Has anyone done a 4th axis (manual or cnc) on their HDM? I looking for ideas

What kind of 4th axis? Which axis does it rotate around?

Gearhead Mike made a turntable that allows him to turn round parts using a spinning mill to do the cutting. This is a “C” axis (rotates around Z) No Cutter Compensation G-codes G42 & G43 for Shapeoko?

I’ve seen a few guys made indexing rotaries that allow rotating the part to cut multiple sides.

Some manual, some controlled by swapping out the Y or X axis from the controller.

IF the part is mounted left to right so it rotates around the X axis, this would be an “A” axis rotary.

I mounted a little Dremel Lathe to my table & zeroed on the centerline of the lathe and used just my X & Z axis to turn a part. This would also be a “A” axis rotary.

Im thinking a manual A axis would work ok if i can find the time to test

Those are beauties! Great job and good too see what my Pro can do.

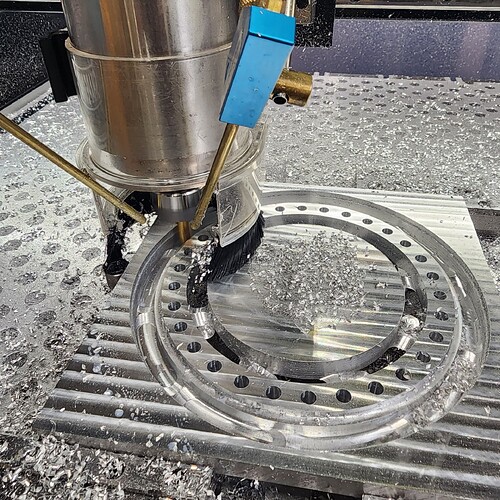

Some cuts I made today, I diddnt want to push the machine. Its my third cut in metal on this machine. Facing passes were done with a dlc coated 10mm 3fl 18,000rpm 2000mm/m 0.75mm doc 7mm step over both ways with no changes to lead in lead out.

https://i.imgur.com/xeeAREw.mp4

https://i.imgur.com/4uRwI3u.mp4

I think I am going to add a second air blast as I can see where im chip recutting or heating up some on the side that doesnt see air. Finishing pass was .15mm radial full doc with the 10mm 19,000 1500mm/m with a wipe of wd40 on the endmill and face before slicing.

Also I think im gonna up the rpm on my chamfers.

What are you guys doing about chips landing in the linear rails? I am getting so much chip that im stalling the machine when it homes after a cycle because they are caught up in the ways of the rails.

Anyone elses machine get caught on chips and stall alot? Ive had it happen 4 times now and im taking healthy chip loads, its getting aggravating having it happens 90% through a job. I vaccum every time i run and it still does it at random intervals on random axis. Really considering ditching all the electronics and buying real drivers for the steppers.

There are lots of advantages to new electronics but they will not solve that problem. If chips are building up and causing missed steps, you need to figure out how to prevent the chips from building up. A discussion on this might be better as it’s own thread rather than appended to the end of this one.

Have you tried a powerful shop vac combined with a Sweepy? I have had great success with this method carving aluminum and wood.

I have only had that issue if I I didn’t blow off before the machine homed, it went all the way to the end of travel, then compressed a pile of chips. I have not had it happen in normal operation. Unless you’re cutting to the end of the travel of an axis, there is nothing for it to pack up to and stall the machine.

Josh,

Saw this years ago. Maybe it will help.

That is an interesting implementation. I think it would still sit proud and reduce travel though.

I’ve got a couple ideas kicking around on my head I need to find time to try.

I have a spare 200w hydroponics air pump sitting idle so I’m thinking to add 2 nozzles on the X axis aimed at the ball screw to clear chips off the screw and rails during operation. I also thought about making another half brush guard collar for the spindle because that kept 95% of the chips off my So3 rails but still allowed for chip evacuation and tool change without having to remove it each time.

I will look for that old post.

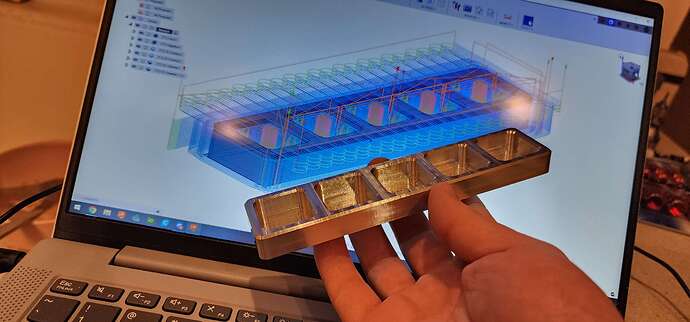

3fl dlc coated 10mm 18,000 rpm 0.75mm doc and 7mm step over doing some facing.

Was aiming for 10mm thickness

Finished part, its a bracket to relocate my tool setter on the nomad for some mods I’ve done on it (will post a post about it in the unsupported section when its finished). Bracket is v2 because I set a zero wrong on v1 and plunged a .35mm chamfer pass 4mm deep into the hole. Live and learn. Used a 10mm 3fl, 6mm 3fl, 1/8th 2fl, 6mm 3fl chamfer, M6 thread mill and a drag engraver for this part. Please don’t make a deal about the engraving, its just a joke lol.

Was messing around with a 3 flute carbide welded mdf face mill today. Will soon be picking up an indexable insert head and some inserts to hopefully get a full mirror instead of almost one but it still came out nice

17mm deep finishing pass with a 10mm dlc coated 3fl, Last one was 0.04mm stepover.

Part after it was finished up

Anyone ever put together tool list for aluminum?

Ive found that for the most part for 99% of things DREANIQUE tools on aliexpress do the job. Much cheaper then other brands, tools last just as long. The downside being that they take longer to get and dont offer the same variety of high end tooling features like radii corners and high helix. I get almost all my work done with 1/16th 1/8th 2fl, 2fl 4mm, 3fl 6mm and 3fl10mm + a few threadmills and 90 degree chamfers and ball mills

No single flutes? I was going to start with more traditional 2/3 Flute as I have access to them but looking hard at single flutes.

I personally dont use them. I dont slot anything.