So I finally got tired of the Dewalt Router and it’s wobble on the axis and the need to replace brushes all the time and installed a nice water cooled spindle. I figured 800W is plenty for what I use it for…

Also got a matching 65MM diameter HD spindle mount from Carbide3D… that thing is SOLID and it looks like no tramming needed kind of precision.

After I installed everything, made some mistakes, ordered some replacement parts … time to make some test cuts.

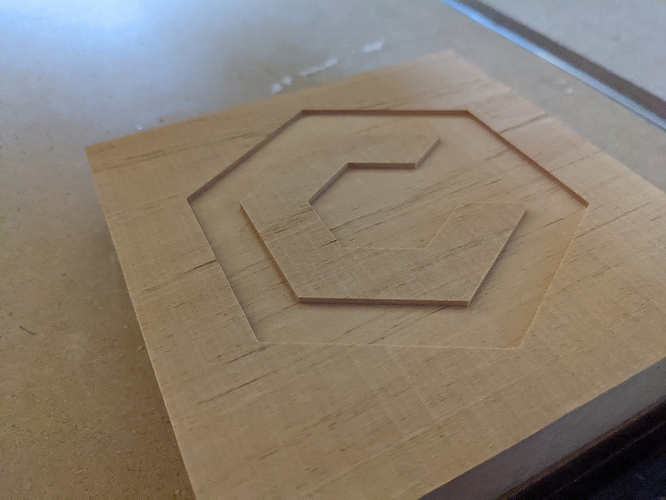

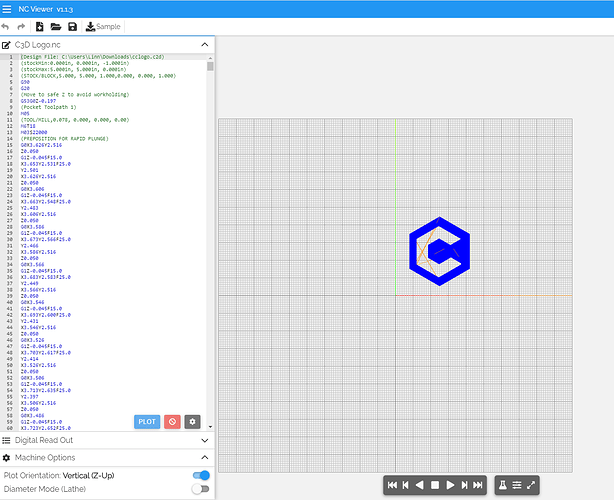

Step 1: Basic 2D “hello world” kind of cut

Simple Carbide3D logo, drawn in Carbide Create and cut with one of my favorites, a 2mm downcut endmill

Result: Very nice. The pockets are SMOOTH. No tramming needed. Love the spindle (quiet!) love the 65MM HD Mount

Gcode: cclogo.nc (86.5 KB)

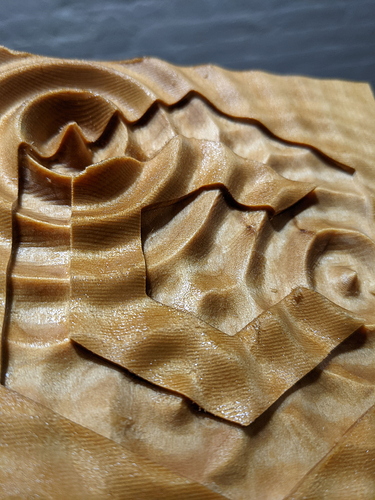

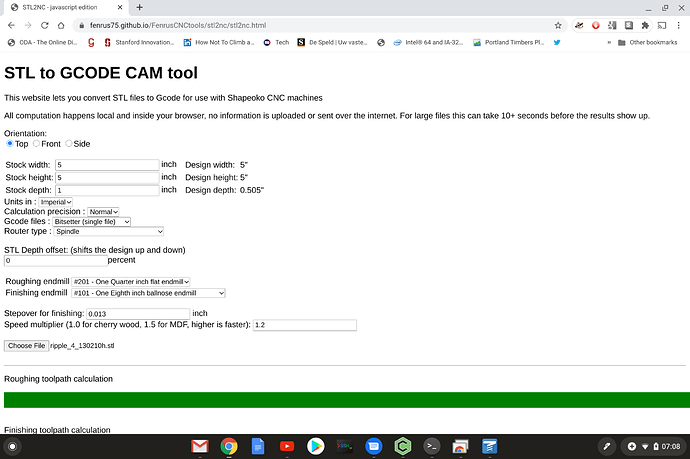

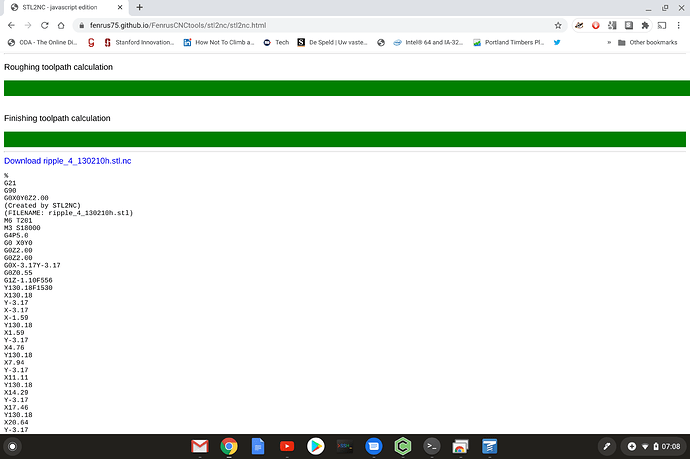

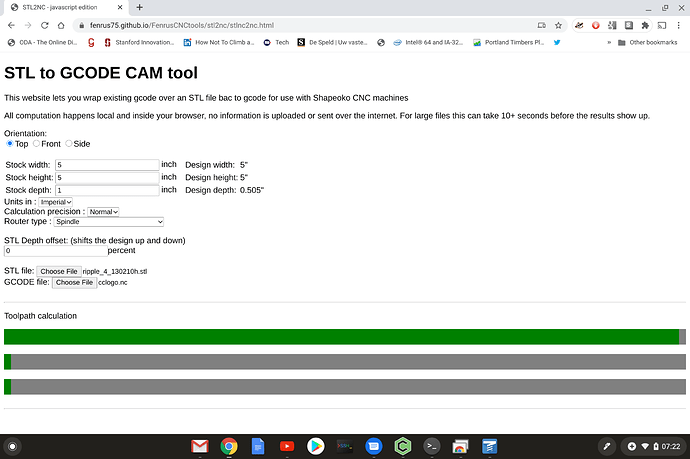

Step 2: Basic 3D cut from a STL file

Grab an STL from thingiverse (https://www.thingiverse.com/thing:50851), add spindle support to gcode converter, convert to gcode (https://fenrus75.github.io/FenrusCNCtools/stl2nc/stl2nc.html of course) and cut out of 5x5 basewood, while cheaping on time with a 1/8" bit and too big stepover. Bad mistake. Basewood is too stringly to get nice 3D cuts… but that is for next time

Gcode: ripple_4_130210h.stl (1).nc (2.0 MB)

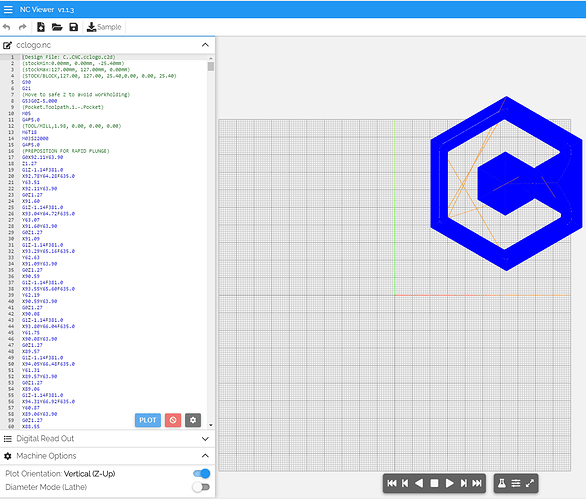

Step 3: it’s Friday night

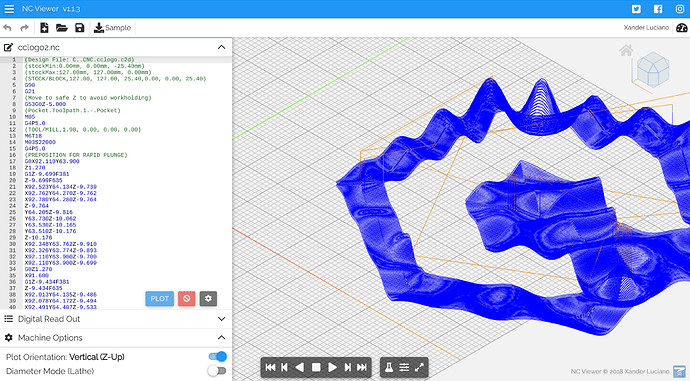

So it’s Friday night, and I’m sure everyone else by now is also asking themselves: This was boring. Can we cut the 2D gcode from step 1 right on top of these 3D ripples?

(well maybe you don’t. But I did. It’s been a long week at work)

The answer is: Yes you can. Maybe you shouldn’t, but you can.

All kidding aside, in 3D vector tool path @ads wondered if one could use 2D toolpaths to cut roads into 3D landscapes and well, yes you should be able to.

It’s just a matter of modulating the Z elements of the Gcode to the underlying 3D model (bla bla more digital software gunk here).

For example, the gcode from step 1 above, after modulation, looks like this: cclogo2.nc (2.5 MB)

This will work for any STL file, overlaying any gcode that carbide create will generate…

looks like it is following the ripples perfect!

looks like it is following the ripples perfect!