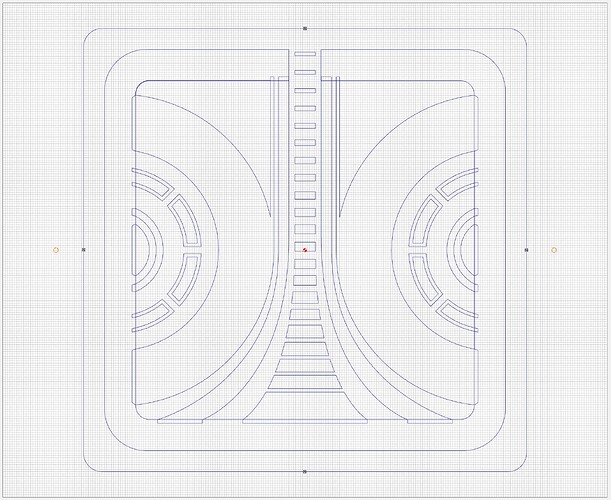

The image below is from my last two-sided job. The design is 12x12 and the material I used was roughly 16x13 and not square.

The red (selected) holes outside of the design are my flip-holes. They are 13.5 (center to center) apart from each other which lines up with my waste-board threaded inserts.

Step 1 is I drill out these holes, and it does not matter if I’m off center or my material isn’t perfectly square. At this point it’s just two holes 13.5 apart, the right size diameter for my threaded inserts. I then bolt the material down to my waste-board.

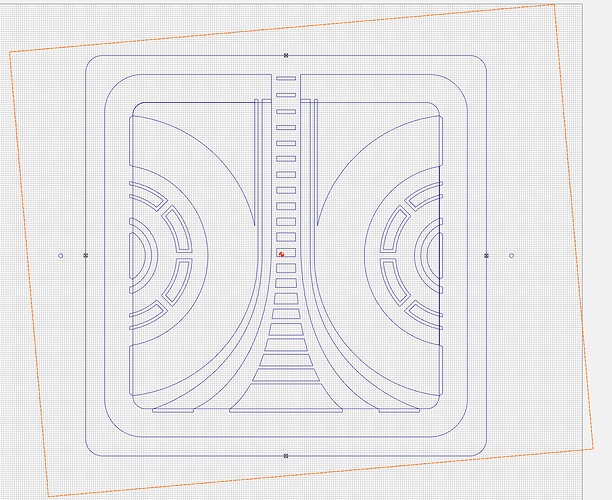

So even if my material was REALLY off (pretend the highlighted square below was the edge of my material)…

… when I flip it over, as long as I re-bolt into the same threaded inserts my design is still centered in reference to the two holes. I do NOT change my zero settings, I just run the job for the other side.

It’s basically the same concept as doing “tiling”, instead of moving the material you’ll be flipping it over.