Hi folks,

It’s been a while since the last round of community challenges and/or Carbide 3D contests. Case in point: unless I am mistaken the latest winner was @Luke, see where that got him  !

!

@Jorge asked me to revive this community tradition, and he will be providing great prizes from Carbide 3D store for this series of challenges. We will make this a fortnightly thing, if you guys are game.

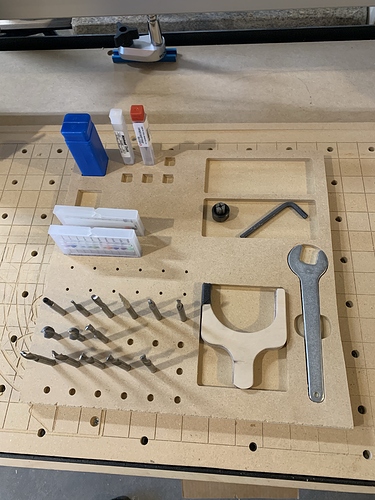

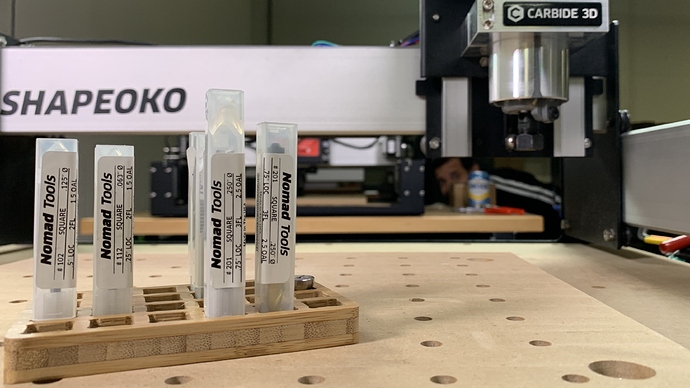

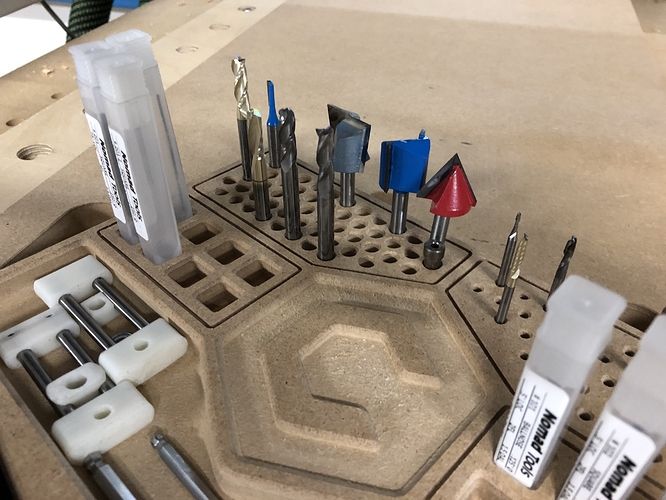

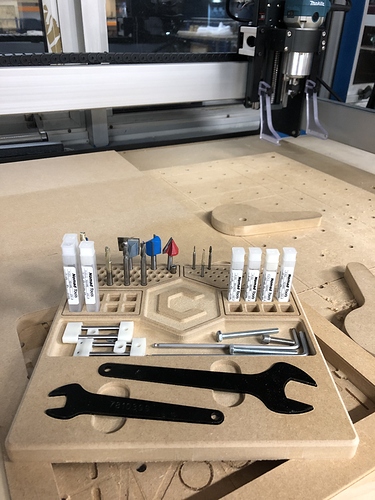

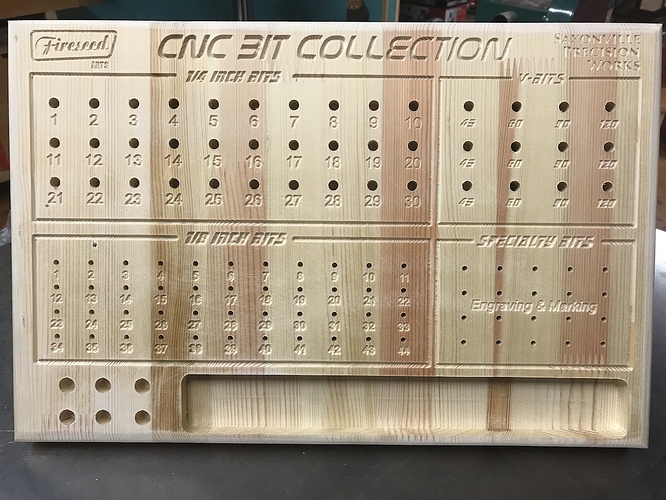

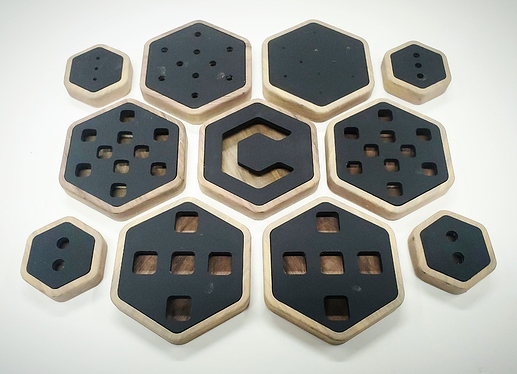

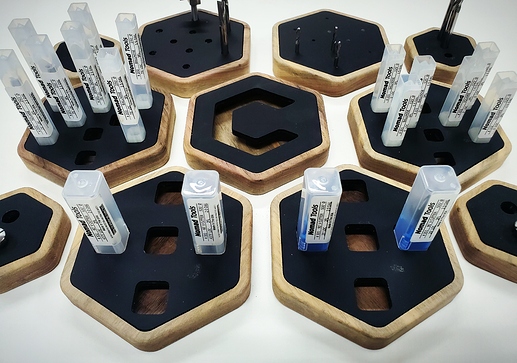

Challenge #1 is: make a bits & collets holder

Rules:

- it must be made on a Shapeoko or Nomad

- submit your entry in this thread:

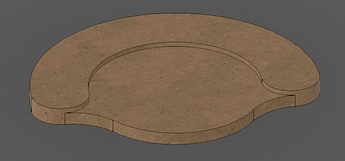

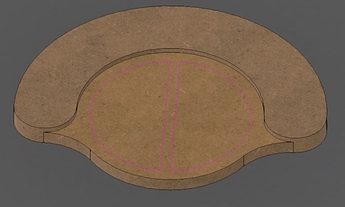

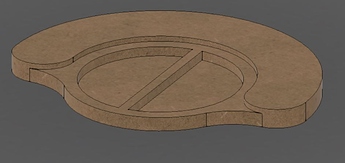

- post pics of the finished piece

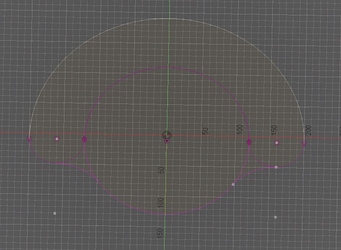

- include the associated design file(s) and tell us about the steps you followed to create it.

- any CAD tool welcome, bonus points for using Carbide Create.

- you can post multiple entries if you want.

If you are just starting with the Shapeoko or Nomad, don’t be shy: it doesn’t have to be fancy, the point is to get your feet wet, share your experience with the community, and possibly win some cool gear in the process.

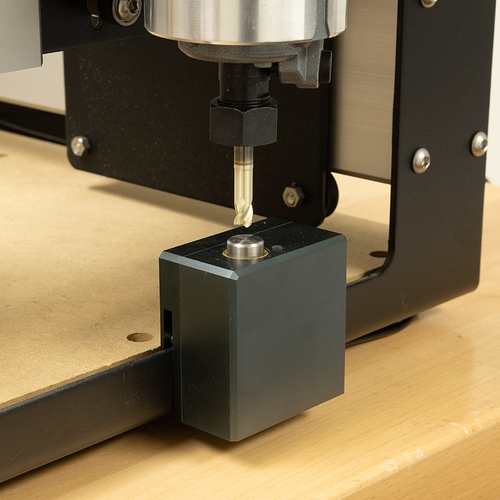

And to kick off this series in the best way possible, the prize for this first challenge is…the brand new BitSetter announced earlier today! The winner will be among the first ones to get one, how awesome is that ?

To use such a cool device you will need to look the part, so you will also receive this funky Carbide 3D swag pack!

The winner will be selected based on the number of likes, ties will be settled based on originality, quality of the post, enthusiasm, and as a last resort @Jorge’s ruling hand.

The deadline is 10 days from now, that’s Dec 12th (say midnight PST).

Let the challenge begin, and let’s see your bit holders !