Nice design rimming the ports to keep slop contained. My dog is a sloppy drinker too, he laps against the edge of the bowl which I guess is more efficient for him, more messy for me.

My son-inlaw gave me a board to carve for the back of his bar, he did the finish (oak floor boards charred- mostly flat ![]() ) Then I carved it.

) Then I carved it.

Pretty happy how the carve came out,

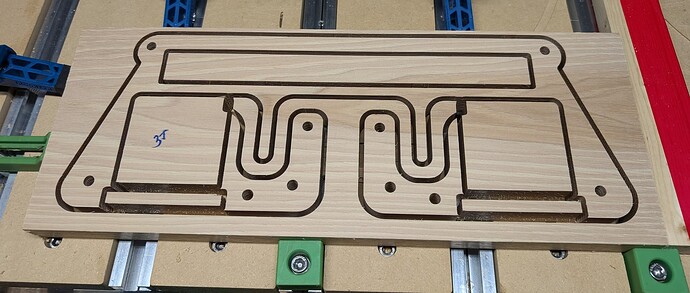

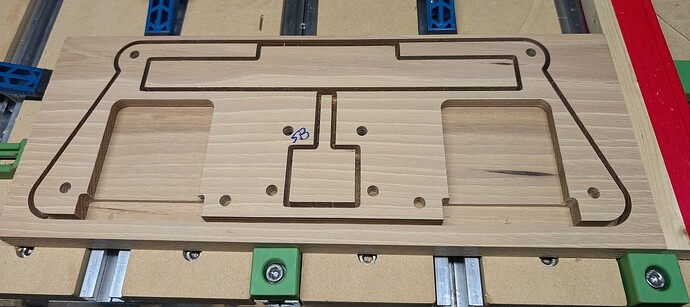

My nephew gave me some pieces of wood used for shipping spacers. The peices are about 1.25"x1.25"x15" in size. I assembled the spacers into a board and then used my Shapeoko 3XXL to cut out a change tray. The slots in the tray hold a full roll of the specified coins.

This I absolutely adore! Where did you pick up the MP3/FM module?

I got it from parts-express.com.

wow, thats impressive. any chance you’d share that file? It very cool.

Lol my son has been bugging me to make him some speakers. These look amazing!

Thanks.

The file is for Vectric if you use that?

Thanks Graham, don’t know what that means, but figured it out.

Thanks! I had a lot of fun building this.

Nice - organization and efficiency.

First MDF cut yesterday.

This is a picture of my grand daughter, daughter and wife coming off the ice after a practice hockey game. Awesome. No I don’t skate never mind hockey.

Easy cutting. I used the Zinsser Sanding sealer between cuts.

Fusion for the CAM generation.

Used Image2Surface free add-in to import image for mesh generation.

1/4 end mill (#201) for a Contour and Parallel cuts.

DOC 0.1 , stepover .08, 10000K rpm, 70 in per minute speed.

Left 0.008 of stock

1/16 ball mill ( #111) with a Scallop path.

Stepover 0.003, 10000k rpm, 45 in per minute speed.

What font did you use for the lettering?

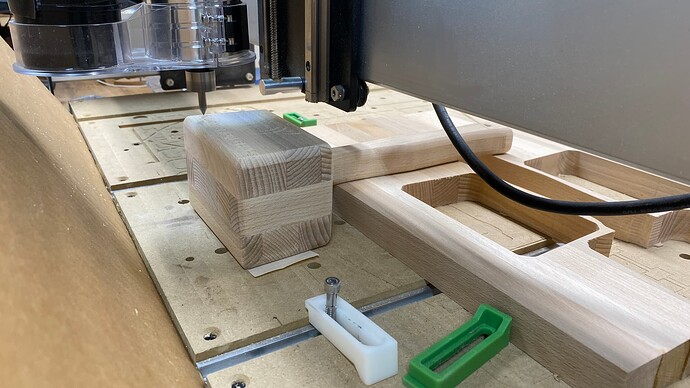

Working on a control panel so I can have a touch screen and Raspberry Pi for controlling my Shapeoko. Switches will be for the router, vacuum, lights and fans. Looking forward to some nice tactile clicking when operating the machine!

Forgive the incorrect pocket holes - I got over enthusiastic with the drill and will cover them later on ![]()

Using the same shipping spacer wood scraps that I used for the change tray, I made a mallet for the shop. After assembling the mallet, I decided to gift it to my nephew (the source of the scrap wood). So, I used double sided to secure the mallet back into the 3XXL and added some engraved features. Hehe, there was not much clearance for the engraving function. I am making another one with a bottle opener in the pommel.

Oh, I forgot to mention that the mallet was a modified version of @WillAdams example in CutRocket.

To expand on that, I believe it’s this mallet design:

by @wmoy

and a decorative design which I worked up at:

and I will further note that it is absolutely perfect that the mallet is decorated thus.

For even more such see: