Is there a way to create a flattening tool path that starts outside the edge of the work piece? I am using a 1.5” flattening bit that has the blades on the outside of the bit. I do not believe a pocket tool path would work on this type of bit. Any help would be appreciated.

I thought there was a new Face operation in CC v8, but no.

It might be in CC Pro

See:

It’s only in the pro version.

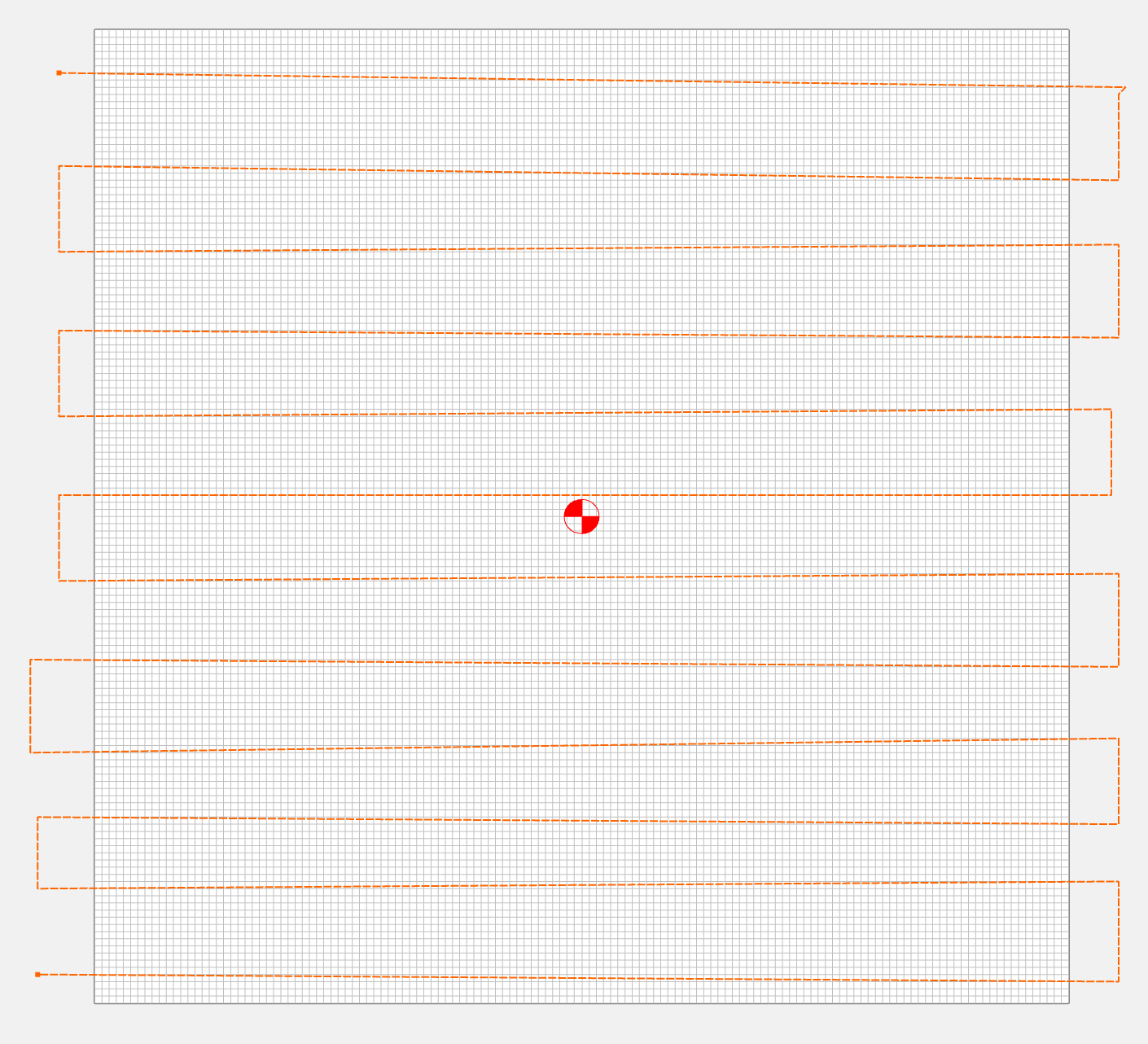

If there is room just make a rectangle bigger than the object being flattened. On my SO3 I purposely made my spoilboard smaller than the maximum cutting area so I could get my whole spoilboard flattened. On the SO5 and SO4 the hybrid spoilboard cannot be completely flattened in one operation. I believe @WillAdams has suggested on those machines to turn the mdf slats around 180 degrees so the back (now front) can be flattened. However if you just do a pocket the tool path starts at the center. So you can just draw a zig pattern that is closer together than the width of your tool and do a contour with no offset. I am sure the SO5 and SO4 folks will pipe in on how they flatten large objects like their spoilboard.

I crudely drew this in CC.

Basically you are creating a raster pattern for the bit to follow.

The raster pattern would need to fit inside your physical limitations of your machine and you material size would need to be bigger than your actual material.

I think that the Face operation should be in the normal CC version.

It’s a 2D operation that was missing in the previous versions, so it should be a new feature in CC.

Just my opinion.

For a free tool to generate such toolpaths see:

First I have to say I appreciate the Carbide3D environment. The cost of getting into a quality HW product and reasonable SW has been enjoyable. I do not use CC very often because I use Fusion.

Initially I was using CC for everything. I ( like almost everyone else ) needed to flatten stock.

@WillAdams has provided a lot of effort to accomplish this basic task for newbies like myself.

The effort in CC to generate a toolpath interactively by drawing it, is painful to say the least.

CC is not parametric, so each project needs a new layout.

This is a basic 2D Tool path which I felt needed to be included in CC. This is used by ALL CC users if their project is 2D or 3D.

To include the Face Tool path in ONLY CC Pro is a bit of a slap in the face to CC users in my opinion. If a user has no intentions on doing 3D, you are now required to pay the CC pro license ( yearly) to get the one 2D Tool path generator.

I actually went to Fusion initially for the Face operation.

I hope C3D reconsiders this marketing decision for the benefit of ALL CC users.

While I understand and respect your comment about the face tool operation, I performed this with a simple pocket tool path in standard CC when I purchased my S5Pro. I was able to get to this solution easily with the provided info on C3D’s site.

This allowed me to learn and understand the software and machine which I just assembled. I’m the type person that wants to know how it works and why. Without the “why” I can’t ensure the “how’ is doing what it’s supposed to. If that makes sense.

Without upsetting a bunch of folks, I have witnessed the unintended consequences of making procedures “better” for newly qualified operators. While this did allow them to perform evolutions more consistently, their ability to deal with issues not specified in the procedure diminished. This was due to the procedure being so specific that users no longer had to have detailed system knowledge to perform them correctly.

I’m a believer of having base knowledge of a process to ensure proper operation of said process.

Again, not posting to cause argument or disrespect, just another point of view.

No disrespect taken Your opinion is 100% valid as is your solution.

I agree working out the details is the way you learn fully. Having a lot of guard rails is not always the best or the most efficient.

My thought is to save @WillAdams some re typing and the user community to keep moving forward. Sometimes a simple lesson can be intimidating and put users off.

My point is more about packaging.

Thanks for taking the time !

I get paid to help, and mostly it’s copy-paste — anything I re-type too often gets added to:

https://old.reddit.com/r/shapeoko/wiki/faq

for copy-pasting from.

Which features end up in which version is way above my pay grade — that said, we appreciate the input, and we’ll have to see what happens in future versions.

LOL! Without the detailed knowledge is how those students found out how efficient it was to get into the guardrails….

Noooooo ![]() I was so excited for CC v8 so I wouldn’t have to manually adjust/create raster polylines for every new project. It’s such a source of friction in the workflow. But I didn’t realize it was only going to be in the pro version. I stumbled across this topic because I couldn’t figure out where the new toolpath was and searched around. Super frustrating. I am a hobbyist that has no interest in 3D carving and will never be able to justify the cost of pro software (CC or vectric). Simple QOL features like this would make CNCing so much more pleasurable. I want to spend more time making stuff and less time fiddling with the nodes for a basic utility operation that I run on pretty much every project.

I was so excited for CC v8 so I wouldn’t have to manually adjust/create raster polylines for every new project. It’s such a source of friction in the workflow. But I didn’t realize it was only going to be in the pro version. I stumbled across this topic because I couldn’t figure out where the new toolpath was and searched around. Super frustrating. I am a hobbyist that has no interest in 3D carving and will never be able to justify the cost of pro software (CC or vectric). Simple QOL features like this would make CNCing so much more pleasurable. I want to spend more time making stuff and less time fiddling with the nodes for a basic utility operation that I run on pretty much every project.

Respectfully have to disagree with this. What you’re describing is intentionally adding friction to the user experience. I empathize with the support aspects of running a CNC business, but if you make things too difficult for power users, they’ll go elsewhere. I have long wished for both CC and CM to have advanced/power user modes that you can toggle on to bypass some of the newbie-protection features built into them. I’d be totally fine with any features behind that toggle being officially unsupported too.

Perhaps you misunderstood my post, I never posted that I was objecting to the “facing” button as an option. I merely stated that I think it’s good to know and understand the base use of the software and a facing tool path is easily designed. A facing tool path button would speed up the process.

In short, not against added user features at all and I enjoy getting into the base level of the software to understand the entire process.

I guess the definition of a power user in my mind already assumes that software much more advanced than CC is being used in business’s. Not that a business can’t use CC.

This one has some different options that can be useful.

This is really cool, I’ll give it a shot! I’m assuming “Cutting Direction: Both” does the traditional left/right/left/right raster path?

Thanks for making this and sharing!

Correct.

I highly recommend previewing the gcode in something like ncviewer before you run it.

This topic was automatically closed after 30 days. New replies are no longer allowed.