I was quite pleased with how the back of my latest trivet turned out, so to avoid making YET another trivet I tried something else, something abstract, that would serve no purpose (other than being cool, hopefully).

TLDR: skip to the last pic and tell me where you would go from there.

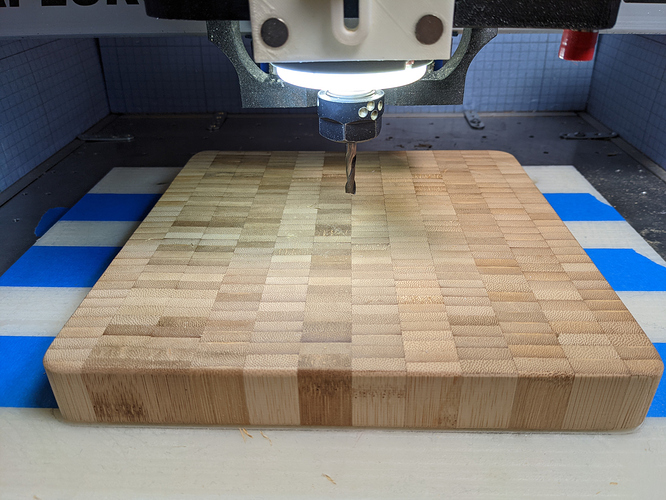

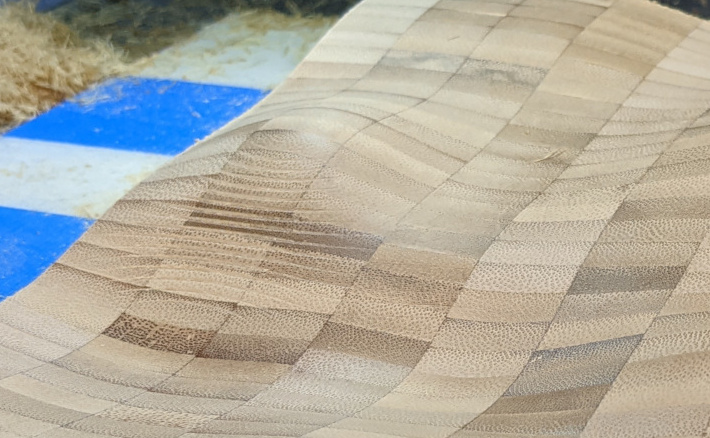

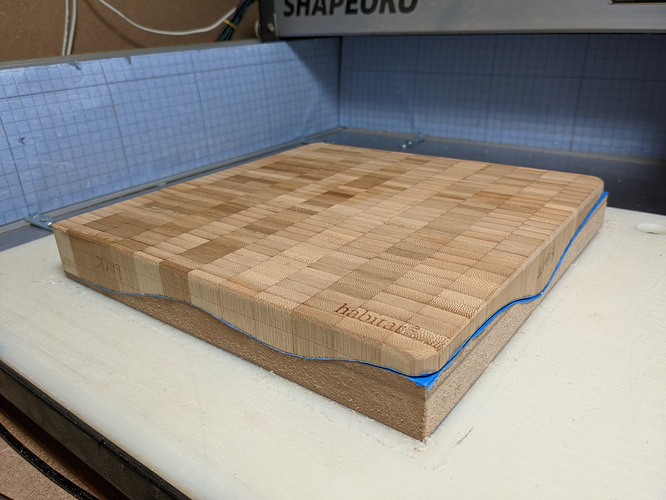

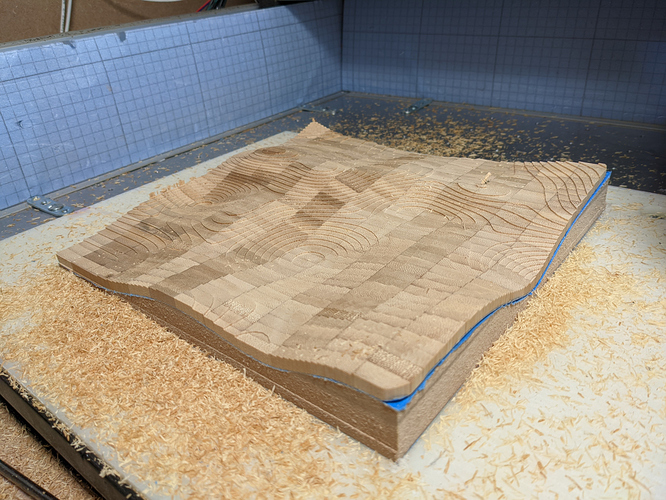

So I started with this nice thick block of “endgrain” bamboo again:

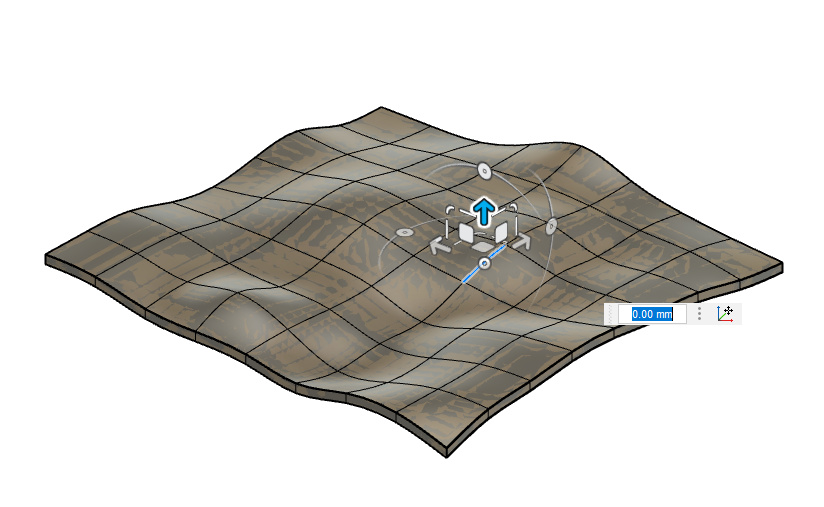

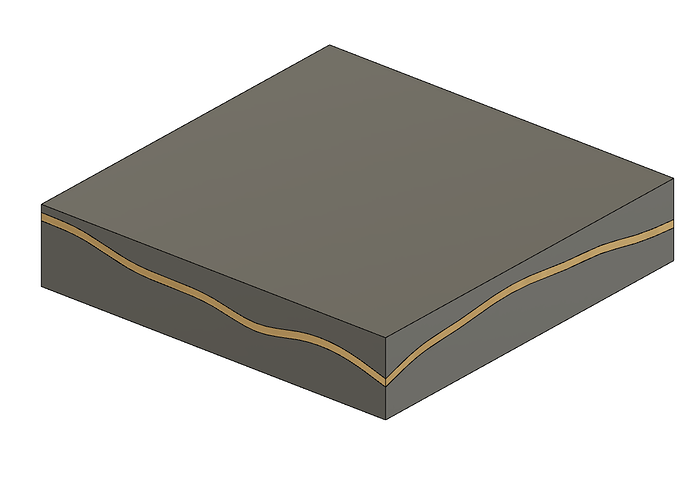

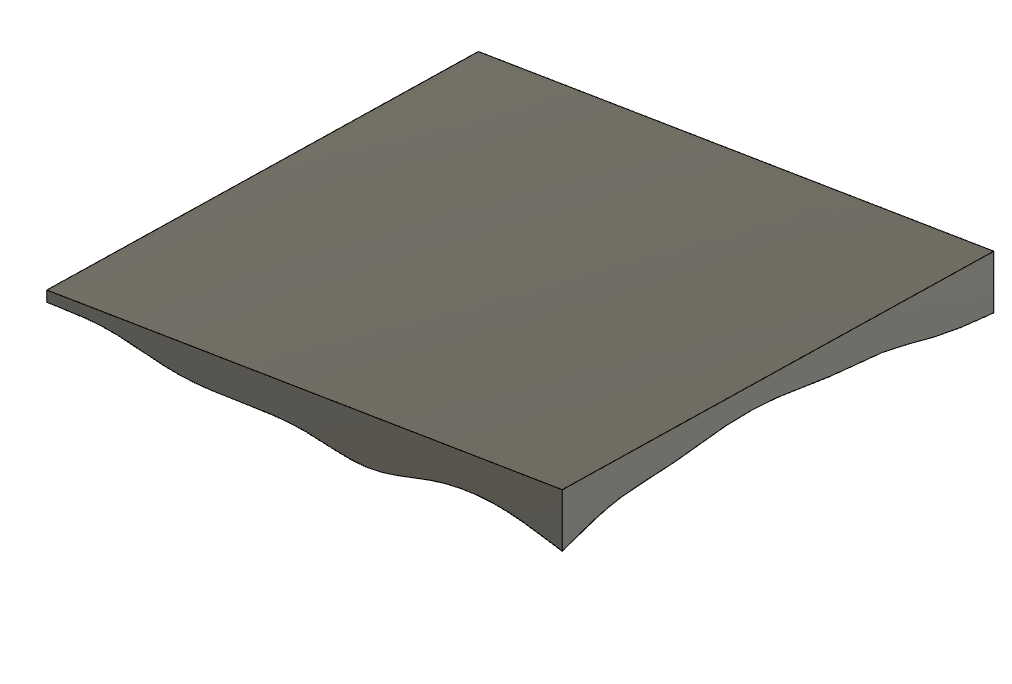

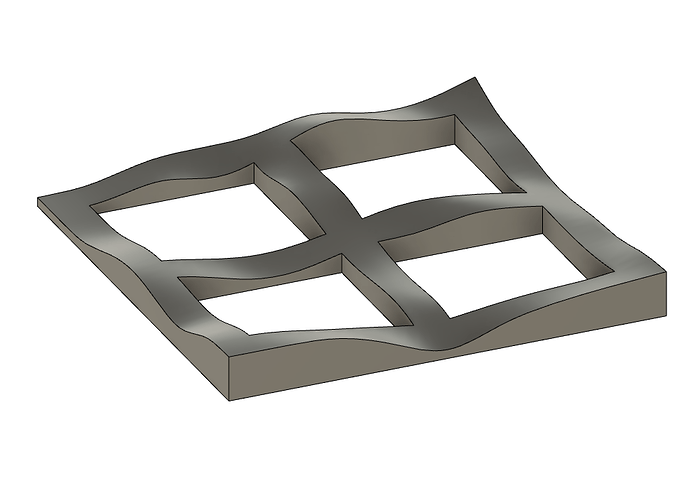

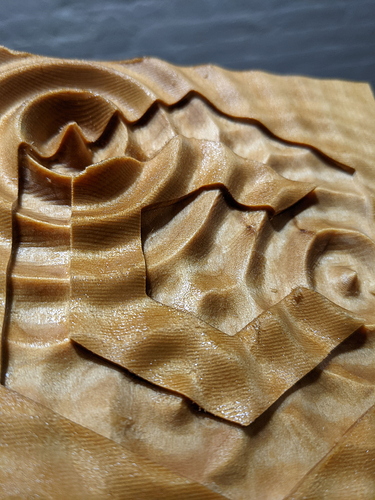

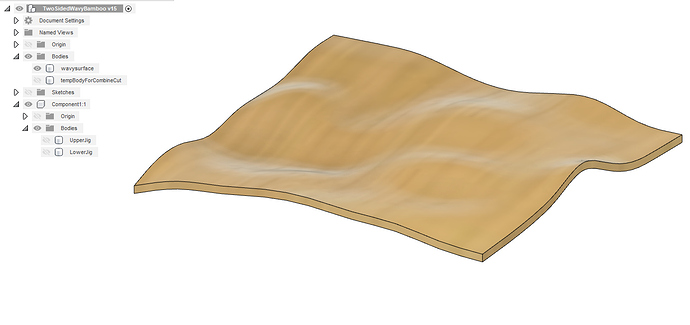

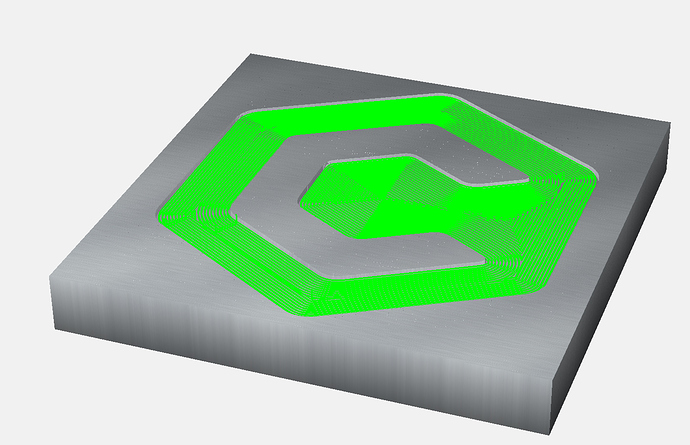

And figured I would play with Fusion360 form edit mode again, started from a Plane, subdivided it a few times, pushed/pulled on edges using the Edit Form tool, and thickened it to a 5mm solid, till I got this:

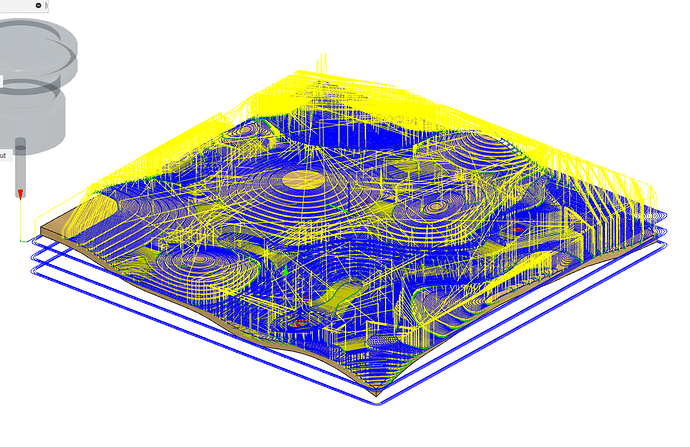

The roughing cut for the top face was easy,

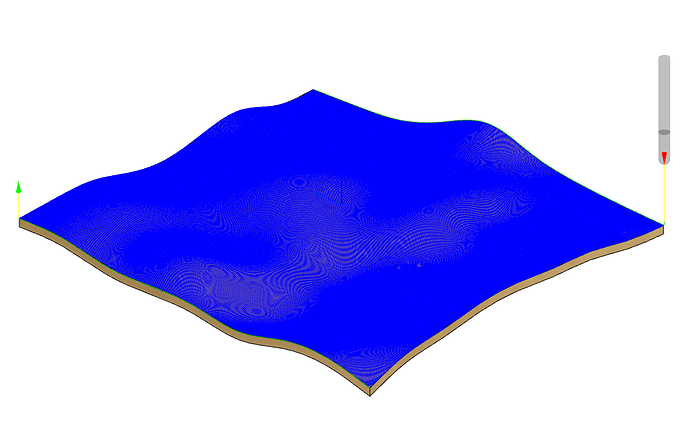

And parallel finishing worked fine on such a continuous surface,

Something weird happened in that area:

Not sure what was wrong in the toolpath or cut, anyway I chose to ignore it to stay focused on the end game.

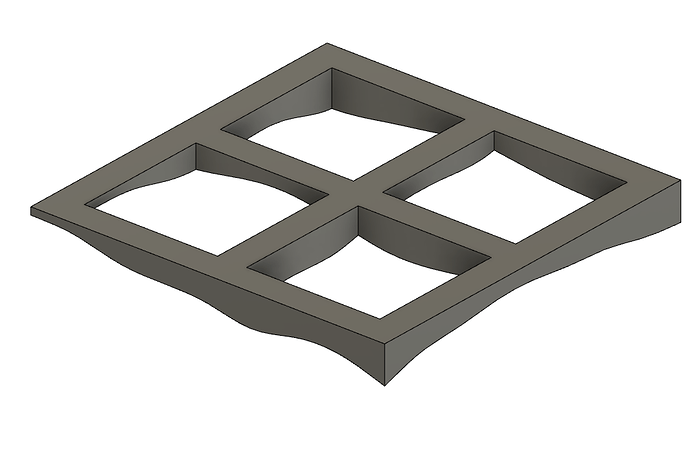

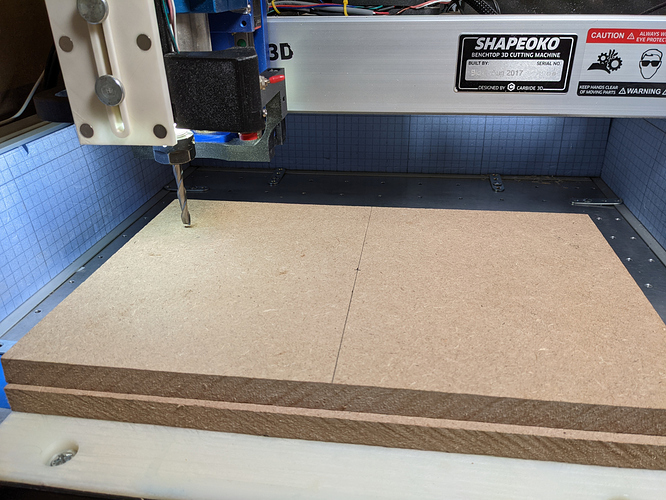

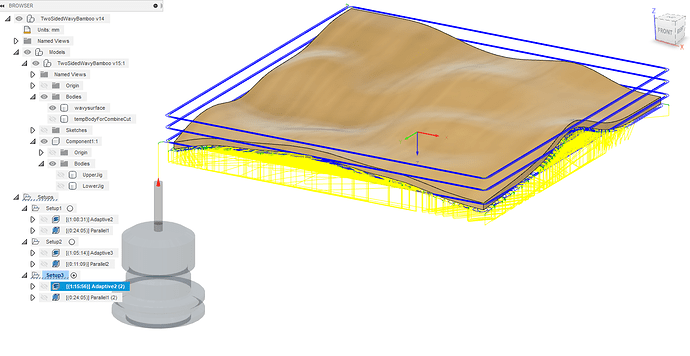

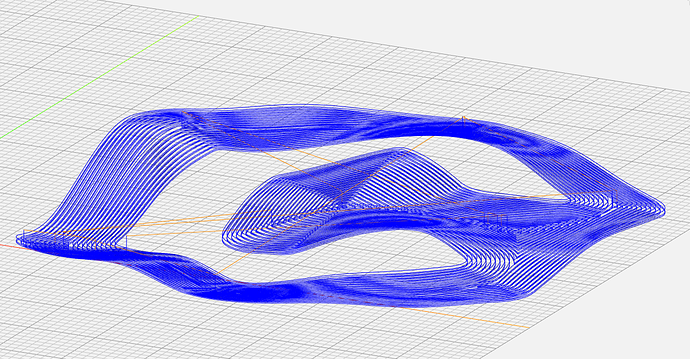

Then came the interesting part: cutting the other side. Which of course required a jig, so I first used the “Combine” tool to split a rectangular shape in half using the wavy object as the cutting tool:

The upper part is the jig that will support the piece for milling the underside:

I added pockets to later be able to “push” the piece from the jig (more on this below)

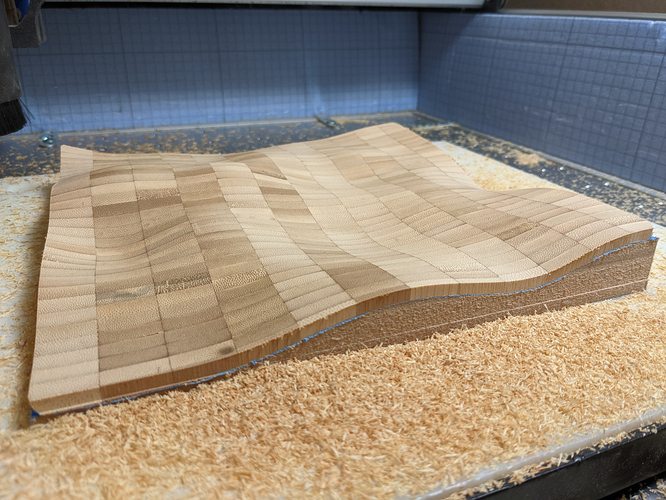

When flipped, it looks like this, it’s obviously a negative version of the wavy surface, and the remaining material should be more than enough support to hold the piece:

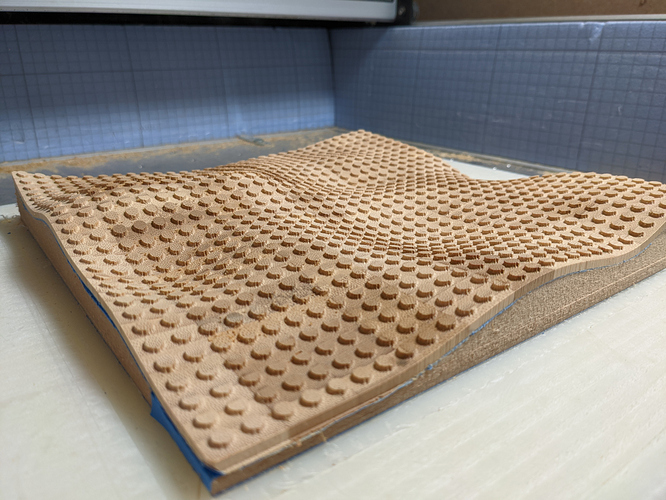

I glued two 3/4" sheets of MDF together to have enough thickness, and installed my long-LOC 8mm square endmill:

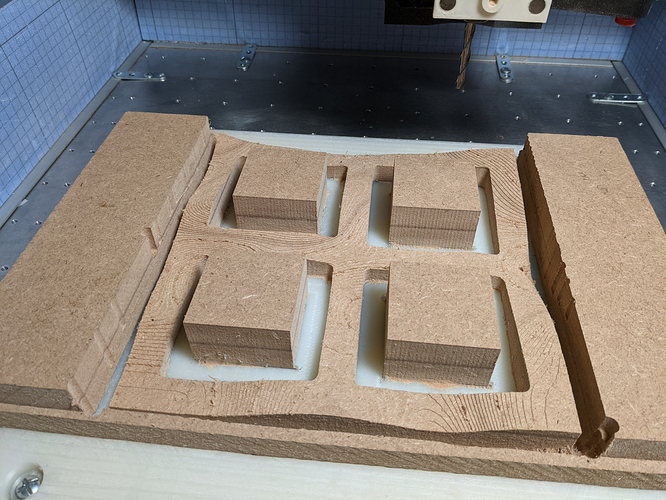

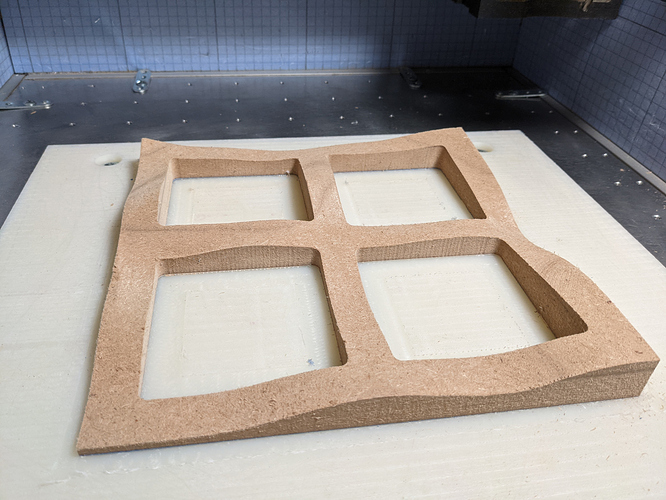

A bucket of dust later, I had this:

(side note: running an 8mm endmill fast through MDF with a sub-optimal dust collection, is a good way to end up with massive amounts of MDF dust all over the machine…sigh).

I then removed the outer and inner pieces out of the way,

and ran the finishing pass for the MDF jig:

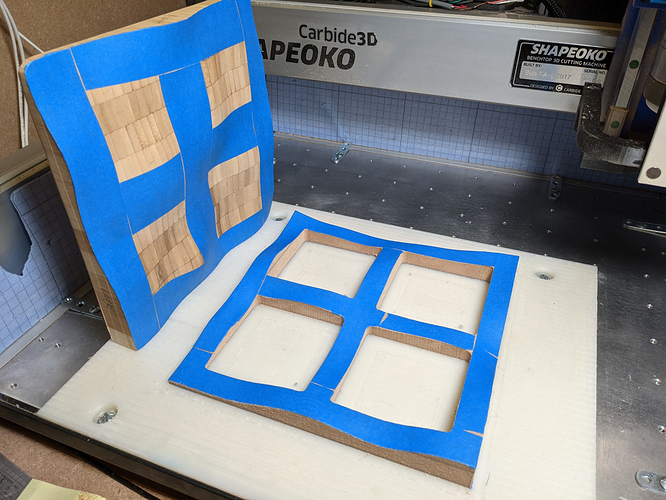

And then…tape & glue party time !

It’s a satisfying moment when the piece falls in place perfectly onto the jig:

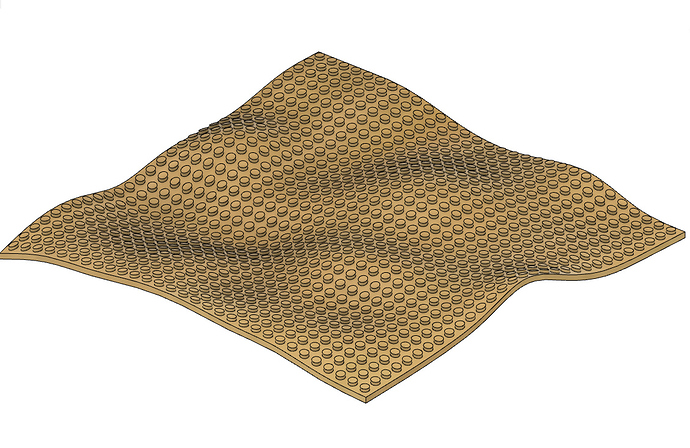

Then I CAMed the other side of the wavy surface, by just creating a new stock setup with axis flipped

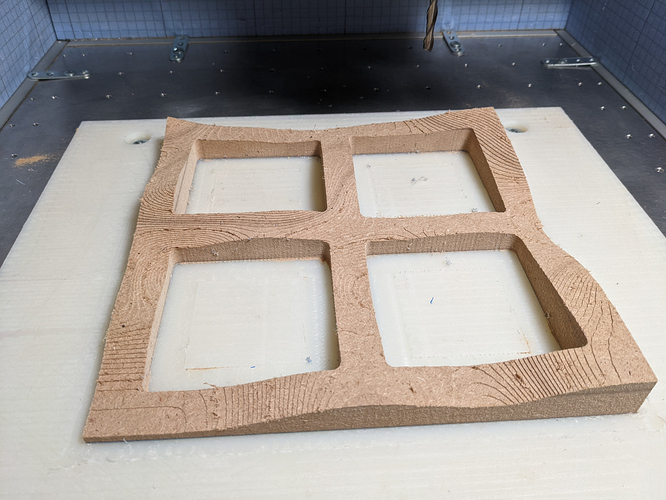

Ran that,

followed by the finishing toolpath for that side:

And…that’s where I am. NOW the question (for you guys),

- do I just separate the piece from the jig, sand it, oil it, and call it done ?

- or do I keep it on the jig and carve something else in it ? I have this urge to mill hexagons to end up with grid-like wavy surface, but it may be too much and not look as good as I think it will. Or carve letters through.

Please let me know what you would do at this point ?