It should be good to replace that. If you sent a picture, I’m sure they’ll get one out to you.

Thanks @robgrz fleming took care of it.

FYI @WillAdams @Julien

I have been seeing some intermittent missed steps in the x-axis culminating in a complete binding. I fortunately caught it on video (let me know if you want to see). The stepper wouldn’t turn the ball screw at all. I checked for detritus in the ballscrew and wipers and found nothing of consequence. I removed the stepper from the bearing mount, and the ball screw turned free by hand, and the stepper turned free by hand. Reassembled and tightened and saw the same behavior. Upon disassembly and inspection it seemed the bushing in the lovejoy coupling wasn’t fully seated and was binding axially when the stepper was tightened. I was able to flip the bushing and fully seat it, tighten everything back down and it seems to have fixed it. I also noticed one of the 4 stepper screws was cross threaded in the mount. I was able to clean the threads and reinstall.

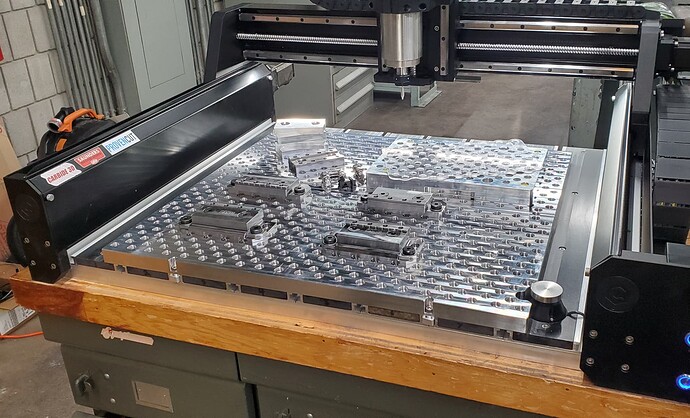

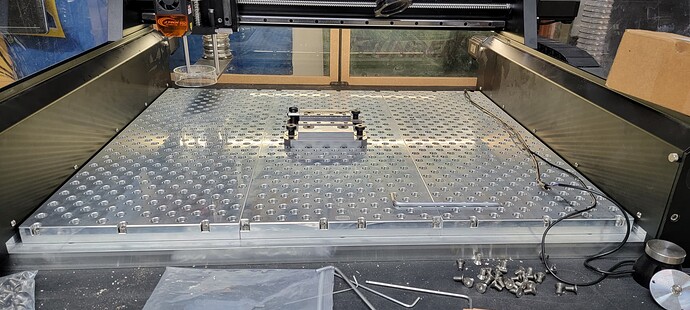

Were you able to mount the plates in the outer most position? The row of screws along the bottom of the sheetmetal is preventing the fixture plate from sliding over far enough on mine.

@SLCJedi , Josh, tell us about the clear plastic with all the holes, assume to protect the fixture plate?

Correct. I think it was a limited run. I don’t see them on the SMW site anymore.

I have zero intention on turning it up but should I need to will turn it down.

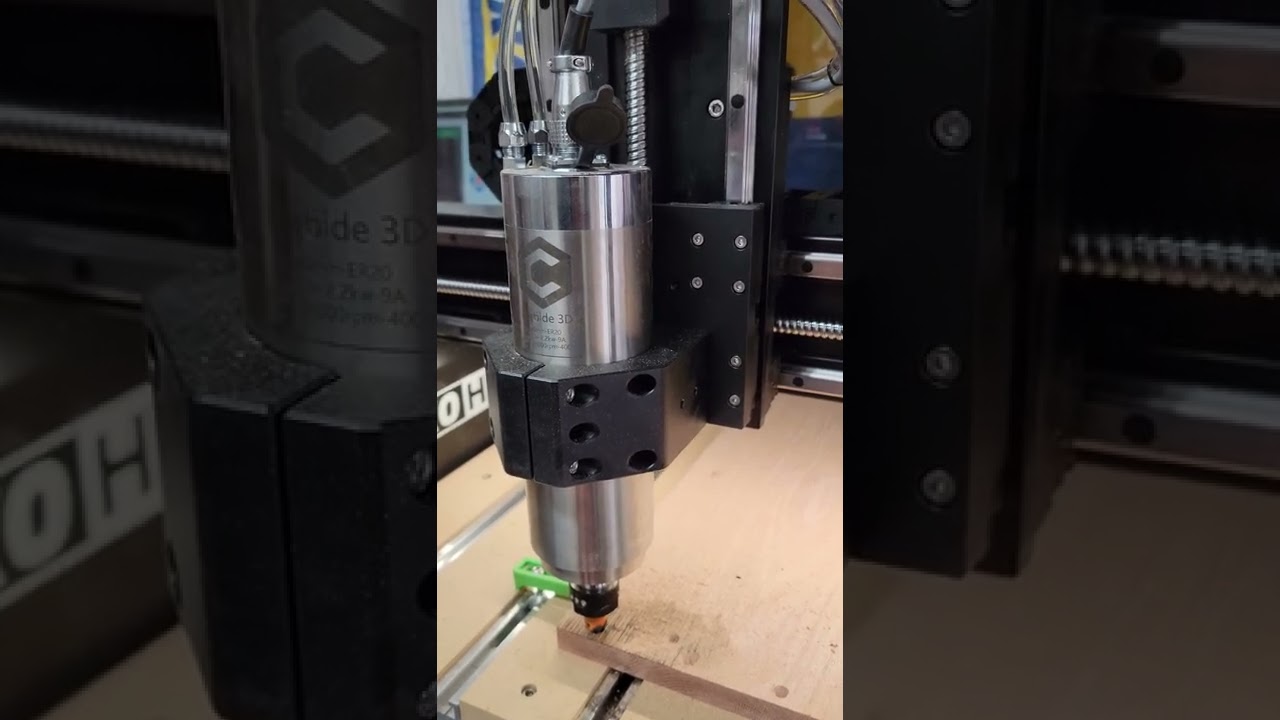

So in doing some vcarve testing today it appears i am losing steps on z and binding. I’ve posted the same file in vcarve pro and CC and ran it in Gsender and CM both with same results. Upon closer inspection I noticed this (see video). There appears to be significant slop in the z-axis ball screw. I assume this is due to loose bearing nuts?

And here is immediately after the bit plunged ~10mm into the work, the stepper doesn’t seem to have enough torque to pull itself back up. I am jogging it up the whole time and it finally breaks free and rises.

And also the z-axis falls by itself when the machine is powered down.

Most definitely binding in the bottom 1/3 of travel. I removed both nuts on the ball screw, both were finger loose. Even with the ball screw completely free the axis won’t travel all the way down.

It looks like the DAC assembly is loose.

Please email a ticket into support and we will sort it out.

The dropping of the Z axis is totally normal when powered off.

Ticket submitted. I was able to tighten the nut on the ball screw and take up the slack. The nylock part of the nut was untouched and had never engaged the threads if that tells you anything. I used around 12 -15 lb/f on the ball screw nut and about 5 on the bearing retention nut.

Thanks Cody, glad this is resolved now. If you have any further issues please let us know.

Luke

Am I crazy or did my spindle used to rotate forward and reverse with M3 and M4 respectively? I unhooked it again to move the machine and now both rotate it forward.

I doubt it. Because this comes under HSM we don’t wire up counter clockwise.

probably a good call, mine misses steps on tight adaptive paths with anything above 120-130ipm range.

Does the HDM ship with oil in the linear guides? I’ve been having issues with z binding and a moan from rapiding in the the x+ direction. I aquired a compatible way lube and injected a cc in each guide in x and z and all my issues went away. Anyone else seeing this?

Linear guides need fairly regular oiling to avoid binding up, corrosion and to help keep chips and dust out. I found on some Hiwin that the seals built so much friciton they bound on the rail when not oiled (that set from Hiwin direct only had enough oil for transport).

I check mine by wiping down the linear rail to dry it of oil, then jogging the axis across and checking to see that there’s a fine oil film left behind on the rolling contact surfaces. If they’re dry, then I squirt more way oil into the blocks.

My z was binding so badly it would fail to home. Seems better now. I guess I’ll just have to make this a weekly maintenance item.

I only need to oil mine every few months, but a weekly check that the rails are still lubricated sounds very sensible.

I’ve been working on my dust collection setup and here is what I’ve come up with. I’m using the sweepy pro on my HDM and wanted a modular, removable hose assembly that would go from the sweepy pro to the top of my enclosure, the out the top. I wanted to be able to remove the section of hose from the sweepy to the top of enclosure, and also needed to remove the external connection so it will fit out of my shop door for cleaning.

I still need to shorten the screws but the gap between is where the roof of enclosure will be. Magnets will locate and hold the fittings in place. I also plan on making a velocity stack for the internal fitting for smoke extraction when lasering.