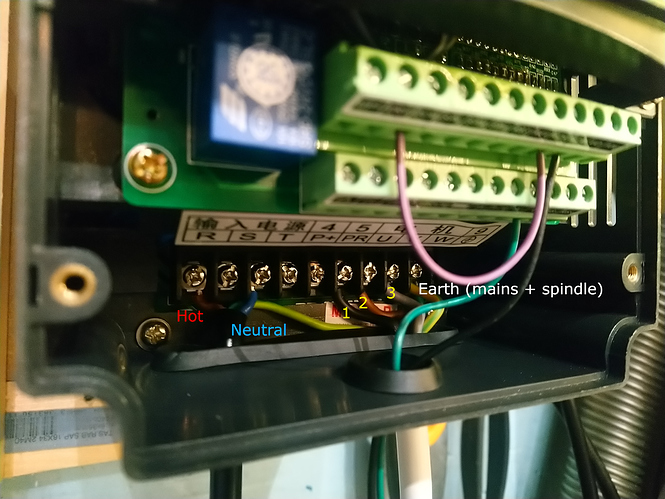

and while I’m here, two wiring snapshots .

220V Hot and Neutral wired to R and T (apparently, it would also work with R and S or S and T too), Earth connected to the VFD’s earth terminal

Spindle’s aviation connecteur pin 1 to U, pin 2 to V, pin 3 to W, pin 4 to Earth terminal

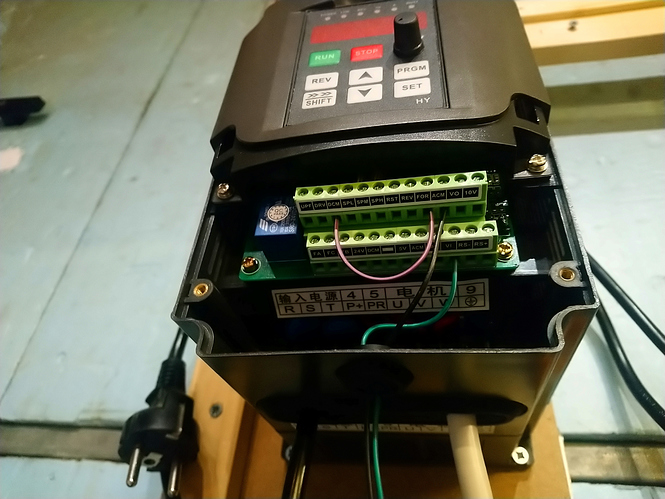

For control signals, I followed @Luke’s instructions religiously:

- FOR(ward) to DCM(ground) = forces forward rotation, i.e. the right direction.

- Shapeoko’s GND to ACM (ground)

- Shapeoko’s PWM to VI (voltage input)

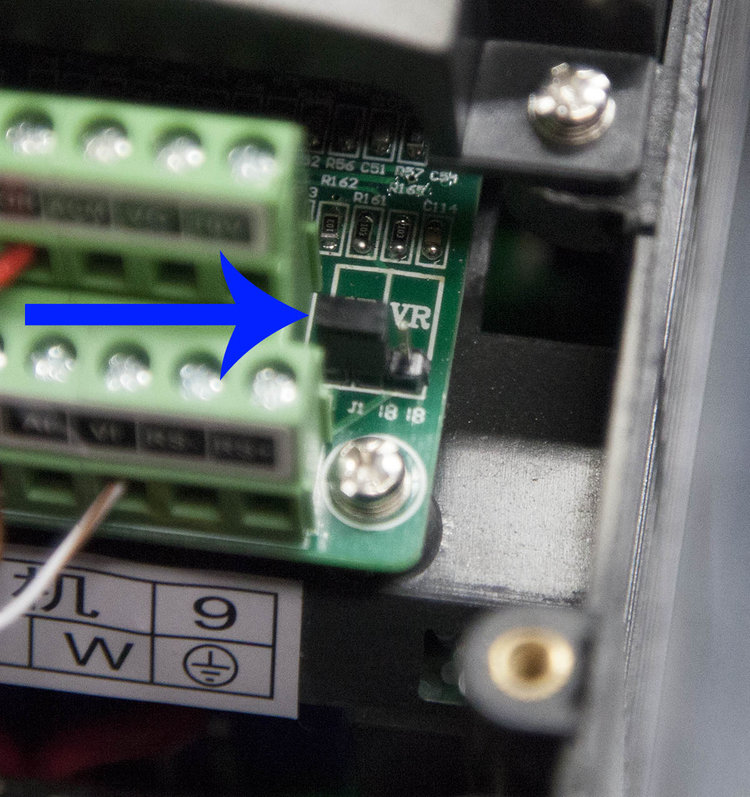

EDIT: I forgot to include a very important HW setting that is easy to overlook: there are header pins located to the right of the green connectors, and the small jumper must be set in the “VI” position for external PWM control to work:

Oh, and I finally flipped the switch and everything worked fine, the spindle is not humming quietly at low RPMs. Call me crazy but I am more or less following the chenglish advice from the vendor:

"Spindle in the preservation and transportation, high-speed grease inside the bearing state will change, customers should be running at low speed for 30 minutes. 3000 rpm and then follow the poor increase, run 20 minutes each"