…but I bought a stack of blanks and I need to use them.

Also, I was inspired by @fenrus’s two-color epoxy so I figured I would try three colors (spoiler alert: I messed up the amount of dye and ended up with two of the three colors looking exactly the same  )

)

Also, I can’t get enough of using my 25° single flute vbit.

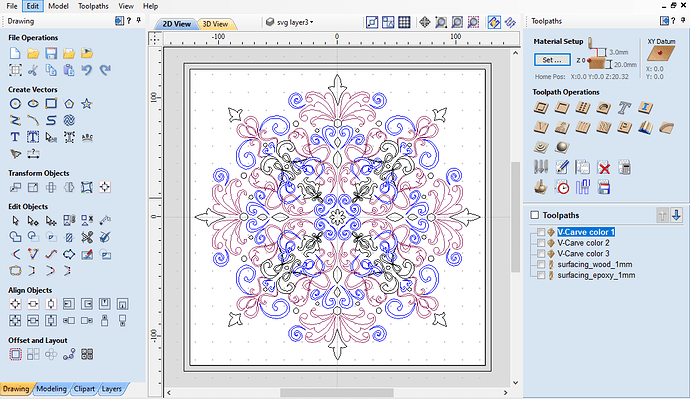

So I started from a vector design (Etsy to the rescue again) and imported it in VCarve, which has a nice option for using Layers in the design, and assigning one display color to each layer, which turned out to be very convenient to “preview” what the final piece could look like:

I picked three colors from the box’o’dyes

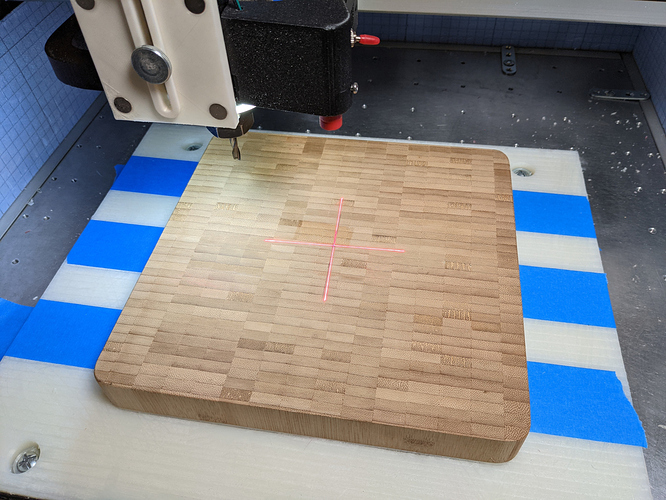

and installed the blank (well, the perfectly good 25$ trivet from Habitat I was about to mill for fun). By the way, after a few days of use it seems like the laser cross-hair for X/Y zeroing is convenient enough that it will stay on my machine

I surfaced ~0.5mm off the top of the blank,

and proceeded with the first v-carve op:

Sealed the bamboo with clear epoxy, let it dry, and poured the first color:

This below is what happens when one is impatient and does not let the epoxy fully cure: chips that are bordeline stringy

Good enough, I left about 0.2mm of epoxy before running v-carve #2,

then poured color #2,

and surfaced that again,

before running v-carve #3:

and proceeding with the final pour, which I later surfaced removing epoxy down to bamboo surface level.

One thing I did not like from my previous trivets using the same blank, is that it’s too HEAVY. I decided to remove some of the material from the bottom.

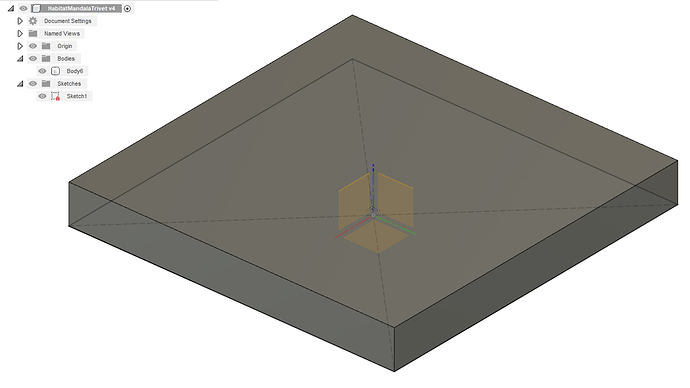

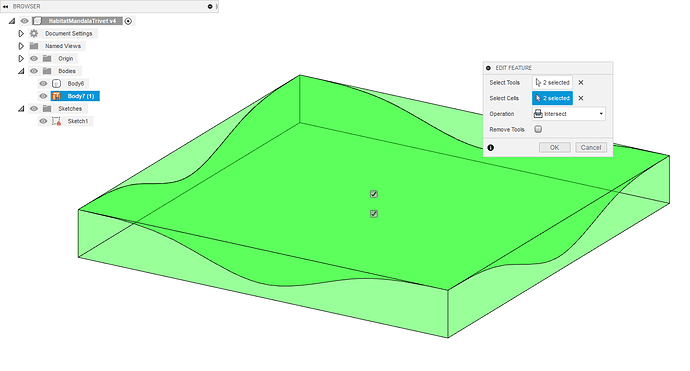

Fired up Fusion and drew a box a little larger than the trivet dimensions,

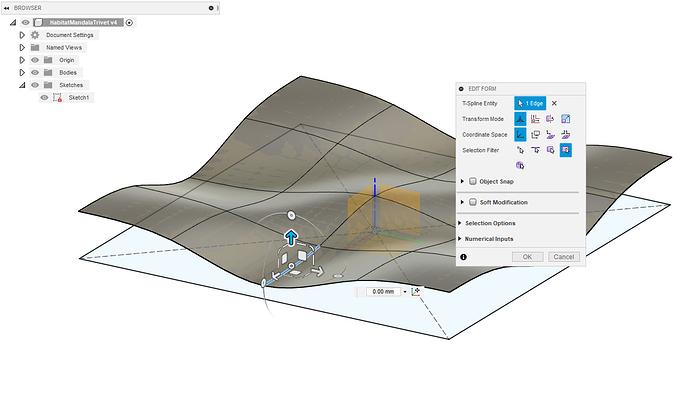

Then created a plane Form, and used the “Edit Form” to push on four of the edges, to create a wavy surface:

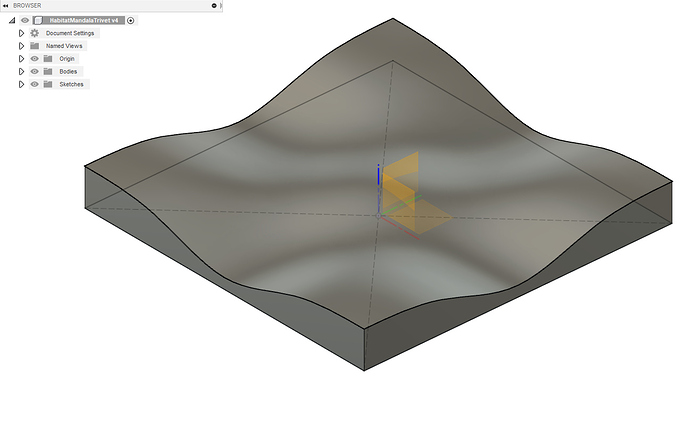

Then used the (awesome!) Boundary Fill feature to intersect the box with the surface,

to get to the final shape:

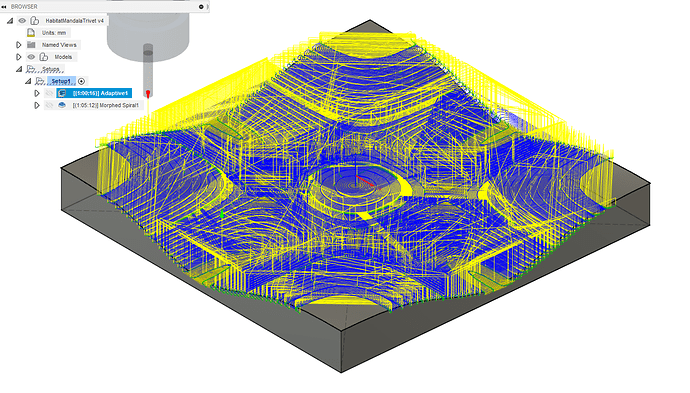

I created a 3d (adaptive) roughing toolpath for a 6mm square endmill, 24k RPM, 120ipm, 0.8mm optimal load

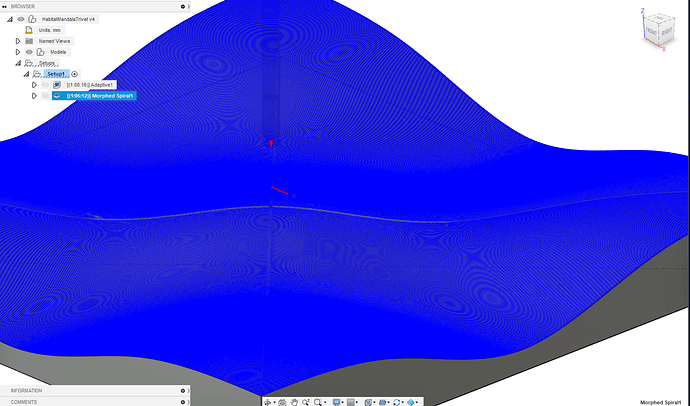

followed by a morphed spiral finishing toolpath using a 1/4" ballnose endmill (Carbide3D’s #202), 0.5mm stepover

(funky Moiré effects in that rendering!)

Roughing ran fine,

and finishing as well (I could have bumped feedrate significantly)

A little manual sanding brought the surface to a nice smooth finish,

Et voilà:

So, multi-color epoxy inlays are easy and fun, but…this NEEDS to be background project done in parallel with something else, because the multiple curing times add up to almost a week to complete the project.

I can’t even promise this will be my last trivet, I have three more of these blanks looking at me from the back of the garage.