That is exactly what I wanted to hear - thanks!

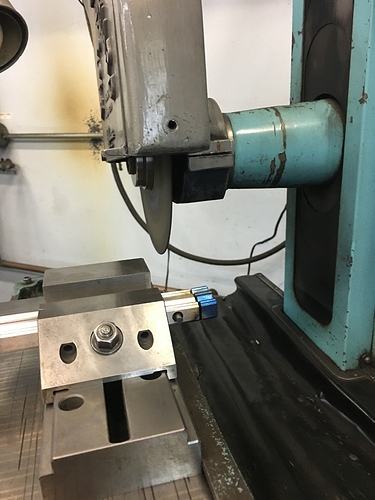

A friend used a zip wheel in a surface grinder to cut one end and a Bridgeport to cut the other for my X-rails. My Y-rails haven’t come in yet, and my friend didn’t want to take my money so I plan on cutting them at home.