These are my first cuts using pvc board . I’m loving it … less clean up and much neater turn out … limited colors … but it’s a fave

So is the PVC colored or are you painting it? If you are painting what kind of paint are you using? Nice signs

Thank you . Yes I paint the pvc prior to making my cut . I use krylon from lowes … I use advanced V carve with whatever design I may be using at the time . The last step with the 60 degree endmill … #302 I think … cleans it up nicely . Afterwards I take my tweezers and pull any lingering frays away from the piece . I’ve since learned it might be beneficial to slightly sand the pvc before prior painting and cutting . I’ll be trying that next week ![]() Hope that helps . Have a good day

Hope that helps . Have a good day

Where did you get

the pvc board?

Where to get it depends on where you live. I live in East Texas and cannot find it anywhere. Others say Lowes, Home Depot and Menards carry it. If you have one of those stores look it up on line. I know Lowes lets you order stuff and have it sent to your local store if you have one.

Edit: The PVC comes in two types, solid and foam core. I do not recommend the foam core only the solid PVC. Additionally it comes in 4x8 sheets or as boards that are used a house trim.

I purchased the pvc board from lowes

Looks good!

When working more traditionally, often the mortises are cut first before beginning to shape a cabriole leg or carve the knee. Mostly because the workholding can get funky after the shaping begins as one usually doesn’t leave the large chunks above the knee or below the foot.

Having said that, how do you plan to cut the mortises?

Had a request from my “client” for a stamp. A little back-and-forth and this is the result.

2" x 3" linoleum block from the Carbide 3d store. 1/32" cut depth. 75ipm cutting speed for a 1/8" downcut as well as 60* 1/4" V-bit. All v-carve paths done in Vectric Vcarve-Pro.

I simply included a tool-path for the mortise when the adaptive cuts were completed for that particular side of the four-sided setup.

Thank you! I don’t have that app, but thank you for the direction, search will be my friend.

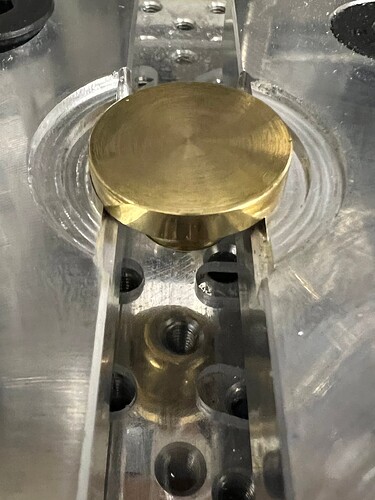

First try in aluminum on the ol shapeoko. these were practice before i make them in brass. Its for my son who is serving over seas. On the snake side i tried to make a 3d model and do a 3d path in v-carve. I think ill re do that to be done with a v bit instead of a ball mill.

That coin turned out really nice.

@nathan32935, what size bit did you use for the white first names? Looks great!

@Macpony, how did you get those great looking edges? Did you do it on the CNC or a router table?

Wow! @Aklimaj, how did you model this?

Hi! I just used an ⅛" bit, I think it was a #102

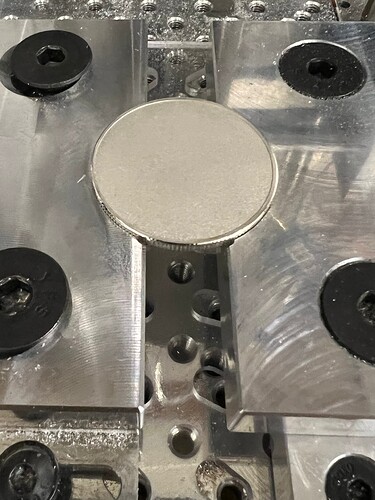

I made some quick soft jaws for holding various sized coins. Hopefully I can produce something as crisp as @m_price ![]()

I have a Saunders Machine Works fixture plate and hobbby mod vise. This is the first time I’ve attempted to cut any custom soft jaws and it worked beautifully. I feel like i could pick up the entire machine by the coin alone. Rock solid hold.

I milled the jaws in a single operation and had them tightly clamped against each other. Not sure if that was good practice or not… anyway the steps are each 1.5mm deep and are cut to hold coins the size of 40mm, 32mm, and 25mm.

@katp I used a router table with a 1/4" round over bit. Heavy for the top and lite cut on the bottom to help square it up. It was a fairly thin board so I did not want to give it a heavy cut. Lots of testing on scrap before I came up something good looking. Thanks for the comments. ![]()

I made more simple things on my cnc over last few weeks nothing fancy or complex but makes great birthday gifts.

Fun projects there. Pieces like this is where a CNC machine really proves it’s value.

I cut 2 pcs. of the lower brown sculpture you showed, back in May for a guy who had tried to do them by hand at first. Saved him weeks of work, I’m sure.