Oh great, another side-project distraction. My wife is going to block be from this forum. LOL

Hey it looks cold outside your window. Today we got to 57. Now for people that live around snow that is not cold but here in Texas it is cold. It has been getting around freezing at night and my shop heater is working overtime. I glued up some rings for a segmented project today. It will be a Dungeons and Dragons Dice Tower. Hope the glue sets properly. I think the glue will work down to about 50 degrees. I will be making a court yard at the base of the tower and am going to use SO3 to make an inlay with the person’s initials.

This is some leftover South American Walnut and I still need to figure out the platform for the dice to roll down.

I will not be making a lot of presents this year. This is one for a Birthday on the 23 December. Need to get to turning to get in the mail by the deadline.

Day 2 of honest use, plenty more to learn and glad I picked up 1/64 endmill (this was done with 1/32 - 121, 122 primarily). Enjoying the journey

This place will blow your mind (and very well could get a spouse ban.) Yer welcome!

That looks dangerous … Hmmmm

Thanks !

It’s a pretty cool store, then my wife bookmarked it ![]() and added another project to the mile long list she already has.

and added another project to the mile long list she already has.

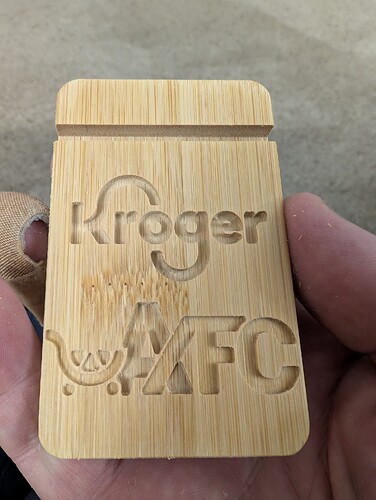

Another day, another custom creation (Day 7 since assembly and day 3 of cutting - spindle did not arrive with machine). I call it a badge/picture/card holder and its no bigger than a credit card. (I am an IT Leader for Associate Experience Foundation Capabilities or AXFC).

That sounds like my wife! We were at a sawmill looking at slabs. She kept adding more slabs to my pile with all kinds of ideas she wants done. ![]()

That’s unreal man. Super cool!

I lived in Texas near Austin for a bit, but this has always been home. The high was 0, low of -16 when I did that on Wednesday. Too early in the year, but nothing we aren’t used to in northern Minnesota.

Here’s the inverse of the La Catrina I posted awhile ago. I tried it in black substrate but the colored epoxy didn’t show well. Here I laminated black polyester sheet to white and drum sanded until the black layer was 1.1 mm thick so that it would be exposed when milled. Simple and fun process, new to me, mill and fill with colored epoxy. Repeat with next set of non-contiguous colors.

That looks brilliant. Will the rings turn?

Yep, the rings will spin and be magnetically held in and indexed. Should be pretty sweet…might need to get a gold plating setup to really make this type of work pop ![]()

I wanted to use up a little piece of Purple Heart and play with some mixed media this weekend. The mother in law runs a dog grooming business, I put this together in a one day build so some choices were made with that in mind…

Lots of room for improvement but it’s not bad given the time and material constraints.

Purple Heart wood engraved on the nomad 3. 0.1mm copper clad laser cut and set in the engraving (could use v-bit but I wanted to practice cutting on the laser).

Brass bars are solid, 1/4” for the bent pieces, 1/2” for the large bar.

Bent bars are threaded on the wood side. They thread into an EZ-lock threaded insert in the backside of the wood.

Large bar is interference fit to the smaller bent bars.

(Sign says “ruff” in a terrible font…but that’s what she chose so🤷♂️)

Lessons learned:

Bending things consistently is trickier than expected.

The copper sheet is a huge pain to cut with a 60w fiber laser, v-bit will be interesting to try instead.

“Hammering” copper gives a more interesting texture than expected. It’s smoother looking in person than in the photos.

My finishing game for wood is pretty weak. I don’t even have an orbital sander ![]()

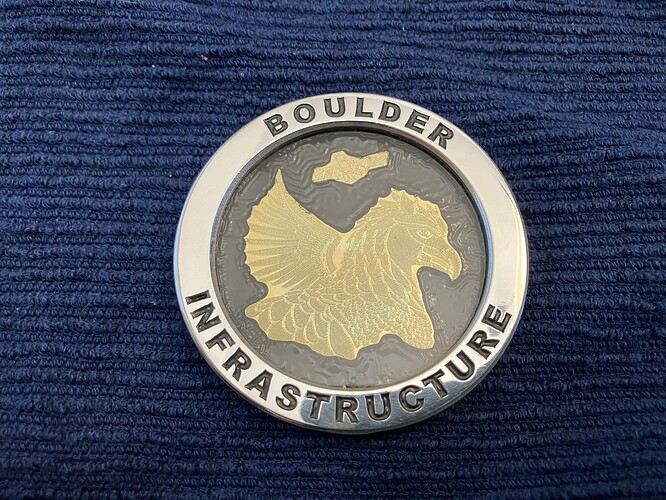

Been working on some challenge coins the last couple of weeks. It was my first real foray into CNCing metal which was has been fun. Broke a few end mills dialing in speeds and feeds and testing different designs. Ended up going with a bit of a non-traditional design using aluminum, brass, and glass but I’m pretty happy with the result. Overall, it was a fun project and I learned a ton doing it.

impressive! very impressive!

Oh that’s cool. I’d love to see the process for how you did that.