I got a bit carried away. What is that sucking sound?

So, your first love is making aluminum, perhaps a few steel chips, but occasionally you want to carve up some wood too…

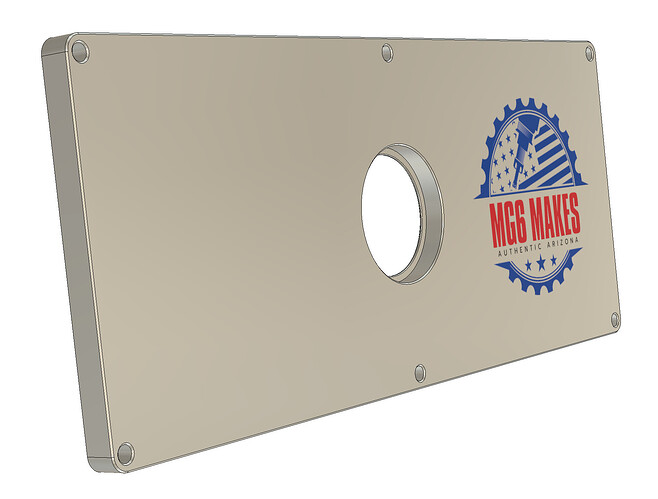

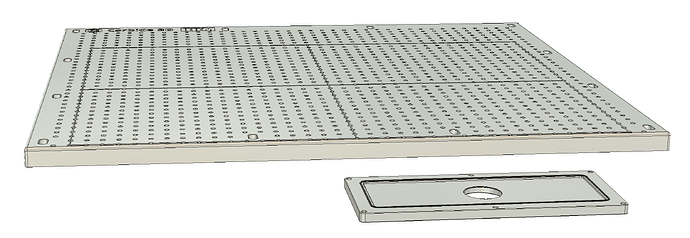

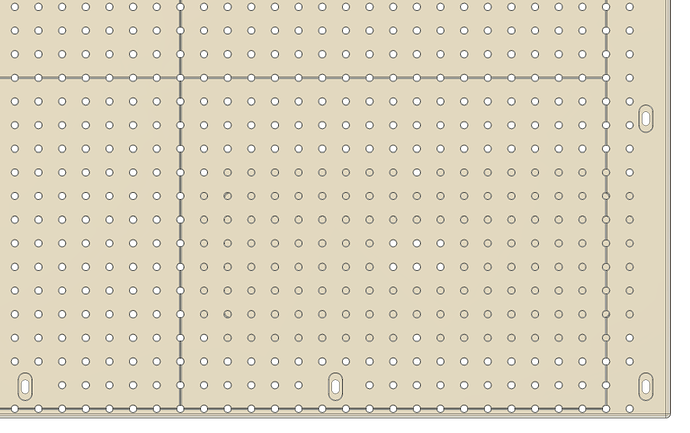

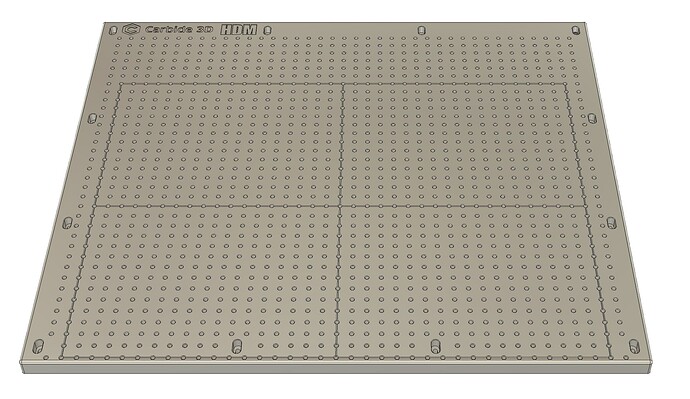

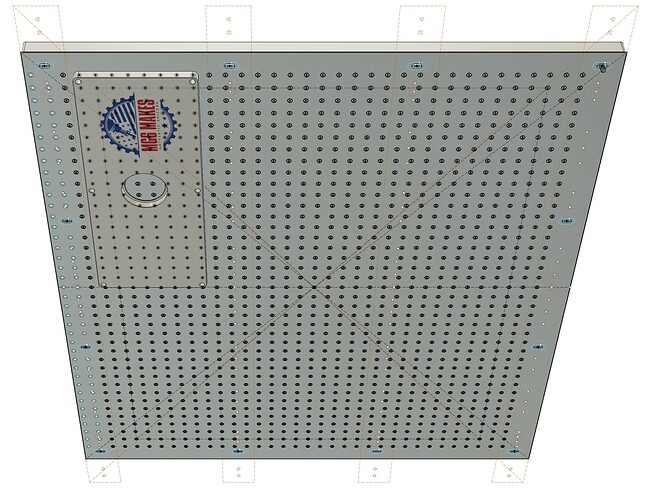

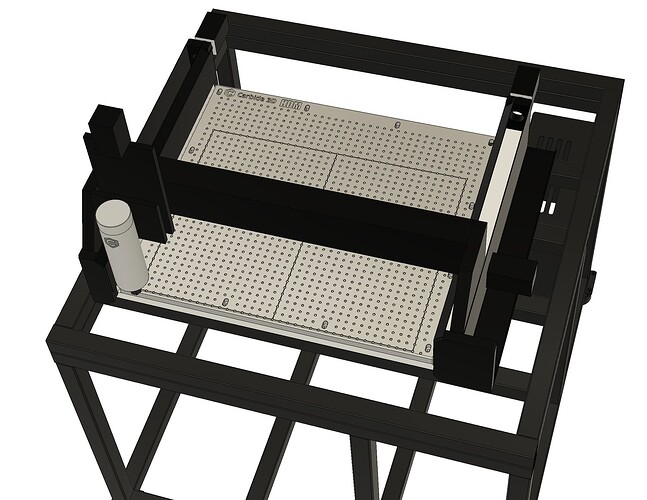

I also made significant updates to the fixture plate. Now has slotted mounting holes. I could not guarantee the 1st Gen HDM nomad tubes or whatever the C3D guys call them would align perfectly. PLUS, all this is based on the HDM CAD model I found and downloaded with some minor measurements I did against my machine.

I moved the HDM work area movement outline to roughly where it is IRL.

Cheers, I’m done with this one. Going to have my guy price it, all machined. But I already know its not cheap. I found the 6061 plate stock around $500, plus all the machining. Would be interesting to build, but I probably will not.

Could fit up to six “Vacuum Plates” onto the bottom of the HDM Work/Fixture Plate using the ¼"-20 grid holes.

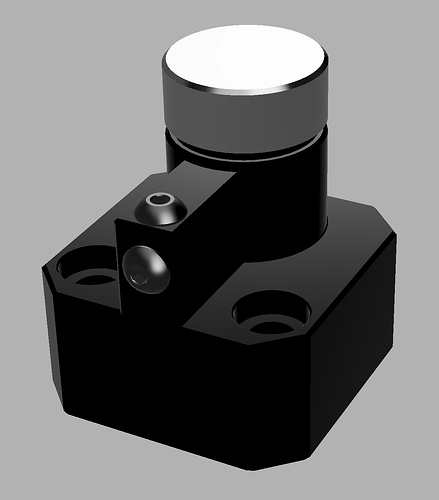

Tomorrow, I am going to model the bitsetter and modify the plate that it will mount directly to the fixture plate near home at the back. Maybe. May not work back there.

Question. Could not find an easy answer from search. AI says yes, but I don’t believe it.

How does Warthog know where the HDM bitsetter is installed for z height? The setup checks for x, y only correct?

Reason that I ask is that the fixture plate above will land at a different height than the stock slats (0.703 IIRC). Will this mess up the bitsetter for setting tool depth later on the fixture plate? is this adjustable?

thanks,

MG

The BitSetter measures the tool length offset relative to its position after probing — so long as its vertical position relative to machine origin doesn’t change, the measurement will be consistent.

Note that the vertical position has to be within a range which is compatible with the probe command as issued by Carbide Motion — there’s a certain height it begins at, and it probes only so far down from that position.

Makes sense, thank you Will. So, I was going to recess the bitsetter into the fixture. I may do that and land it right at ~.0703, which I believe I have seen folks with it on top of the slates and should work.

I remember reading somewhere that it tracks vertical position relative to the last measurement?

Should have thought more about quick release type setup for the suction plates. If it’ s an exercise several hundred times when it could have been more of an exercise during the design phase you can probably figure which one will pay off more.

Like one larger plate to retain 6 smaller on say a drawer slide setup that can be engaged or disengaged quicker and maybe countersunk 1/4-20 SHCS for quick installation and easy hole recognition.

No, it measures the absolute tool length offset, and then applies that — since each is relative to the same absolute position (machine Z-axis origin) the effect is much the same.

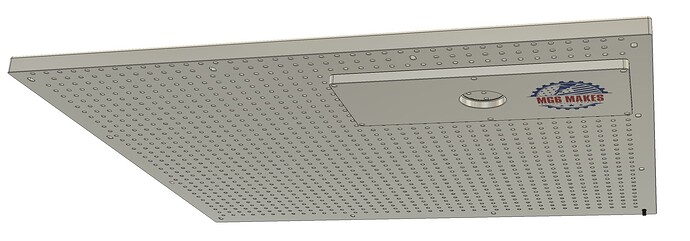

operationally, the plates would stay installed. Only turn on the vac when you need suction. In this case, the HDM nomad tubes block drawer slides and all that.

I don’t plan on building this, but if I did I would probably only build two vac plates and install them in the front bay.

Just for your future reference, everything is designed in metric. That measurement translates to ~30mm in case you want a cleaner number.

Is there public drawings of basic arrangement of an Spro 5 ? I would be interested in enough dimensions to simplistically model the components.

Including the machine zero point, table slots and maybe the default z height probe.

I understand that you don’t want someone to reverse engineer the product, but it would help in planning.

IIRC I found an SO5 model when I was hunting for the HDM.

@wmoy Metric! My eyes, my eyes! My brain! It hurts us! ![]()

Right okay that makes sense my first instinct was coolant ending up through the vac pump system. There is also the option of quick hold downs for throwing in a peice of plywood or mdf and then using vacuum pucks for smaller wood projects, this would also cover your plate but reduce you to probably 1" working height.

I have backed off on flood coolant. Just going to use a Stupid Simple Tools alcohol mister on my setup. But yeah, would have to address those issues with flood. Only six bolts to remove the vac plate. It’s only time and a few busted knuckles.

Fair enough! Your enclosure still looks deadly.

I have not mounted a .50 cal on it, yet. How is it deadly?