You did all the shaping on the CNC? These are beautiful.

Yes, this was the earlier post with more details on that.

Nice! Nice! So many questions but I’ll just ask one…what bit were you using for the center panel? That’s usually created with a shaper. Were you using a shaper bit or something smaller with multiple passes (I feel like this is a noob question, but there it is).

Really nice job on the stand, especially set up to be flat packed for shipping. Lots of folks could use these!

CullenS machined the profile out on the cnc and looks really good. I would be hard pressed to realize it without me seeing it in person. His project has inspired several of my own I plan on completing one of these days.

Why don’t you cut the miters on the cnc? Make a jig to hold the stock, set a stop at 58” off one end of the cnc bed, set a tool path at 45 deg and mirror it for the opposite corners. I’m not sure this makes sense without illustrating it. Sorry.

One of the most important things for tight miters is to ensure the stiles and rails are dead equal in length and obviously a true 45 deg miter.

I use #201 as a roughing bit and then #202 as a finishing one. Used the molding toolpath in Vectric.

I used to have a shaper but gave it up many many years ago as it was underutilized. It took about 40 minutes per panel not counting the rails/stiles, so a shaper would have been much quicker but would have had to have the right knife for it.

I could do that, it would certainly take longer, but precision is more important for this job. I could machine a sled in place with a pocket to align the material. That way I can be sure of a 45.

The main profile on those pieces is going to be done by a millwork shop given the quantity and size. I will cut a rabbet on the back and then the miters and glue to a backplane. I used biscuits on those small cabinet doors. In this case I could machine something on the backside to help lock the pieces in place. Ooh, another jig maybe. Put the mating pieces in at the 45 and machine a pocket for the locking key in both at the same time to insure proper alignment.

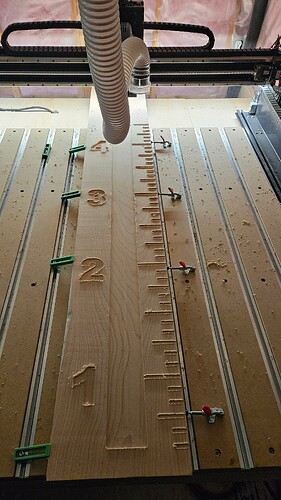

I have executed my first ever larger then work area project with success.

I have a 4x4 and my project was 82"

Some careful planning and things went very well.

My obstacle being that the original board wasnt straight either.

The middle of the board has a pocket for writing.

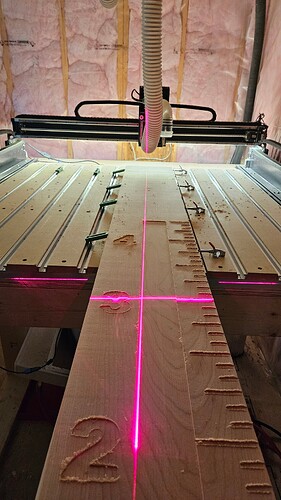

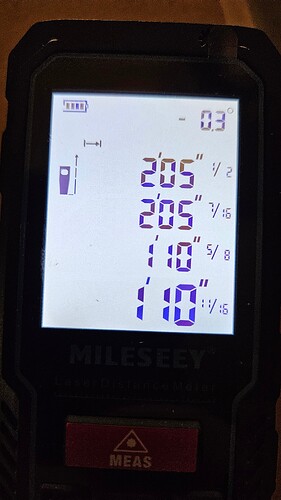

When i matched up the board the second time i made this pocket .025" thinner on each side. This allowed for any mistake to be viewed and then calculated to fix. I used lasers and elecronic measuring device to get me to 1/16"

There may be easier ways but this was super fun and made me think.

That would ensure good alignment on the miters. What is the width of material for the frames? The wider the material dictates tighter tolerances on miter joints as I learned the hard way many, many years ago…

They boards will be 3” wide. I will have to see how far back I can get them on the machine and still have the other end poking off. Of course that will necessitate movement of a bunch of junk in the garage.

Interesting space allocation on the back side of the cnc table, alignment process and final result is outstanding.

Here is an unconventional usage of a CNC for making face frames.

It seems like more work than it is worth but I guess if you have a lot of varying lengths to deal with it may save time.

Interesting setup for, thanks for the link.

Love this project and it’s high on my list to make one of these. Just curious how the routed and unfinished slot will be used?

Nice work!

I’m guessing some sort of white board or chalk board type insert to mark on?

Thank you!

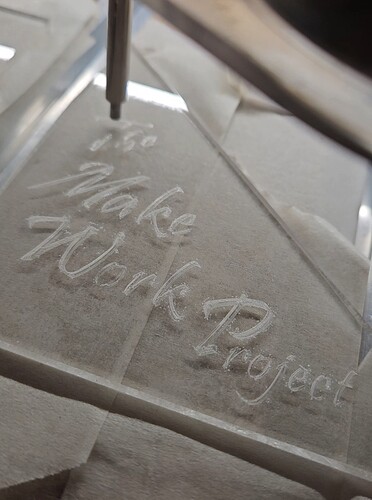

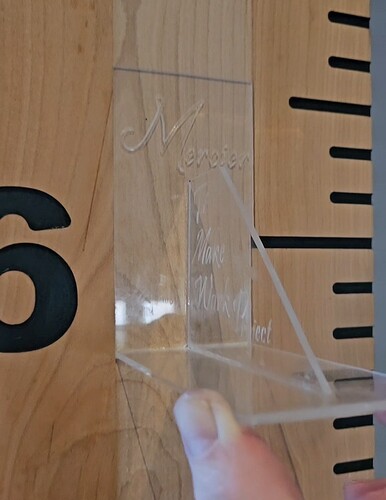

The unfinished slot is where they will record all of their heights. Easier to write on unfinished wood was my thinking. The pocket also lead to an aditional idea of a sliding ‘ruler™’ that would help you mark the head height

The family name to match the board on the face and my company name on the brace.

Coolness level-up with the sliding rule!!! Awesome!

Great idea on the sliding measure marker!