How long did that take? I like the aesthetics of the grain.

way too long, as it was a trial project.

3D rough 0.25 flat = 13 minutes

3D finish 1st tool = 0.125 ball nose 9 minutes (x3 angles)

2nd tool = 0.063 ball 33 minutes per path (x3 angles)

3rd tool = 1mm ball 65 minutes per pass (x3 angles)

4th tool = 0.5mm ball 114 minutes per pass (x3 angles)

I ran most tools at Shapeoko Softwood defaults.

The 0.5mm I set at 0.009" stepover zero depth and 32 inches per minute.

Basically, I spent two days messing with it.

I think it was a total of 18 finishing passes.

I restarted a lot of passes dialing in where I wanted the base zero.

The wood warped and I re-ran all 0.5mm finishing passes, then re ran all three 0.5mm passes again just to clean the project.

I was trying to find a limit with bit size and wood… 0.5mm is not the limit.

Also, Good Job to the people at Carbide3d. The machine showed exact repeatability and no error maintaining the Z zero.

fwiw, I set the feed speed to 32 IPM as it seems faster would cause Z issues.

That’s very insightful. Thank you for the breakdown. I need to carve out some time to give it a go.

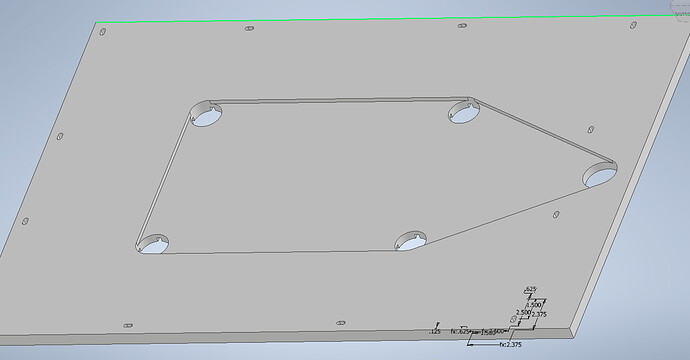

I am making my own design, but I think I actually messed it up a bit. For some dumb reason I made small air channels going to each opening for the vacuum to pull. Also, to make matters worse, I have already glued the two sheets of MDF together thus making alterations much more difficult. I am thinking about separating it as much as possible and milling out a giant pocket for increased airflow. See the photo.

I have seen vacuum boards with raised squares that they place rubber tubing in the slots the size of their project.

Similar to this but not as deep to fit the tubing.

This one looks to be sealing the MDF.

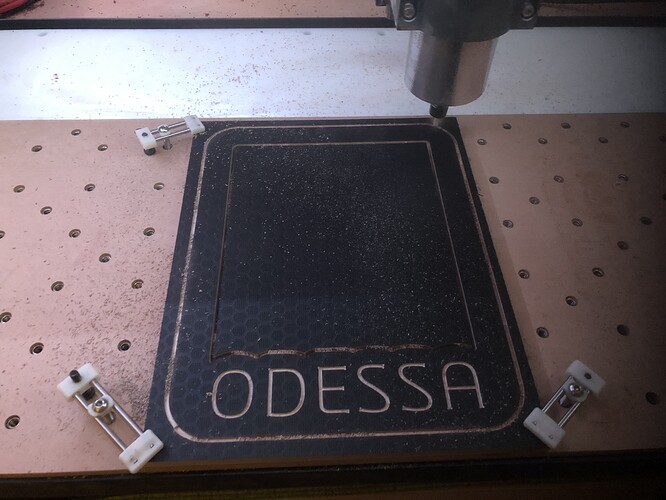

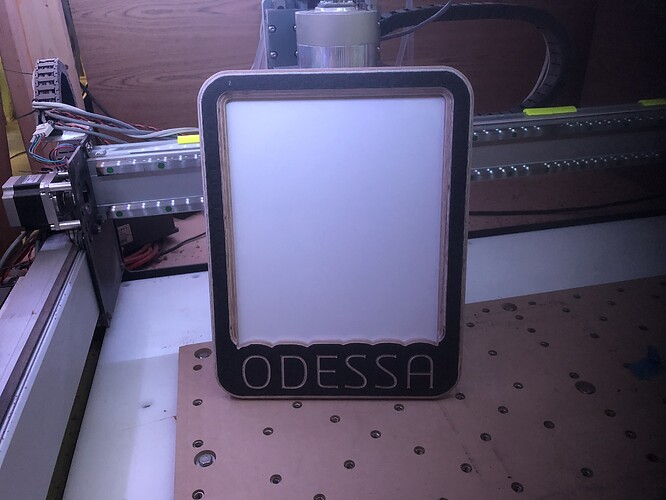

Thanks, Jeff! Not quite tied to any geographical location purposely, my youngest daughter’s name will probably have people guessing why we chose that name for the span of her life.

She may well be a topic of discussion - I would certainly reinforce with her the ancient Greek city in Ukraine as the preferred etymology… rather than the one from the Frederick Forsyth novel, that is!

Haha! Gerry - had I been more into the fictional thriller genre, I would have avoided the acronym.

I personally like unusual names out of the norm. It’s beautiful.

I just finished a cutting board project today. It all started with a low cost bamboo cutting board from the local big box store. I then added my own epoxy filled embellishments.

I got a gift basket for fathers day and inside was a small bamboo cutting board. Now I will put US Space Force logo on it and give it to my AirForce veteran grandson. He worked on B-52s at Minot but likes the SF.

Great idea!

Today’s project was a sign for someone’s 50th birthday and also this year is apparently the 50th anniversary of the opening of Disney World. The images I could find of the castle were either too detailed or not enough. This is what I could find to fit in the time frame that the person required.

The sign is about 15 inches by 21 inches cut on my Shapeoko 3 XL and it was pre-stained with Saman Blue water based stain. Started the poly coat just a few minutes ago. The sets of holes on the bottom are for four hooks to hold keys for them. The wood was ash.

While this one almost hit the limits on my Shapeoko for size it has definitely hit the limits of my band saw for cutting it out from tabs. Kept running into the side of the saw. Going to have to be more careful about tab placement in the future.

I also had some issues with the cutter disconnecting while doing the cut out and had to keep restarting. I am so glad it kept the zeros and was able to start in the right spot after exporting a new NC file with just the cutout tool path and having it start the cut again from the last depth. It probably disconnected 8-10 times and I had to keep redoing the last tool path. Rebooted the computer after the job was finally finished, cleaned the machine checked for loose screws and belts, loose connections etc and couldn’t find anything. Seemed to run fine on the cribbage board I did after it today without any disconnections. Hope that was a one off and I don’t see that happen too often.

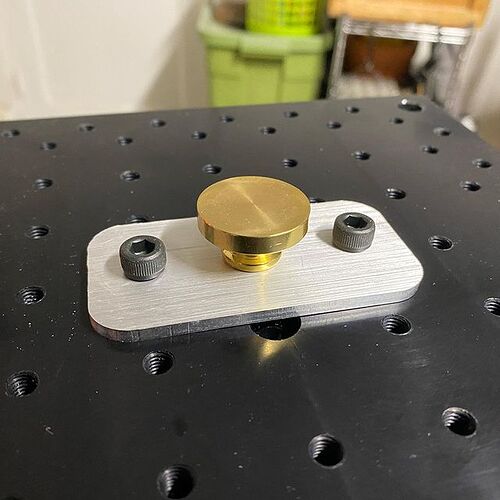

If you do not look at the contest topic here is what I ran today.

First time milling aluminum.

I made a little fixture plate to securely hold a wax seal blank while engraving.

2x M6 holes for the threaded table and 1x M8 hole for a set screw.

Didn’t come out perfect (edges are a bit weird) but works for what I need for now.

Drill/bore and tap or thread mill?

Bore and tap.

Would like to try threadmilling at some point after I get more comfortable with aluminum.

I dont know what you said but your stuff is beautiful. Very cool technique. Are the wooden parts hollow or blocked or are they solid wood blocks? The top one looks like a tree stump but the bottom one looks like boards joined together. Nice work.