… the VFD was … PD144=1400

I really appreciate your time in this… do you have a medal for all the help??

Allright, so you have not wired the PWM from the Shapeoko controller yet.

How did you set PD001 and PD002 ? Those two control whether the VFD takes the PWM signal as an input to activate the spindle (and at what speed). To figure out what is going on, you should probably go back to “operator” control (resetting PD001 and PD002 to 0), and then check if the spindle still starts on its own at power-on, or properly responds to the VFD buttons/dial.

Another lead: since you have a water-cooled spindle, there is no need for a minimal RPM value (which is the case on air-cooled spindle, or they can fry), can you double-check you set your PD011 to 0 ?

We’ll go from there.

In return I would like to ask you to clarify for me the semantic difference between a “photo”, a “picture”, a “snapshot”, an “image”, etc…not being a native English speaker I kind of use them interchangeably, so this will be the opportunity for me to learn about that !

PD001 and PD002 are set to “0”

PD011 is set on “0”

I have not wired to the controller yet as I am going to order a HDZ … Due to the weight of the spindle on the machine… and I cant find heavy duty spring to hold it.

Ha ha ha lol now…

Photo (short for photograph) was a term coined by Sir John Herschel and was based on light.

Picture is a visual representation of object, scene painting and drawing, this includes image, photo and snapshot

Snapshot is a term from a picture created from an image recorded on light sensative surface. This includes a negative or photographic paper

Me and image … sounds good

May I ask … in which part of the world are you… or where are you from?

If I knew as much about CNC as I do about photography I would be as good as you are at cnc.

I am proud that you can help people as you do…

I was the fist guy to sell a Commercial Digital Camera in the UK… it cost £10,000 and on had about 280,000 pixels

I’m sure I saw a thread a while ago where someone had the same issue, but I can’t seem to find it, so let’s continue digging in the meantime…

First, just to be sure we are on the same page, are you using the param values from that post, with only the modifications you mentioned above ? I know it’s tedious, but if you could make a note of every single param value you currently have, it would probably help to pinpoint the likely cause ?

If for some reason we cannot figure it out, another route could be to

- disconnect the spindle

- restore the VFD to factory settings (by setting PD013 to 08)

- re-adjusting the bare minimum parameters (spindle characteristics)

- reconnect the spindle and see if manual operation is ok or not.

- and then modify the params for external PWM control, later.

Thanks for the little lesson !

I’m French, and live near Paris.

Wow. I have fond memories of my very first digital camera, a Sony Mavica that stored pictures on FLOPPY DISKS! (the younger ones here probably don’t even know what a floppy disk is). And therefore I was carrying multiple boxes of floppy disks with me when traveling.

I will crack on and check everything

All the parameter values are set to “that post”

I have printed “yours” off and will photograph it and post for your perusal

Thank you again

Tink

Hey Keith,

I found that post I had a vague memory of:

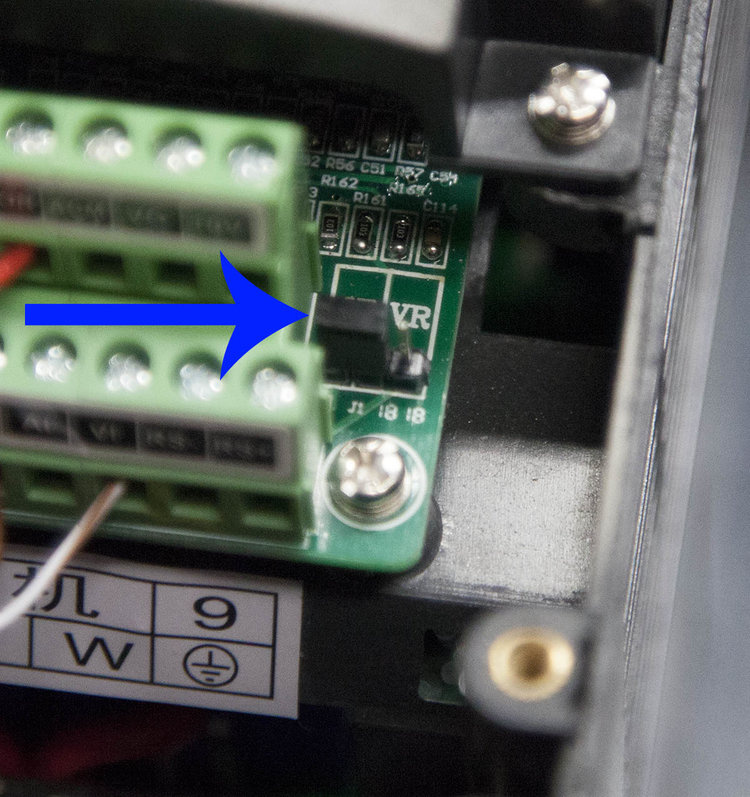

The “Setting the jumper on 1-2 keeps the spindle from starting on power up” part is what caught my eye, and may or may not be the problem you are having.

Me, I had to adjust this jumper to the “VI” position:

I would be a little surprised if this has any effect while PD001/PD002 are set to 0, but it will be required anyway when you connect the PWM, so might as well do it and see if it changes anything…

Hi Julien… I will check that … I have read your post thoroughly and printed it off… mainly as a guide and your experience ( I do understand Disclaimer though …ha ha ha )

I have made a little progress by changing frequency values!!!

PD003=50

PD004=50

PD005=50

it slowed spindle down on enter and stopped me panicking

- why are the values set at 400Hz on everything?

- why is PD144=3000?

Max on my spindle is 2400

- 400Hz is the max frequency to be used by the VFD to control the spindle. I bet it must be etched on your spindle body like this ?

Basically, the VFD will vary the frequency with which it feeds the coils in the spindle, to control its speed (hence the “Variable Frequency Drive” naming). 0 Hz will map to 0 RPM, and 400Hz will map to 24.000RPM. By setting PD003/4/5 to 50, you effectively have reduced RPM from 24000 to 6000, which is less scary but does not explain why the spindle starts on its own at power-up, so let’s sort that out first (and then you will need to change PD003/4/5 back to 400).

- PD144 is the rated max RPM of your spindle, but expressed in a weird unit of “RPMs if your spindle max frequency were 50Hz”. Since this spindle max rated frequency is 400Hz not 50, we must translate “24000RPM for a 400Hz spindle” to “XXX RPM for a 50Hz spindle”, so XXX = 24000 x 50/400 = 3000, hence why we set PD144 to 3000.

Now to inspect that jumper !

Jumper is set to VR

I have set the VFD to 400Hz

Personal view is the potentiometer os not working as it does nothing at all

The spindle just goes like a rocket… I switch it off at 18000.

(with the VFD turned off obviously) can you move that to the “VI” position (should be the two pins on the left, see image above), and report if it changes anything ?

No changes

its funny really the revs are showing in the display so thats normal!!

And the VFD ignores the STOP button and the potentiometer position, whereas PD001/002 are set to 0 ?

I’m at a loss then

no I switch it off using the red button on the VFD

it’s just the potentiometer does not work … if the pot is fully turned to the left I thought the spindle would go slow and as I turned it around it would go faster… I turn the pot and the spindle just keeps going

Re-reading the manual, the “main frequency” stored in PD003 appears to only be used when in “operator” (manual) mode, so you could set that to 0, which probably would leave the spindle idle upon power-up (I’ll dig if I can find something else about not waiting for the “Run” button in operator mode in the meantime…).

This could turn out to be a good enough workaround, because (says the manual), PD003 is ignored when the VFD is configured for external control (which it will be, once you set PD002 back to 1 after this is sorted out).

I’m with you on that… I did set PD003 = 50 and it stayed at a constant low speed.

when I get my HDZ i will configure the PD001 & PD002 to run from the control board on my XL

Until then it’s back to my Makita

Thank you for everything

You did not say where you are based??

Yeah so safety first, set PD003 to 0 in the meantime.

I did though ![]()

Thank you for the help… I’m in Staffordshire centre of the UK