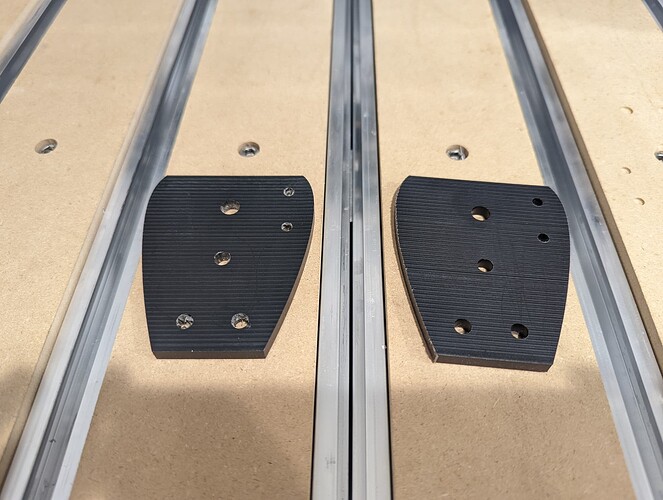

Got to do my first cuts on the HDM today. Cut some UHMW parts for my 3lb battlebot and started an aluminum sign with my logo. It cuts like butter. Huge upgrade from the Nomad 883 Pro.

Nice mixed media. I have a bunch of handmade paper I need to make some honeycomb lamps with the paper on back.

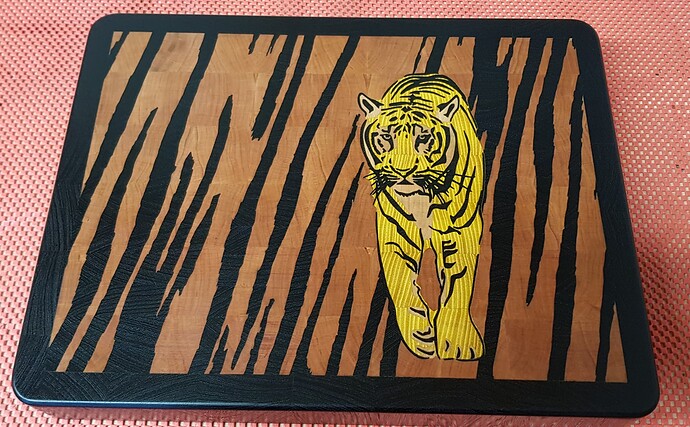

Inspired by a Chinese 2022 Year of the Tiger board made by MTM wood, I thought that I would come up with my own version of a tiger on a background of tiger stripes.

Cherry and Wenge for the background, Osage, Wenge and Maple for the tiger. Finished piece 450 x 350 x 65mm (18 X 14 x 2 1/2 inch). With a 6mm (1/4") inlay. It is a very heavy piece.

It was a challenge but I am happy with the end result. I had to cut a trial tiger in some oak just to check things over, I didn’t want to mess up the expensive cherry, so now I have two.

This design would not work with the types of inlay that have a glue pocket as the VERY small pieces between the whiskers would not be held in place.

Now I have to finish the “trial” version.

What v-bit did you use? That’s some pretty amazing details!

All cuts have been done with a 10 degree v-bit and a 1/8" end mill for clearance.

In Vectric V-Carve.

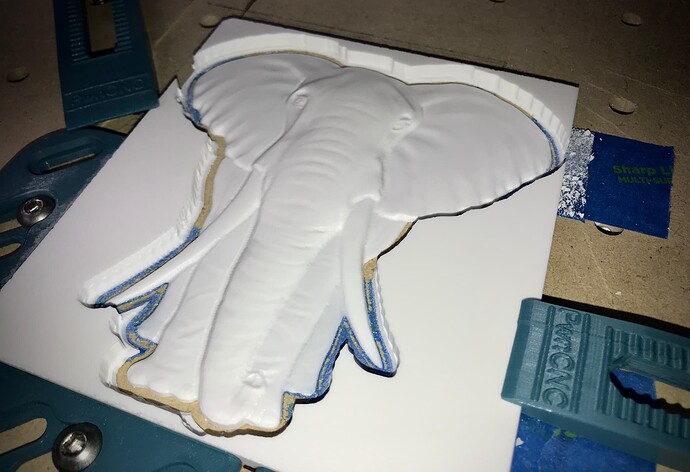

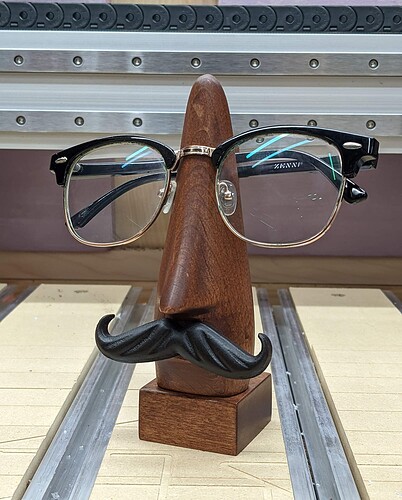

We’re having a “white elephant gift party” at the next family reunion. Thought I’d stir up the group that wants to “steal” the good gifts.

Tex, What type of material is that?

I’ve lost track of the order (for now.) Got a dozen 12" x 12" sheets around 2019. It isn’t HDPE or PVC, because its hard and will chip. Cuts really smooth. I was thinking its PTFE, but I can’t find that in my order history email. I bought it mostly for inlays, and it works really well and long term for that. Speaking of elephants, it polishes up smooth like an ivory keyboard.

I’ve lost track of the order (for now.) Got a dozen 12" x 12" sheets around 2019. It isn’t HDPE or PVC, because its hard and will chip. Cuts really smooth. I was thinking its PTFE, but I can’t find that in my order history email. I bought it mostly for inlays, and it works really well and long term for that. Speaking of elephants, it polishes up smooth like an ivory keyboard.

Is it UHMW? (Which is really just HD-HDPE according to the internet.)

HDPE = high density polyethylene

UHMW = ultra high molecular weight polyethylene

Like I said, I don’t really know what it is until I figure out where I bought it. It isn’t “foamy”. It is stiff and somewhat brittle or “chippy.” Man, it does make some nice chips.

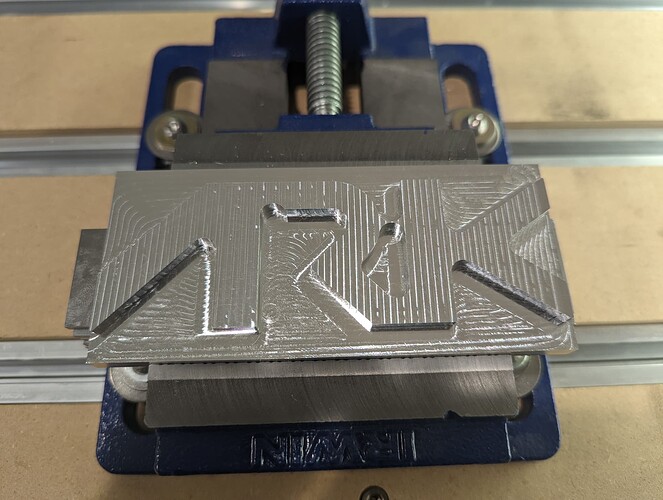

My third attempt to vcarve aluminum on the HDM came out okay. Struggling with tape fixturing that doesn’t warp. The carving is a bit rough around the edges, any advice on how to make it cleaner? This was a 0.1mm deep carve with a 60 degree vbit.

@SLCJedi this is my wife’s lab logo in ortho.

Have you tried the trick of running the job two times in a row ? The second run sometimes acts as a natural deburring pass.

Looks great from here.

I’m with @Julien run it a second time. I’ve also started doing engravings at the highest RPM possible and slow. Seems to come out cleaner.

Hi everyone,

Today, following the awesome guide from @rekluse I tested doing some inlay on my shapeoko 4 pro.

Quite happy with the result

I would actually contend that looks really good, and not unlike what I see before cleaning up. How does it look after sanding down and cleaning up?

…replacing the word concept with contents… ![]()

Cute way to hide your shop bottle. Just wait till work is done.