Great surface finish! Do you mind sharing the recipe for the face mill and the outside contours? I’m guessing you are using the Busch tools face mill? Thanks in advance.

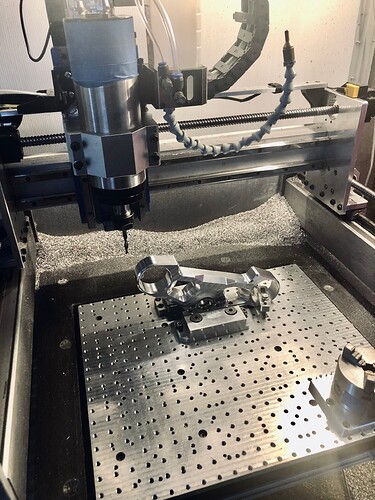

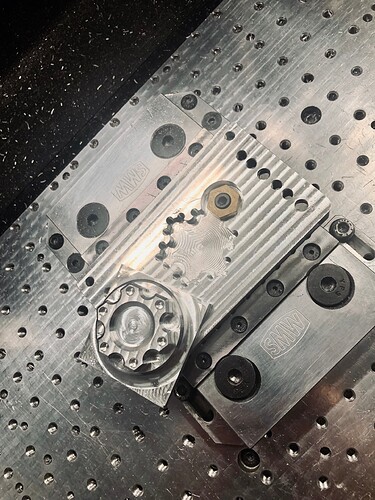

Sure but keep in mind these were starting feeds and have room for improvement.

1" facing mill 10k rpm 25 ipm .015" doc .75" stepover but it can be run faster when roughing. I was going easy on it because I have never run a face mill before.

Contour was a carbide 8mm China single flute 8mm x 32mm

climb cut roughing 18k rpm .25"doc 75ipm .032" stepover. I used ramp set to enter at the front corner and it went in 3 step downs leaving .03" for finishing. The .004" chip load sounded great with zero chatter

Finishing was climb cut 18k rpm .25 doc 35 ipm .03" stepover same ramp and you can’t tell there were 3 step downs used on the finish pass.

I will leave less stock for finishing next time and run roughing harder.

Logo for cabinets using V-groove inlay. I was having terrible luck with early test runs. I finally settled on a Whiteside 60 degree bit (1550.) at 0.1 depth max.

I could not get a good fit at first. I found that my relatively new Carbide Compact Router had significant runout do to a loose top (brush side) bearing. I ran out and bought a Makita router to finish the job. Have other people had this problem with the Carbide router? It started ok, but after about 10 hours (total over a month) of use the router started whining and giving bad results. I can move the spindle shaft back and fourth with my hand.

Let us know about the issue w/ the Carbide Compact Router at support@carbide3d.com and we’ll do our best to work this out w/ you.

I bought a used Shapeoko 3 XL with C3D router. You could wiggle the router shaft. I did as you and got a Makita. I have sense sold the XL and my SO3 XXL with Dewalt 611 router is running well even though I have run the heck out of it. I did have to replace my brushes about 2 months ago after 4 years of running it hard. The C3D router is a clone of the Makita and supposedly uses the same parts but I think the bearings the C3D router maker uses are inferior to the Makita.

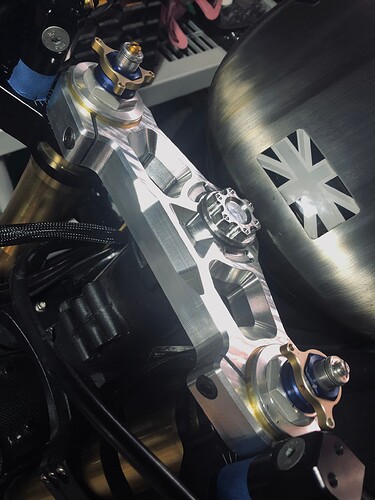

I decided to take a break from the mini engine to build a mini turbine.

Yeah, you caught me. I was lying. These are the flywheels, and flywheels on a Briggs and Stratton engine serve two purposes (technically three). They act as a fan to cool a stationary engine, and rotating mass to help the engine run. Since I was making these out of aluminum they are a little light. So I use some extra stock to mill a lead mold, And then I use the BBQ Grill to cast the lid blanks. They will be finish turned and probably glued or screwed into the back of the fly wheel. These will add about 170 g of additional mass.

Next: GEARS! 26 tooth Crankshaft and a 52 tooth Cam Gear… Oh and yes, they are TINY… They’ll (finger’s crossed) be made on the 4-th Axis. Pray for me…

@BartK wow! Very nicely done!

Very impressive. Just a few light years ahead of my skill set!

My neighbors are great people, both ER nurses (M/F) and recently married. They work very hard, nonstop all the way through the worst of the pandemic, still going and now the wife is 5+ months expecting. I get a frantic call from the husband while he was at work, can you please help my wife, our dog got out of the fence he never ran off before and my wife is extremely upset.

Ran across the street and extremely was an understatement, shes super pregnant, crying hysterically, lost her beloved dog they raised from a pup. So after searching up and down the street, I start driving in a larger and larger radius from around their house looking in peoples yards etc. Soon after her husband left work and raced home, he is out looking with me as well, driving in the opposite direction, and after quite a while I am really feeling sad that there is no sign of him anywhere its about to get dark and I was losing hope. Miles away I pull up on a work truck parked on a side road, someone talking with a neighbor at the end of their driveway and he sees me driving slow looking in yards and leans out of the window as I am slowly driving by and asks: Are you missing a dog by chance? Here is my neighbors dog sitting in his passenger seat like he owns it, panting and smiling at me! The guy just found him and was out driving around looking for his owner.

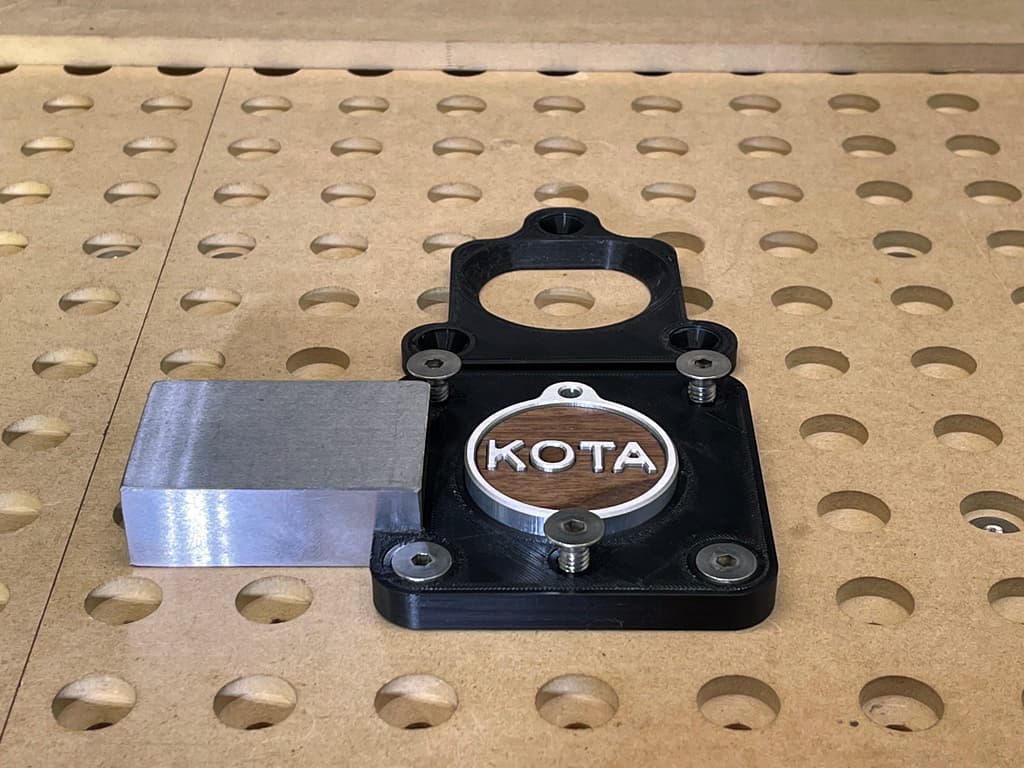

This inspired me to model and carve a dog tag with their dog’s name Kota, (Lucky me only 4 letters ha-ha) and engrave their contact info on the back. Hopefully he never gets out again but this will help if he does.

Going to present it to them tomorrow, hope they like it!

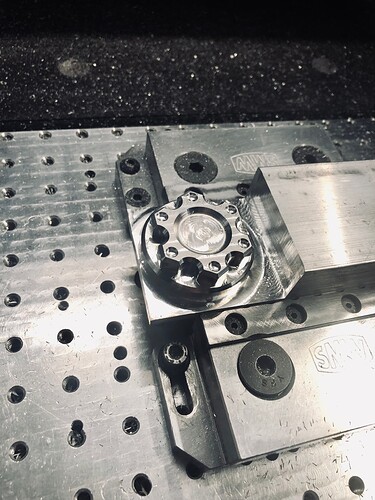

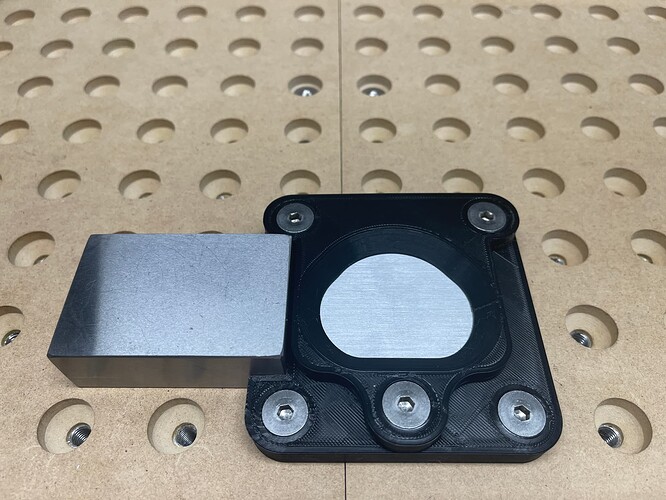

Did something new on this one, I designed a 3d printed jig to hold the tag for back side engraving, as I plan to make more of these in the future. Very easy to just bolt it down, I use the 123 block to probe from. Back of tag blurred for their privacy.

Carved out of 6061 and Black Walnut on my Shapeoko Pro, went down to a 1.5mm end mill to carve out the insert.

Bottom photo has some paper towel dust stuck to walnut oil finish. Did not notice till after I took the pics.

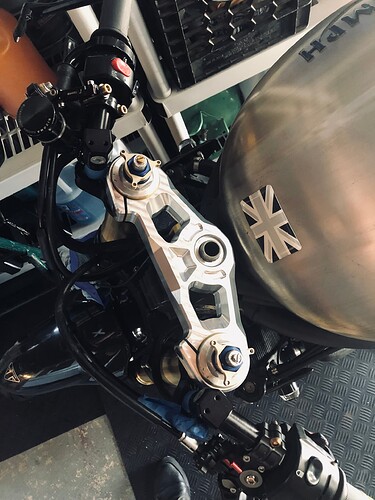

What year and model Triumph? I’m a Triumph owner from the 70’s two T150 and a Hurricane.

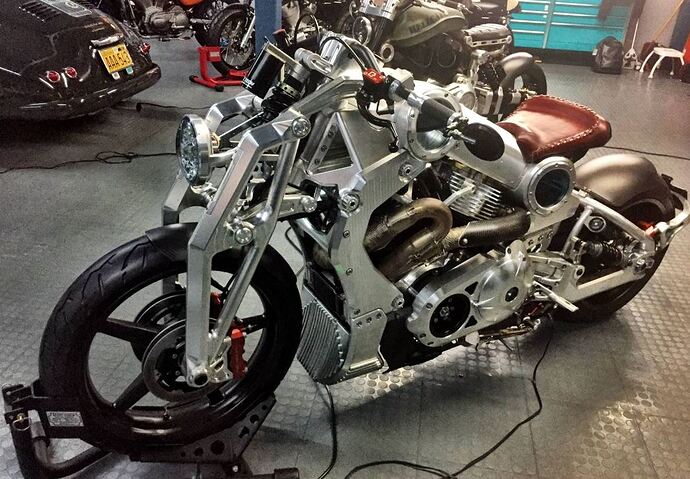

@JohnP Highly modified 2005 speed triple. I also own a 2007 Thruxton 900 that i started converting into a scrambler few year back. Ultimately, I want to design and machine myself a girder front end for the speed triple - similar to the confederate fighters. As soon as I find someone who can help me figure out suspension geometry (length and angle of the links that connect headstock to the uprights).

Twin front vented rotors for stopping! Heavy motor.

Max,

Very nice tag, and good story leading into the project.

Very interesting jig. Is the material held down with the tape/superglue method and the jig just for placement?

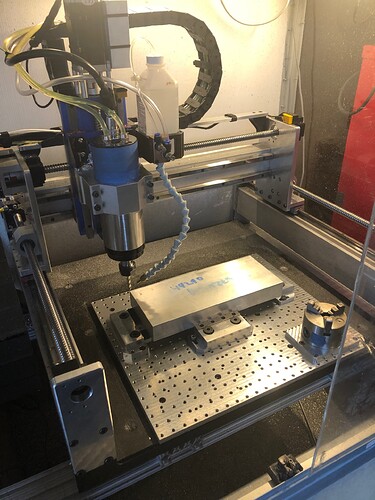

That looks to be an MDF wasteboard:

in a Nomad.

Presumably held down by the tape and superglue method as you surmise:

Yeah, just double sided tape in a Nomad. I actually stained it and put it back in for the photo, the enclosure lighting is great for pictures.

Well, it also nice work, which is good for the pictures!