Yup - that’s why high cutting speeds (RPM/SFM) are so helpful for CNC Routers. They help mitigate the impact of the lack of machine rigidity and feed force. What is the “most ideal material’s SFM”?

I couldn’t disagree more!

As @Vince.Fab and others here and elsewhere have demonstrated, high speed machining (HSM) techniques can provide significant increases in the capability of CNC routers, including Shapeokos and Nomads because of the cutting force reductions they enable.

An explaination of why HSM works (as of 1977) from page 16 of the Handbook of High-Speed Machining Technology:, "Almost all of the energy of metal cutting is used for plastic deforming of the chips and in overcoming friction between chip, tool, and workpiece. All of these actions result in heat, and that fraction dissipated in the tool causes softening and reduced resistance to abrasion, thus limiting tool life. Consequently, the crux of the problem of super-high-speed machining is to concentrate the heat in the chips and minimize the quantity of heat transfer to the tool.

It is postulated that the heat generated per unit volume of metal removed should be lower at very high speeds because ductility of metal decreases with increasing strain rates. In addition, if the heat accompanying deformation is confined to the chips, chip temperatures will be raised and their strength reduced. Unfortunately, the available data do not permit quantitative estimates of importance of temperature and strain rate on the energies required for deforming chips at excessively high speeds.

In addition to the points discussed, high-speed metal cutting seems feasible on other grounds. It might reasonably be expected that the tool would not reach a high temperature, even when the heat liberated in the chip is higher per unit of time, because the time available for conduction is limited by the high speed…"

All of this is really interesting, thanks for putting so much into this post. You guys have brought out some great information.

I find this piece of info on high speed machining especially interesting. I’m very curious on what I see missing in this explanation. When a chip is cut and it leaves with thermal energy imparted on it. Yes that makes sense but what about the heat imparted on the cutter and the piece?

I can guess that the chip is heated by the deformation it experiences while being cut (as how the chip comes out bent), but I have to be curious about the other sources of heat, and how those affect the work piece and cutter. Thermal conduction is bound to happen between all points of contact, but due to the high speeds I doubt this is a major contributor to heat in any of these elements (i’m looking into it though. please).

Also of people have talked about heat generated due to the rubbing that happens between the cutter and work piece as a major contributor, and my intuition seems to agree with this. Since the cutter isn’t infinitely sharp there’s bound to be aluminum left on the wall as the cutting edge passes along it, and that I’d guess bounces back and rubs against the rest of the cutter beyond the cutting edge. That’d create heat as well as deflection. I looked a bit at an end mill and I noticed there’s a slice along the side of each flute, and I’m guessing this is to reduce friction. However it doesn’t get rid of all of the side, so there’s still some contact.

A friend of mine pointed out that energy is also released when the metallic bonds are broken, but I’m still figuring out how to calculate that cuz that means somehow calculating how many atomic bonds are broken when a chip is cut.

Yeah so if you didn’t feel like reading that, what are the sources of heat that heat the cutter and work piece in a cut?

There is another very long thread about these topics that you shouldn’t miss. I think you’ll be interested in it. It starts out a little slow, but the conclusions are a blockbuster! ![]()

If any of y’all want to test some high rpm/sfm stuff, I found a site that sells 3/8s single flutes pretty affordable. They also have diamond coated and SF ball mills.

Yup! This is correct and a much better description than mine. I think the important clarification you asked about above is you want to elevate the temperature of the chip as much as possible but if you could magically keep the cutter cool, that’s ideal. This is the idea behind cryogenic machining; you still get all the heat generation from deforming the chip but the cutter stays super cold and cold is strong:

Cutter and chip thermal transfer is why chip load (thousandths per tooth) becomes important, if the chips are too small, they don’t have enough thermal mass and will start locally welding to the tool. High speed machining (HSM) with low radial engagement and high axial engagement is nice for other reasons as well; there is just more room for the chips to go somewhere and not be recut. Chip recutting is a leading contributor to ruining cutting tools quickly. This is why horizontal mills are so productive, chips tend to fall away from the part instead of back onto it to be recut on a vertical. (Man, this is turning into a ramble.) Chip formation and temperature effects are the reason climb milling and not conventional is used in almost all cases; in climb the chip thickness goes from thick to thin. Climb milling heat generation happens rapidly in the beginning of the cut but there is enough thermal mass to not melt and by the end of the cut, the chip will shear or pull off as it gets thin. As always, Sandvik explains it better than me:

HSM also makes sure longer endmill cutter length is engaged; sure is nice to recycle a carbide endmill with all the flute length dull than just the bottom 10% for example.

Ok, last thing and could be controversial but is interesting, HSM at the machine is primarily a software problem. Really. The HSM option from Haas for example is all software and what it does it called a ‘look ahead’. HSM has lot of cutter direction changes happening all the time and machines are heavy. Conventional g-code is point to point, line by line execution whereas a CNC with look ahead will start changing direction earlier based on what positions are in the next several lines of g-code.

Ok, seriously last thing because I can’t help myself. Most controversial opinion; your natural intuition in metal cutting is probably wrong, when a cut is loud or chattering you will want to decrease the feedrates…which generally causes more chatter. Sounds nuts, but incrementally increasing the feedrate solves a lot of problems whether you are on a Nomad or a 7 figure mill turn machine.

I’ll see myself out…

Nice write up!

I’ve seen others refer to that as HEM (High Efficiency Machining) rather than HSM (High [cutting] Speed Machining). A new one for me was High Feed Machining (HFM?) as shown in the following video (seems counterproductive to me!)

You are asking the question that I wanted to know about as well and answered in a prior post (although these forums are impossible to search and find anything in). I didn’t quote all my sources, I was in a bit of a rush that day and did end up quoting some of them later.

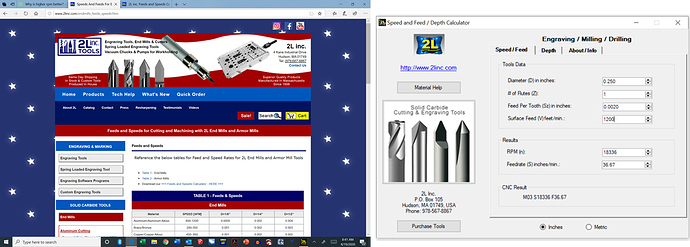

Maximum 18336 RPM for Aluminum and 27504 RPM for Plastics according to their speeds and feeds.

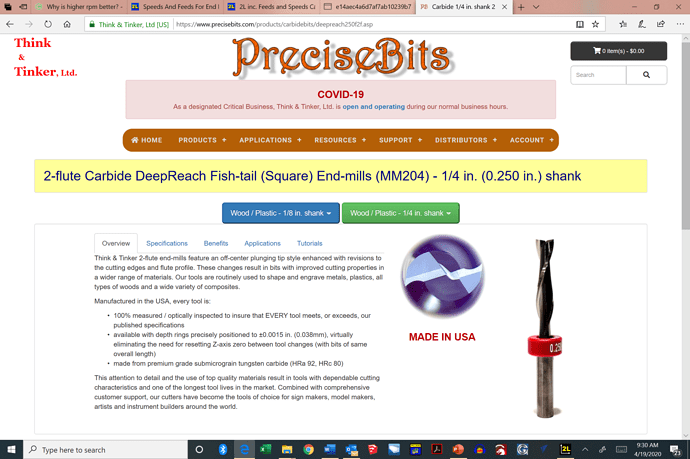

PreciseBits has several ~$30 2 flute 1/4" wood and plastic cutting endmill that’s “CNC Certified” for 60,000 RPM, but they seemingly don’t show speeds or feeds for them.

$5 says we can push to 3,000 sfm with little issue and good cam. $25 and I’ll hit 4,000ish (enough to pay for the tool)

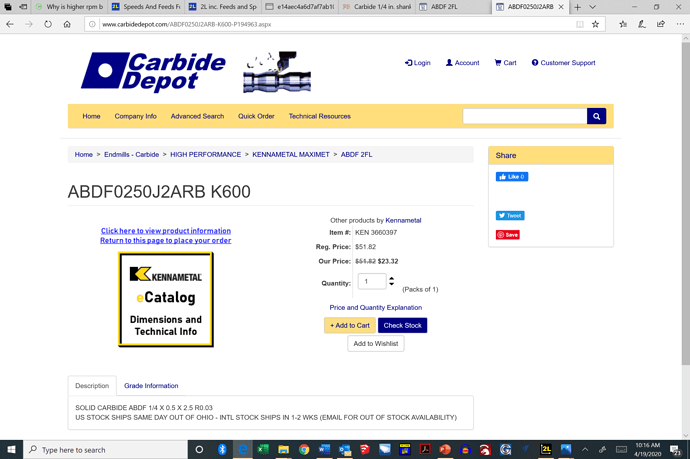

Or, for $23 you could get a 1/4" 2 flute endmill rated for 4920 SFM (75128 RPM) operation in Aluminum.

Three reasons, Torque, chip clearing, and feed requirements increase too much.

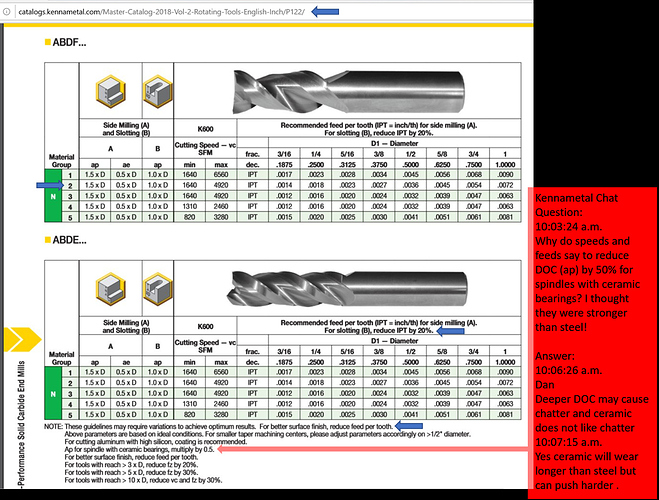

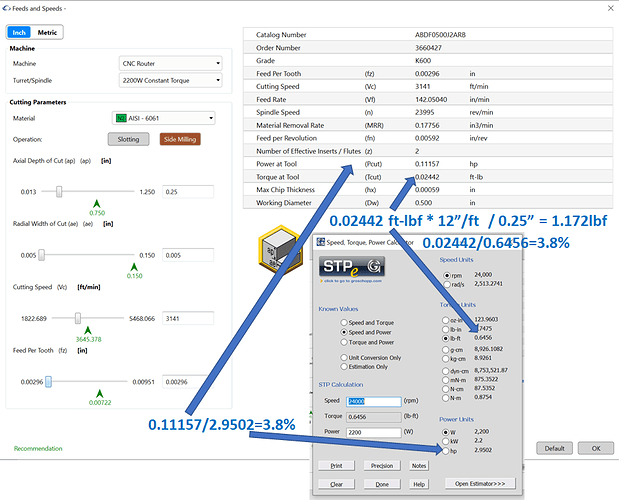

Here’s what Kennametal’s newest “most accurate” speeds and feeds calculator (embedded in their NOVO App suite) predicts one of their 1/2" $50 endmills should be capable of in @Julien’s 2200 Watts, 24,000 RPM G-Penny constant torque spindle. Note that less than 4% of the Spindle’s available torque and power should be required. Most importantly, the cutting force should be less than 1.172 lbf, which even stock Shapeokos should be able to handle. Unfortunately, unlike their older online calculator, the new one doesn’t calculate cutting forces (which are equal to torque divided by half the cutter diameter).

For safety and performance reasons, it’s probably wise to use properly rated tools (endmills) and tool holders. Increasing cutting speeds imposes increasing demands on both. Reasonably priced high speed/performance endmills are available from Carbide Depot (their website also provides some excellent technical resources/links.) High speed/performance Techniks tool holders are available from Amazon.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.