Just saw this on a bike ride, it reminded me of your post….

I like it. Pre fertilized.

I think with how well the flowers are growing that might be post fertilized.

Those are some real sh#t flowers ![]()

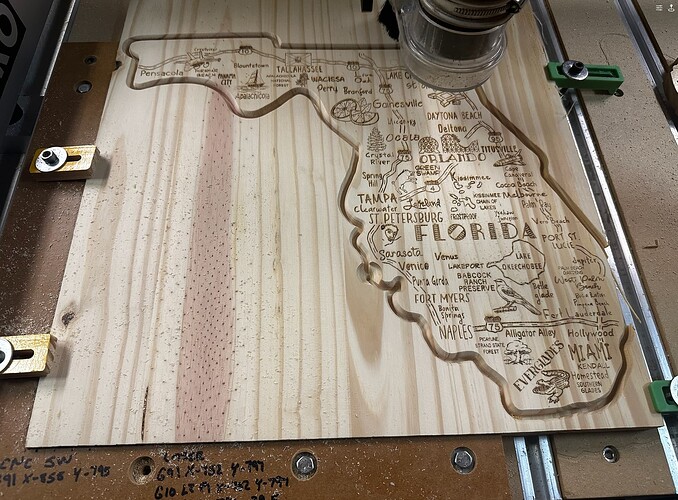

Another big tiling job on the S5Pro. Now that some people I’ve done work for in the past, know I can process a whole sheet, guess what they’re having me do. ![]()

I’m really liking how the tiling in CCPro works. Simple to use and both of the jobs I’ve done lined up really well.

Nice job maximizing your material there.

Your machine looks to be up against the wall. I assume you rolled it forward to do the bottom of the trees and then back to do the tops?

I want to try tiling but don’t want to pull the machine forward or turn it 90 for some tests. I was thinking I could just use a smaller piece and define the tile size pretty small. That way I can make sure I understand the process. Would that work?

You’re correct in how my machine is. The table is on double locking casters and I just move it forward and run the job. I anticipated doing more tile jobs, so I made sure everything was set up for it. A smaller tile length might help with the amount that would overhang, but the extra moves and areas for me to mess up, don’t seem worth it. But your situation may be different.

The smaller tile idea was really just so that I understand the process. If I get into doing it in any big way I will rearrange things in my shop. For an occasional run I would just slide forward like you did. I have retractable casters on my table.

Your idea is exactly what @KevBarn14 suggests in one of C3D’s YouTube videos. Practice in a smaller one first. ![]()

The wife wanted a place to put mail on her bakers rack. One scrap piece of wood later and she’s got a minimum viable product.

I wanted the mail to fall back towards the rack which means I need to cut at an angle…if you can’t angle the head, angle the workpiece ![]()

(It’s bolted through the rack to some ez-lock inserts)

Happy wife, Happy Life!

Cuz if the wife ain’t happy ain’t nobody happy.

![]()

![]()

![]()

Combining the power of laser and CNC into one machine. Love this functionality. Makes swapping between to super easy and now endless possibilities on projects.

Also finally learned how setup and use a roundover bit. Productive weekend.

Semper Fi! I was thinking about doing these for my platoon for the Marine Corps ball this year. Would you be willing to share your svg file?

Semper Fi brother! If you cannot get his file,i have one similar that could easily be modified somewhere on my computer. Happy to share if youd like.

Tiled Topographic map for a retirement gift. The retiree worked for the Portland district of USACE and on the back of each tile are engravings for each project they completed in that area. Tiles are attached via magnets so they can be pulled out and examined.

That’d be great! I’d really appreciate it.

Looks great. Did you use Vectric for the CNC and laser work or did you use Lightburn for the laser and then Vectric or CC for CNC work?

No worries. Ill get back down to the shop tonight or tomorrow morning im sure.

Tried my hand at epoxy, making a sign for a friend’s barn. Learned a lot, and it took me back to when I was a screen printer. Hope to do more of these. The sapele was nicely hard so cut well, but the pores were challenging. Long term I want to build a PID controlled hot box; this project locked up my cnc for so long.

I looked at the picture before I read your post. I thought it was Sapele is a beautiful wood. I made two end tables out of sapele and it is amazing to work with. Not all but most sapele has the chatoyance but luckily most does.

Nice carving and nice flower. How did you get the black veins in the flower?