WillAdams

December 20, 2025, 6:44pm

5

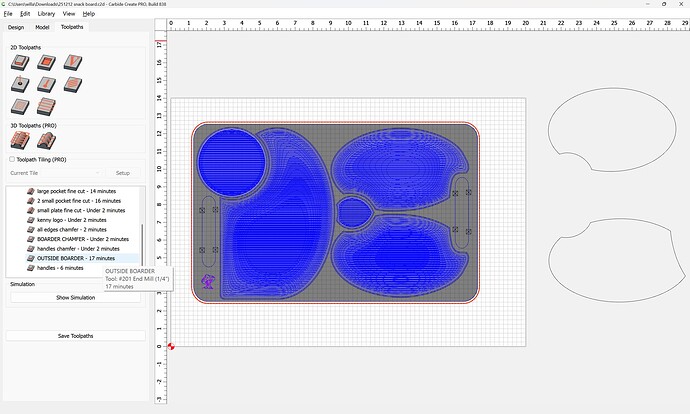

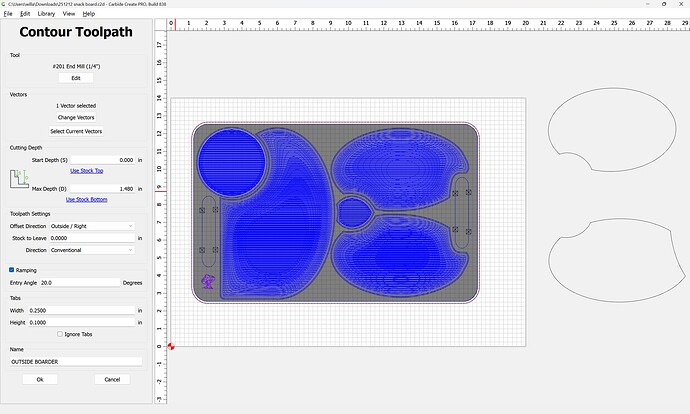

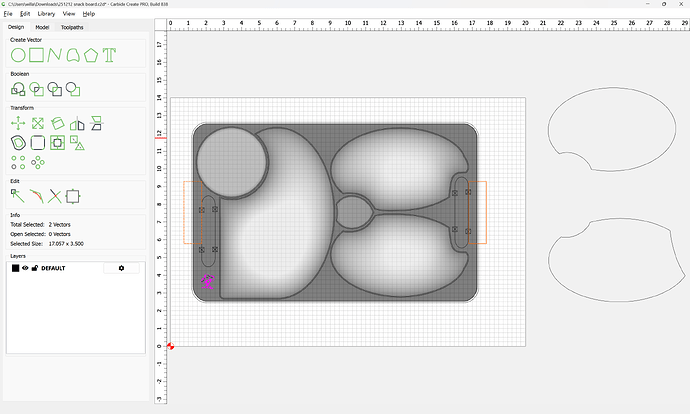

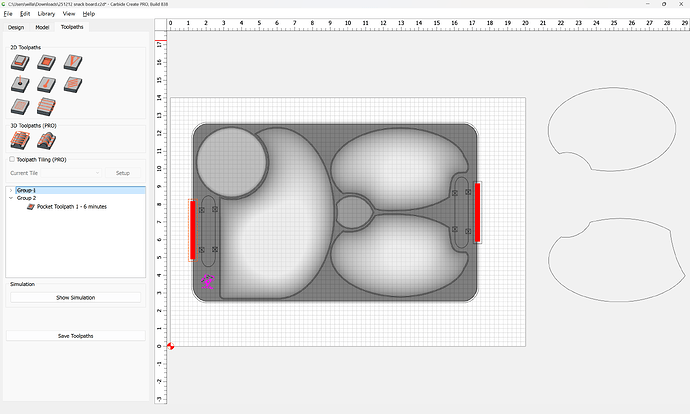

You should cut out the handles before the outside boarder:

A #201 endmill does not have 1.5" of cutting flute length:

you’ll need a "long reach endmill for that, and you really should consider Climb vs. Conventional Milling and tooling engagement — where possible avoid slotting and add geometry and cut as a pocket

While cutting up vacuum extension wands for this is expedient, it’s a bit problematic given that Shop Vac recently filed for bankruptcy, was bought at the last minute, and production hasn’t caught up.

I need a receptacle for the Sweepy 2.0 dust fitting — one option would be to purchase one from Woodcraft, but Carbide 3D sells blocks of HDPE:

which looks to be just barely big enough for things to fit.

Measuring the hose fitting I get a diameter of ~63.5mm — offsetting that twice we arrive at…

and/or

One technique which is often suggested to avoid slotting is to add geometry around a part which one wishes to cut out and cut as a pocket down to tab depth — here’s one technique for that.

In this case, the project is a bevel gauge which will be cut out of 0.0625" (~1.5mm) thick aluminum:

[bevelgauge]

Due to the narrowness of the angles, an 0.03125" endmill has to be used, so after importing and scaling the file (we will be cutting out one which is 3") we select the perimeter and offset it tw…

and consider leaving a roughing clearance and taking a finishing pass.

One which has a cutting flute length equal to or greater than the thickness of the stock — pretty much any tool should work.

Big thing is the toolpaths — if cutting out, rather than just cutting a slot:

[image]

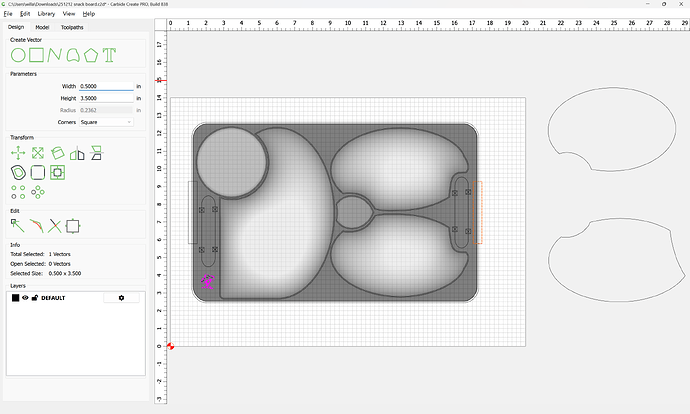

Offset to the outside by endmill diameter plus 10% or so:

[image]

[image]

[image]

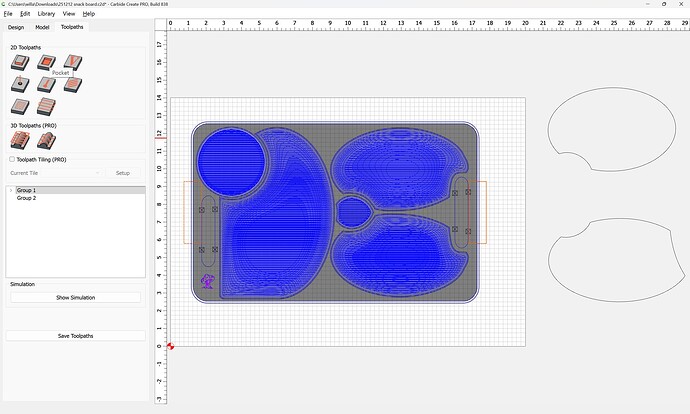

Then cut as a pocket:

[image]

down to tab height or the penultimate pass:

[image]

then move the contour down to below the pocket and start cutting at the bottom of the pocket:

[image]

and…

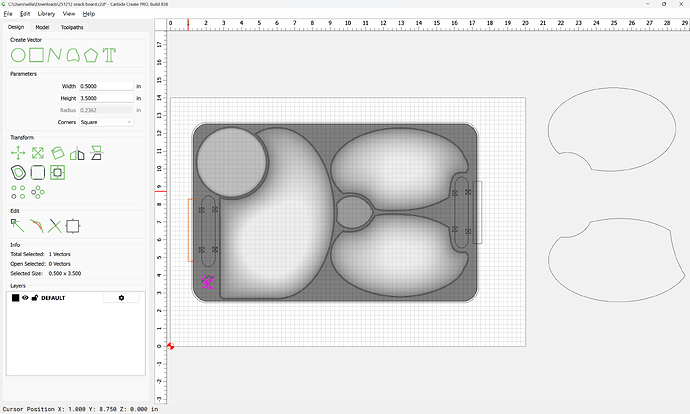

(same for the handles)

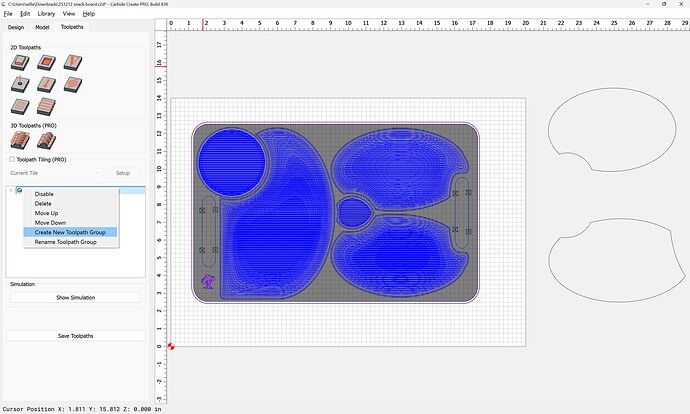

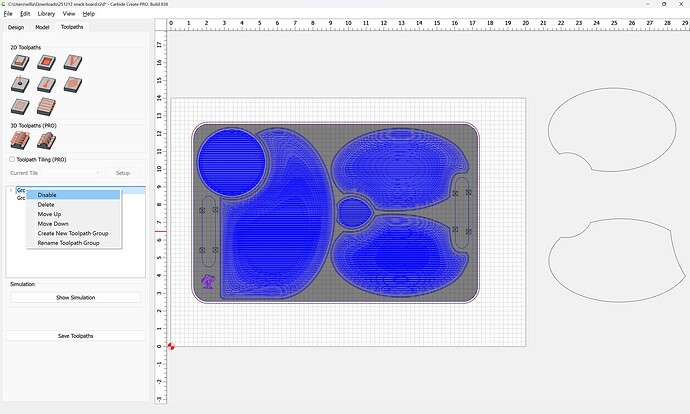

I’d simply add another group and add a shallow cut along the edge (note that you’ll need to maintain registration — probably the best approach would be to cut half-way through on each side)

Adjust the dimensions/placement a bit:

I believe those will need to be mirrored depending on the orientation of your flip, see:

VIDEO

1 Like