I think I will do this same thing. Thanks for the inspiration

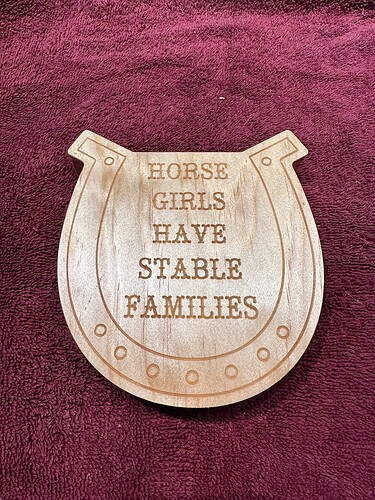

I had a 2 AM idea for “Horse Girls Have Stable Families”, so I found a horseshoe .svg and got to cutting!

It’ll make good coasters, potholders, and possibly mini signs.

The #302 V-bit makes such lovely lettering.

I love it. I have a horse girl too!

I made a sign for the barn and am working on some coasters for all the girls.

With the mannequin on it you can call it art. Call it the THINKER or Contemplating Life.

I did a quick engraving job this afternoon for a local Motocross racer. Team name and rider number on a Rekluse clutch cover.

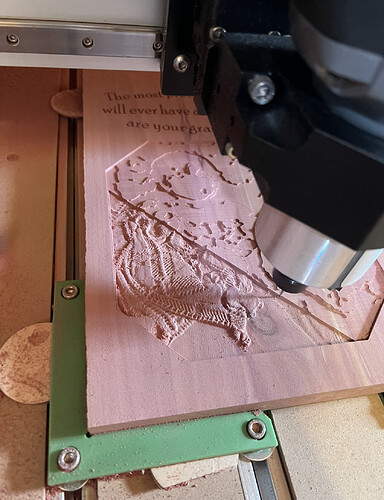

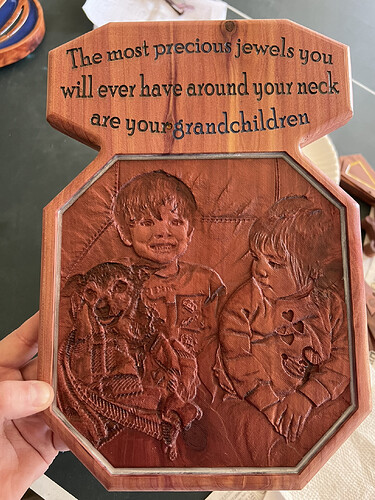

Finally tried my first photograph. Used one of my niece and nephew and I was very happy it turned out recognizable!

I don’t even mind the striation effect on this one, although next time I’ll follow the sound advice of a second perpendicular finish minimizing step over. She was elated and I suppose that’s what matters in the end.

This was the original photo for reference. I made it grayscale in Inkscape and imported in CC.

Wow! That turned out great! What software did you use for that?

Cut four more cabriolet legs, scaled longer and a bit more narrow than the earlier ones for a coffee table (see above).

These, plus 4 more are for two end tables to compliment the coffee table.

Still rather more hand work then I’d like, I’ll be really tired of knuckle sanding by the end of the day! The next set I will try tweaking the tool paths a bit, maybe use 1/8” ball nose for final finish. These were cut 100% with a 1/4” ballnose.

The stl for the legs was not the best but it was free. Plus, truth be told, I doubt the finished product will be scrutinized by others to the degree I do. But, I’ll still put some more work into the stained piece anyway.

Fun stuff though.

Thanks! Just the free program Inkscape. Nice and simple just clicked fliters → color → greyscale. Then the import option on Carbide Create in the model tab.

Really nice work. Are you using a 4th axis to carve those, or doing creative flipping on the cnc bed?

Creative flipping or 4 sided machining, whatever your preference. Requires that your blank be perfectly square and x,y repeatable. Otherwise, not particularly difficult.

Is it a matter of hosting or is the information gone? If the data is available and just a matter of hosting, let me know, I can help. If the info is gone (deleted/not backed up) that’s a bummer. ![]()

The hosting went away, and it was felt that it wasn’t worth bringing back in the state it was in — possibly because it had been perverted by my using it as a personal notebook.

For folks who want access to it as it was, it’s on the Wayback Machine:

http://web.archive.org/web/20201111182925/https://wiki.shapeoko.com/index.php/Main_Page

and pages have been going back up on an as-needed basis at:

That said, it was getting problematic trying to juggle information for 3 different machine versions, and there are a lot of much better resources now such as:

and of course, everything which one needs to know ought to be at:

If there’s some specific information which is needed, either from the wiki or the old forum, let me know and I’ll try to look it up.

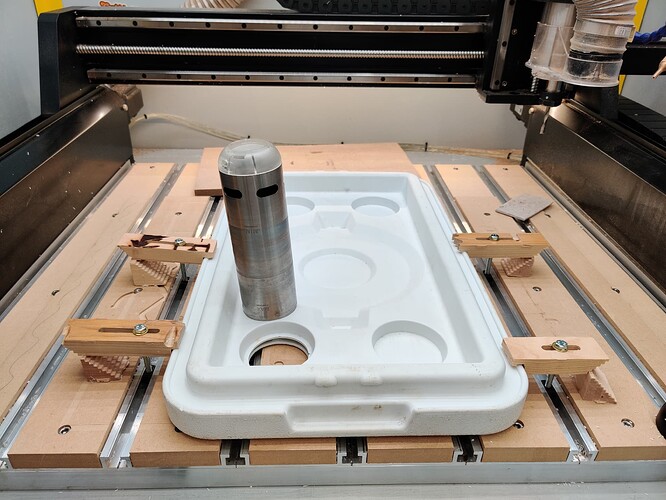

Here I am using one precision machine to make another precision machine better!

I picked up a cooler at a garage sale and had to mill a large hole in it to make the ANOVA sous vide fit. It fit perfectly on the fit try.

This has got to be one of the oddest things I’ve milled yet.

Hey John, good to hear from you again, long time.

What sort of critter are you going to sous vide in an ice chest? Where did you find a bag that big?

Interesting use of a cooler but with Sous Vide be very careful about what bags you use for cooking in. There are some very nasty chemicals that leach from the plastic into the food epically when being heated.

Thanks @Griff, it’s good to start being back and posting more again. Health issues have made workshop time limited over the last many months and they are hopefully remedied now.

This setup was used to sous vide a 10lb brisket and some ribs at the same time. It’s both lets me cook large items but also many items and more efficiently with the insulation than with a pot or other plastic vessel.

Thanks @Able for the advice. I use vacuum sealer bags meant for this purpose that are primarily polyethylene and an ethylene vinyl acetate layer for heat-sealability so they are safe. It’s nice having an FTIR at work!

Ok, was just curious as I see lots of references to the wiki in post here. ![]()

Nothing too fancy but prototyping palm size bottle openers which requires too sided milling, have my toolpaths down to about 30 minutes with tool changes but once I’m happy with the product I’ll batch them 10 at a time which should cut down on time to mill. I intend to have multiple sayings/graphics for the top side (Beer Call, Pop a Top, Hoping Good Times, Key to Happiness,…) or clients could personalize the top if they want. I find the one with the graphic on top looks better but had to compromise look for feel in the hand as if it doesn’t feel good in the hand people will not want to buy it.

Pop a top again (Country Twang Voice).