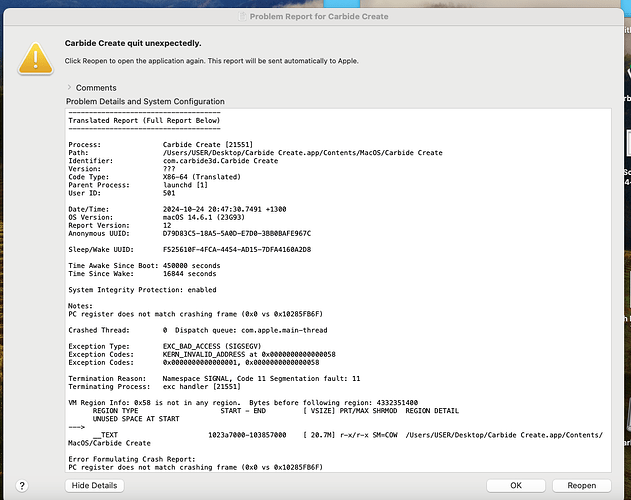

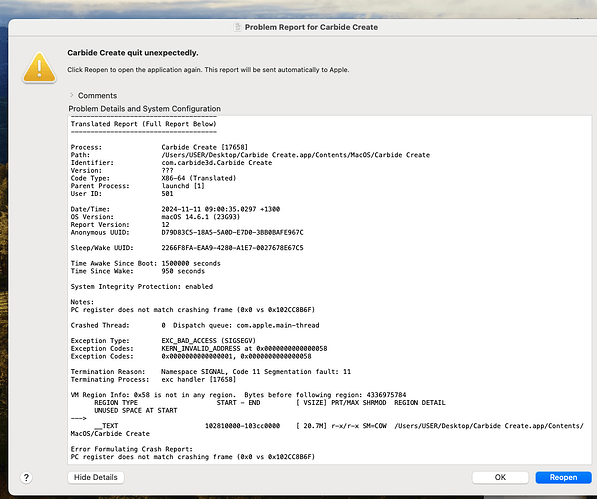

Hi my 805 crashed overnight here is the report

Any plans for dxf exporting for CC Pro? I have been designing parts in CC Pro and it would be great to export to dxf instead of svg. Currently I use Lightburn or Vcarve to open an svg and then export to dxf from there. Would be nice to skip this step if possible.

I am using V8, editing a design created in V7. The design has existing tabs, and I wanted to eliminate some as there were more than necessary.

When I selected the vector with tabs, then clicked the edit tabs option, all existing tabs were eliminated. No big deal, I just re-set the tabs I wanted, but now you know.

I wasn’t able to replicate that — could you upload your file here?

False alarm, so sorry. The tabs disappeared when I changed from inch to mm, which slightly resized the rectangle. All is well, and V8 is great!

There is a current country song that the lyrics are

“God is Great”

“Beer is good”

“And People are Crazy”

So lets say CC v8 is good.

Can we have the ability to use t in design dimensions without it automatically, onetime changing the value?

Currently we have a situation where if you put t in the current thickness is substituded as it is at the time of entering t. If you change your stock thickness later, this value currently does not get updated.

( See also Using symbol for heights )

When you use the “t” CC looks at your material height and automatically calculates the depth when you save the .c2d file. For instance you set the height to .5" and save your file. Automatically any tool path is set to go down .5". However after you get the material on the spoilboard and it is .625" change the material in setup and save and the tool path is automatically updated to .625".

I understand that you can also use the “t” to go over or under the material height dimension. I have not personally used that but have seen it here on the forum. I think it would be “t-.01” to leave 0.01" at the bottom without cutting through. Also I understand that “t+.01” would cut 0.01" below the bottom of the material. Hopefully others that have used the t with the additional parameters will chime in.

I find the “t” very handy because tool paths are automatically updated but only by saving the file. I often design with a nominal thickness but change my CC file when I get the actual material up on the spoilboard and measure it. I usually design to my need for something and then find material that matches my requirement. I have a lot of wood in my shop so it is easy for me to find something and change the thickness on the planner. In older versions of cc when tool paths were calculated the setup material height was used. If you changed the height in setup the tool paths were not automatically updated when saving and you had to edit each tool path manually. The “t” was introduced some time ago and I have been using it for some time. Using the “t” is very handy and automatically updates without my manual intervention.

t doesn’t work for example on height/width in design mode the same way it does in toolpath mode. In design mode it’s a one shot conversion converted to a fixed number - the thickness of the current material. If you later change the thickness, design mode t values do not change in sync.

Things like dados depend on material thickness, I’m asking that we can use t in design mode and that it will honour t if you change the thickness.

Probably not (or at least not now) for a couple of reasons:

- That heads into “parametric design” territory and if we do that, we need to look at how to make it clear to everyone why their design is changing “randomly” or why “it’s doing whatever it wants.”

- The document model doesn’t have a way to link a dimension in a shape to a variable, so this would be a huge change.

We just uploaded 807 to Carbide Create Beta Downloads

- (Pro) Added Facing toolpath.

- (Fix) Fixed crash for improper, manually-edited CSV tool database files.

- (Fix) User reported crash in pocket code.

- (New) Allow V/engraver cutters to be used for 3D toolpaths.

- (New) Force higher calculation detail for 3D toolpaths with small cutters.

- (Fix) Removed Library->Import from URL

- (New) Add url handler to eventually be able to send a link with a license code.

The Facing toolpath has not been tested thoroughly, but it looks good so far. Let us know how this build works for you.

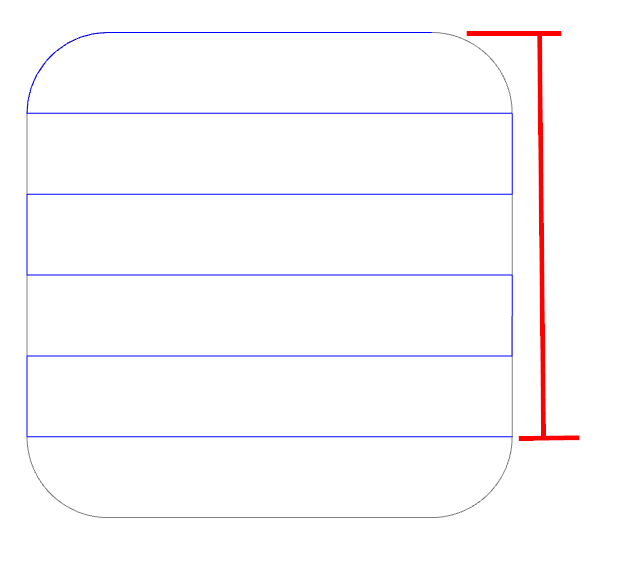

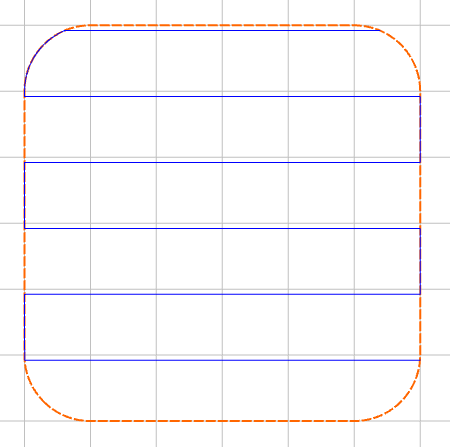

Facing Toolpath.

Stepovers occur right on the boundary. Cutting passes are offset inside the boundary, and not evenly???

After we have reported bugs to Carbide support, is there a way to see some kind of roadmap or plan for fixing the bugs? We know plans change, just would be nice to know how that reported bug was prioritized.

We don’t have any public bug tracking.

What kind of stepover was the bit set for in your test setup?

I just tried with a couple different sizes of endmill & stepover values & the toolpath seems to start the first pass 1mm less than the stepover value from the lower edge. Then subsequent passes use the actual stepover value until the last.

808 is up at Carbide Create Beta Downloads

- Facing and 3D roughing toolpaths now center the raster passes within the area to machine.

- Change the way the data directory is shown on Mac to eliminate delays.

- Pockets with a stepover larger than the tool radius get extra checks to see if uncut areas remain.

- Better handling of imported DXF/SVG files with duplicated/overlapping segments.

Just a question about the surfacing toolpath:

Will it just be a basic raster path? Any plans to make it more customizeable?

I’m curious cause a couple weeks ago I discovered how much of a difference the direction of cutting makes when surfacing sometimes. Specifically how much more power it takes for a router/spindle to be pushed across the surface in the Conventional direction vs Climb on hardwood like maple. And when using a 1" or 1-1/4" surfacing bit, it makes quite a big difference.

So I guess what I am asking is if there would be any development for surfacing toolpaths which would only work in Climb/Conventional fashion instead of mixed?

We’re open to adding “Climb/Conventional/Either” if this is a feature that gets used.