Harbor freight Tools has a nice 11-v polwerd chain saw that works well and is cheap if you have access to 110v- they also have a 20v batter configure

Rxman

I wound up buying an Oregon 18" bar 120v from Amazon. I have used it a couple of times and it is very handy. Thursday I cut a piece of oak that was the very bottom of a 12" tree and cut the knobs off where the roots plunge into the ground. I put some AnchorSeal2 on the exposed parts. I had already put the Anchorseal2 on the top and bottom top keep it from cracking.

I just got a new to me Jet 1642EVS lathe and the tree was cut down to make way for my nephew’s wife that has passed away from cancer. I plan to cut the 3 blanks I got rough and let them dry and then finish turn them as a remembrance for her mother and my nephew. I plan on making a flat bottom and use my Shapeoko to engrave a memorial on the bottom. I got 3 because sometimes green wood will crack or warp so bad you cannot finish it. I will rough turn them once the weather warms back up a little and put them in a paper bag with the wood chips. When I put it in the bag I weigh the piece and put a tag on it. Every month or so I weigh the bowl blank and when it stops losing weight it is ready to finish turning. Then I will engrave it in a circle.

Since dogs technically have no thumbs, how did the dog cut the log up?

Hi Dave,

It looks great… Do you mind to share the plans or more pictures.

Thank you. Wasn’t much of a plan going in, just working with what I had on hand. I can take more pictures though.

That’s will be great… Thank you

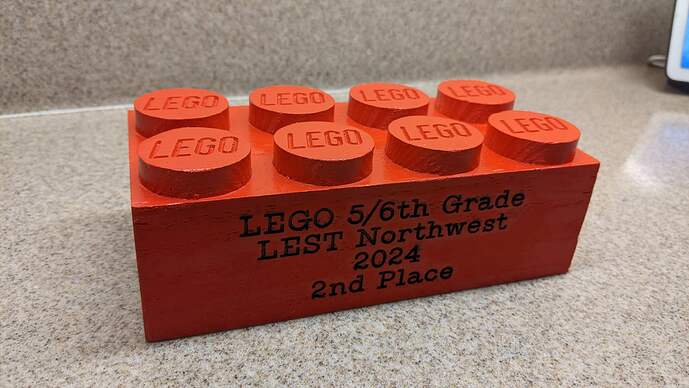

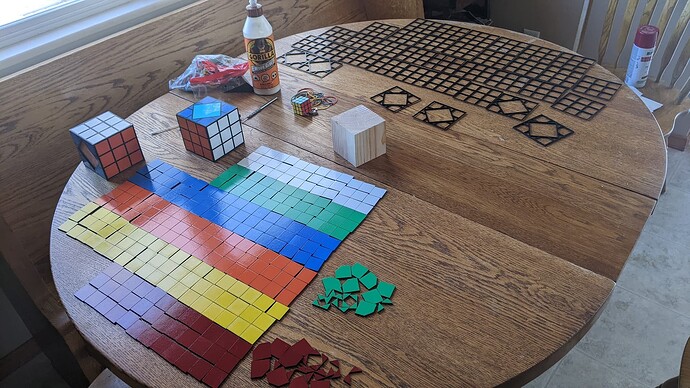

I recently completed a bunch (100 awards) for a tournament that our school participates at. This is my second year making plaques for the tournament. There were several new categories - LEGO and Cubing. I had fun challenging myself with coming up with a something different than a traditional plaque.

With the cube, I leaned heavily on the JTech 44W laser attachment I have to create the cubes.

Nice. How did you do the lettering on the plaques? Paint, epoxy, laser?

I just made 22 for Boy Scouts and about to

Make 25 for the lions club. I am just using danish oil in the carve to make it stand out. The guy with the scouts preferred the carved look which was fine with me because doing epoxy on that many would be a pain.

I considered on the others doing the carve, painting and then sanding off surface. It has a lot of very fine detail. I did a test with just the oil and like it. It’s fast and easy but I like the crisp lines you have as well.

On the LEGO block I used my 14 W laser. With the red and white blocks I kept the dark burn, but on the blue block I wiped in white acrylic paint which worked ok. I didn’t carve the lettering because it was a soft wood (4x4 post) and the small lettering would be prone to chip out. With the Cubing awards, I purchased different colored thin aluminum business cards and engraved with the laser on the card. Cut the card to approximate size needed, glued on the laser cut square (which I sanded down so later on things would be flush), once glued cured I sanded the aluminum to the same size as the wood it was glued on.

As stated before, it’s basically a drawer with a second drawer that pulled out sideways from under the first one. I’ve seen a few different ways of building it, but this works for me. I attach a piece of 1x4 under the first drawer slide to hang the 2nd sliders under. In this case, the laptop slide out is on 20" slides, and the mouse slide out is on 12" slides. Hope this helps smohd.

Great job on the awards; love the way the lego and cubing awards came out. The standard flat pieces are so over done, great to see the multi-dimensional approach.

Nice setup. What do you have on top of each “drawer”. I bought some 18" x 18" carpet squares a while back and use the when I want something to line a space and not break the bank. I still have about 20 of them left. The carpet squares have a low knap that is a loop so it is akin to Berber carpet.

Carpet squares are a good idea, I’ve seen them on clearance at the local lumber yard before. I think they were changing stock or something. For these shelves, I had some left over wall board from remodeling the interior of our camper last summer. Nice smooth surface, fairly resistant surface to moisture, and looks nice.

Thank you Dave I appreciate it…

I am NOT going to show my wife this !

Very cool. What is it?

It is a Metmo Driver

You got in the wayback machine with Sherman & Peabody ![]()

I had one of these, and used it.

Still have one of these, but it sits on a window sill as a decoration

My first introduction to the Spiral Ratchet Screw Driver was unpleasant. I had never seen one before and some genius had stored it in the compressed state. I was looking it over and triggered the release. Damn thing sprung forth and hit me right in the forehead. Thank goodness no one saw it and thank goodness it didn’t have a bit in it.

I considered getting everything out for a photo session, but that seemed like a lot — hopefully a simple enumeration (with links where appropriate) will work:

- Schroeder ratcheting spiral screwdriver — bought it new from Sears back when they still carried tools:

it’s in my “Frequently Used Tool Roll”:

https://www.reddit.com/r/toolporn/comments/9i1wzq/frequently_used_tool_roll_4096x2304_oc/

- Bridge City Tool Works PB-2 Palm Brace:

(I also have a Stanley of my father-in-law — for some reason he still had it, but no bits, and I’d lucked into a set of bits in a picked over tool chest I found on Craigslist)

- Millers Falls No. 2 double-pinion “eggbeater” hand drill (3rd type):

- Lee Valley replica eggbeater drill:

and of course, the afore-mentioned Metmo Driver, and I am waiting on a stainless steel “Pocket Driver” from their recent Kickstarter:

https://www.kickstarter.com/projects/metmo/metmo-pocket-driver

Now if everyone will excuse me, I need to get back to writing a book…